Investing in flow measurement without understanding accuracy limitations can lead to costly process control errors and wasted resources.

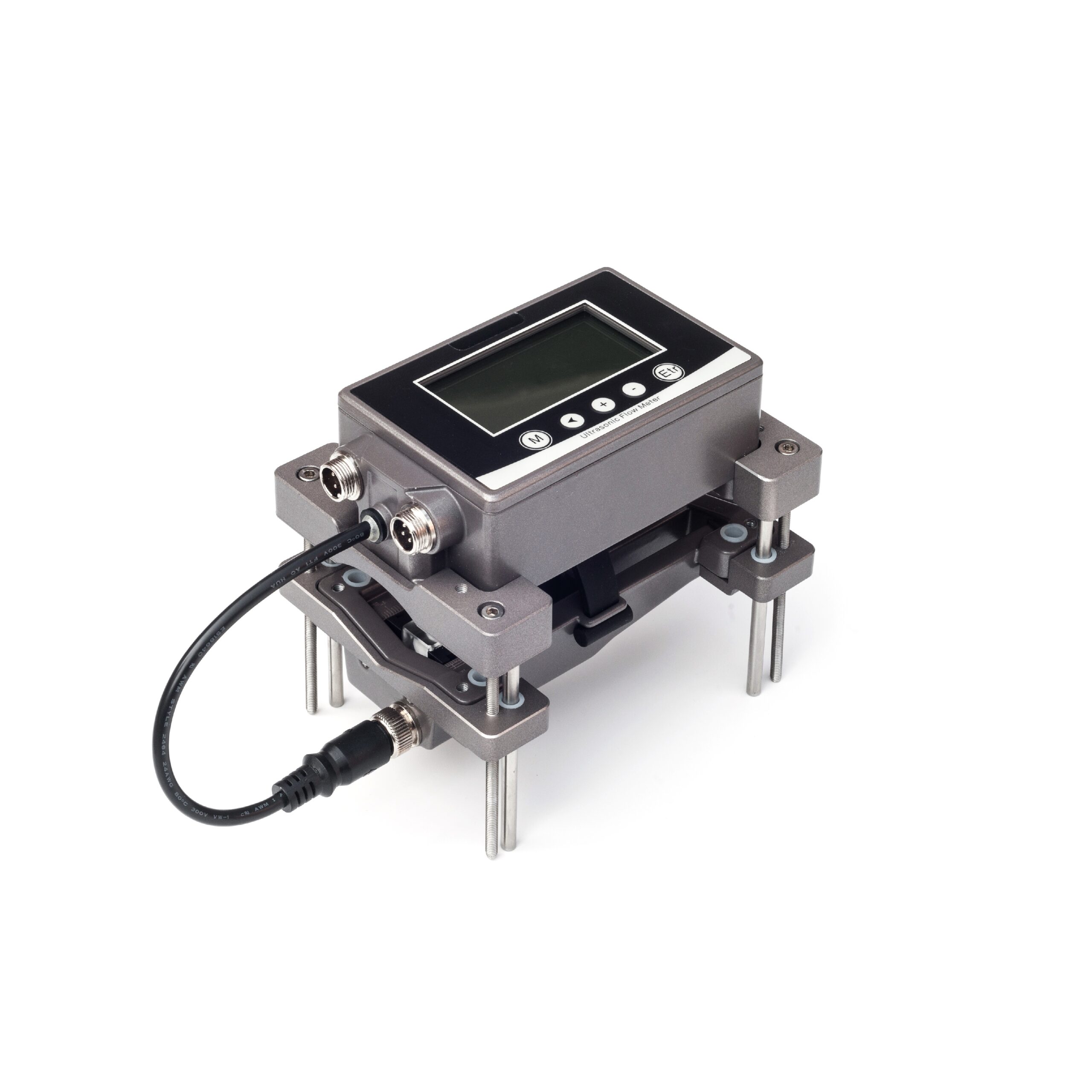

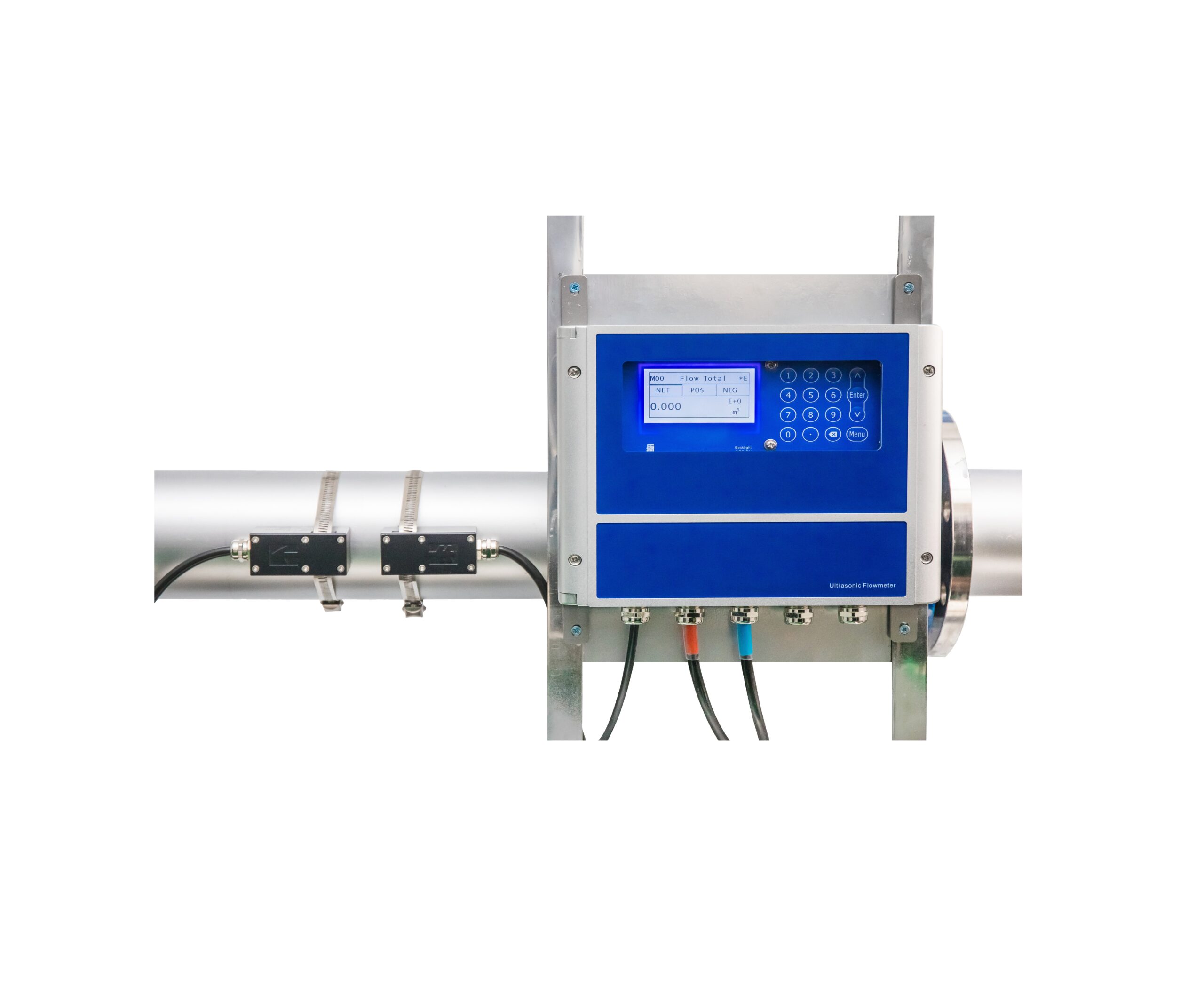

Ultrasonic flow meters can achieve accuracy levels of ±0.5% to ±1.0% of reading under optimal conditions, making them highly accurate for clean liquid applications.

Ultrasonic Flow Meter Accuracy Overview

Let me share insights from my experience with ultrasonic flow measurement technology.

How Accurate Are Ultrasonic Flow Meters?

Process engineers often question whether ultrasonic meters can meet their stringent accuracy requirements.

Modern ultrasonic flow meters achieve accuracies of ±0.5% in liquids with proper installation and stable flow conditions, rivaling traditional technologies.

Flow Meter Accuracy Comparison

From my field experience:

Accuracy Factors

-

Performance Analysis

Condition Typical Accuracy Best Practice Impact Factors Ideal ±0.5% Straight runs Flow profile Standard ±1.0% Good installation Pipe condition Challenging ±2.0% Special setup Flow disturbance Gas/Steam ±1.5% Higher frequency Fluid properties -

Installation Effects

- Upstream conditions

- Downstream influences

- Mounting position

- Pipe characteristics

Optimization Methods

-

Setup Requirements

- Proper straight runs

- Correct orientation

- Signal strength

- Flow conditioning

-

Maintenance Needs

- Regular calibration

- Signal verification

- Transducer cleaning

- System checks

What Are The Disadvantages Of An Ultrasonic Flow Meter?

Understanding limitations helps avoid unexpected problems in ultrasonic flow measurement applications.

Key disadvantages include sensitivity to installation conditions, higher initial cost, and potential issues with fluid properties like entrained air or particles.

Ultrasonic Flow Meter Limitations

Based on my implementation experience:

Common Challenges

-

Technical Limitations

Issue Impact Solution Prevention Installation Accuracy loss Proper planning Site assessment Air bubbles Signal loss Air elimination Process control Particles Signal scatter Filtration Fluid treatment Cost Budget constraints ROI analysis Project planning -

Application Constraints

- Space requirements

- Environmental factors

- Maintenance access

- Skill requirements

Mitigation Strategies

-

Design Considerations

- Site evaluation

- Installation planning

- Performance monitoring

- Staff training

-

Operational Solutions

- Regular maintenance

- Performance checks

- Troubleshooting procedures

- Documentation

What Is The Most Accurate Type Of Flow Meter?

Finding the most accurate flow measurement solution requires understanding various technologies.

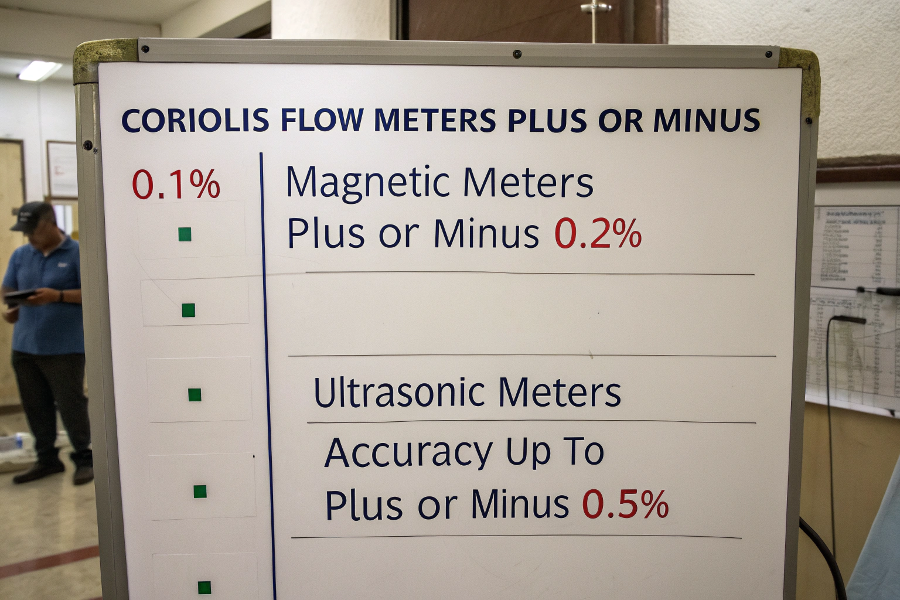

Coriolis flow meters provide the highest accuracy (up to ±0.1%) across all flow meter types, followed by magnetic (±0.2%) and ultrasonic meters (±0.5%).

Flow Meter Accuracy Comparison

Drawing from my expertise:

Accuracy Comparison

-

Technology Rankings

Meter Type Best Accuracy Application Limitations Coriolis ±0.1% Mass flow High cost Magnetic ±0.2% Conductive Conductivity Ultrasonic ±0.5% Clean liquids Installation Vortex ±0.7% Steam/gas Reynolds number -

Selection Criteria

- Process requirements

- Fluid properties

- Installation conditions

- Budget constraints

Application Guidelines

-

Decision Factors

- Accuracy needs

- Operating conditions

- Maintenance capability

- Life cycle costs

-

Implementation Steps

- Technology selection

- Site preparation

- Installation planning

- Performance validation

What Is The Uncertainty Of The Ultrasonic Flow Meter?

Understanding measurement uncertainty helps ensure reliable process control and compliance.

Ultrasonic flow meter uncertainty typically ranges from ±0.5% to ±2.0%, depending on installation conditions, fluid properties, and calibration quality.

Ultrasonic Flow Meter Uncertainty Factors

Based on my field experience:

Uncertainty Analysis

-

Contributing Factors

Source Impact Level Control Method Verification Installation High Best practices Site audit Calibration Medium Regular checks Standards Electronics Low Diagnostics Testing Environment Medium Protection Monitoring -

Management Methods

- Uncertainty calculation

- Error analysis

- Quality control

- Documentation

Improvement Strategies

-

Reduction Methods

- Calibration program

- Installation optimization

- Environmental control

- Maintenance schedule

-

Verification Process

- Regular testing

- Data analysis

- Performance trending

- Documentation review

Conclusion

Ultrasonic flow meters offer excellent accuracy when properly installed and maintained, but success requires understanding their limitations and following best practices for installation and operation.