The majority of wall mount ultrasonic flow meters on the market today still use a decades-old design: a plastic enclosure with a small, monochrome LCD screen.

While this configuration gets the job done initially, it often fails to meet the demands of long-term industrial use. Plastic degrades. Screens become unreadable. And technicians waste valuable time navigating confusing menus.

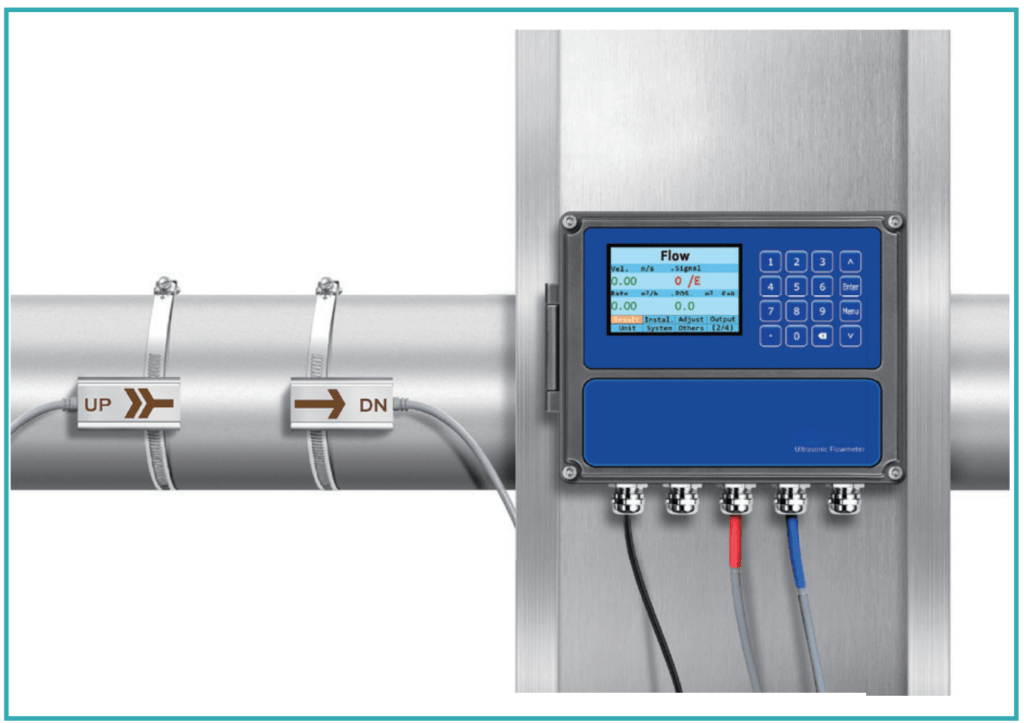

The new generation of flow meters is changing this paradigm. Products like the Soaring SR6100S-II are introducing full-metal enclosures and high-resolution color TFT displays to address these long-standing pain points.

In this article, we’ll explore why these two features—industrial-grade durability and user-friendly visualization—are not just upgrades, but necessities for modern flow measurement.

The Problem with Plastic Enclosures

Plastic (ABS or polycarbonate) enclosures dominate the market because they are inexpensive to manufacture. But in a real-world industrial environment, "cheap" often translates to "failure-prone."

1. UV Degradation

For outdoor installations or even indoor locations near windows, plastic is a ticking time bomb. Ultraviolet radiation causes the material to become brittle over time. After a few years, the casing can crack, compromising the IP rating and exposing sensitive electronics to moisture and dust.

2. Poor Impact Resistance

In busy mechanical rooms and factory floors, accidents happen. A dropped tool or a ladder bump can shatter a plastic housing. The SR6100S-II’s aluminum alloy enclosure is built to survive these daily knocks.

3. No Electromagnetic Shielding

Industrial environments are electrically noisy. Variable frequency drives (VFDs), large motors, and radio transmitters generate electromagnetic interference (EMI) that can affect sensitive measurement circuits.

Plastic: Completely transparent to EMI. Interference passes directly through to the electronics.

Metal: Acts as a natural Faraday cage, blocking external noise and protecting measurement accuracy.

The Metal Enclosure Advantage: Four Key Benefits

The SR6100S-II features a full aluminum alloy enclosure rated IP65. Here’s what that means for your operation:

| Benefit | How the SR6100S-II Delivers |

|---|---|

| EMC Shielding | The enclosure’s excellent electrical conductivity blocks electromagnetic interference from VFDs and motors. |

| Thermal Management | High thermal conductivity allows the housing to dissipate heat from internal electronics, extending component lifespan. |

| Mechanical Strength | Aluminum alloy provides exceptional impact resistance, protecting the meter from physical damage. |

| Environmental Protection | IP65 rating ensures complete dust ingress protection and resistance to low-pressure water jets. |

Bottom Line: A metal enclosure isn’t just about looking "industrial." It directly impacts measurement reliability and long-term maintenance costs.

The Problem with Monochrome LCD Displays

The typical wall mount ultrasonic flow meter ships with a 2-line or 4-line monochrome LCD. While functional in laboratory conditions, these displays create real problems in the field:

1. Poor Visibility

In dimly lit mechanical rooms or under bright sunlight, monochrome LCDs are often impossible to read. Technicians squint, misread values, and make errors.

2. Limited Information Density

A 2-line display can only show one parameter at a time. Want to see flow rate AND total flow AND velocity? Prepare to press buttons repeatedly to scroll through menus.

Deep menu structures with cryptic abbreviations turn simple tasks into frustrating ordeals. This increases training time for new operators and raises the risk of configuration mistakes.

The Color TFT Display Advantage: Three Key Benefits

The SR6100S-II breaks from tradition with a 320×480 pixel backlit Color TFT screen featuring a 10-line display menu. Here’s why it matters:

| Benefit | How the SR6100S-II Delivers |

|---|---|

| High Resolution & Clarity | 320×480 color pixels provide sharp, crisp visuals. Flow rate, velocity, and totals are easy to read from across the room. |

| Multi-Parameter View | The 10-line display shows multiple parameters simultaneously. No more endless button-pressing to find the data you need. |

| User-Friendly Interface | The menu system is designed for intuitive navigation. Clear labels and logical structure reduce training time and operational errors. |

Figure: The SR6100S-II’s high-resolution color display makes data visible even in challenging lighting conditions.

Flexible Sensor Options for Any Application

Beyond the transmitter, the SR6100S-II offers exceptional flexibility in sensor selection:

Clamp-On Transducers (Non-Invasive)

No pipe cutting required – ideal for retrofit projects.

Multiple temperature ranges available:

* TT01: -40°C to +80°C (Standard)

* TT03: -40°C to +130°C (Medium Temperature)

* TT02H: -40°C to +180°C (High Temperature)

Insertion Transducers (For Large Pipes)

- Best for large diameter pipes (DN80 to DN1200) where clamp-on signals may weaken.

Wide Pipe Size Compatibility

The SR6100S-II supports pipe diameters from DN15mm to DN1200mm (approximately 0.5" to 48"), covering everything from small building water lines to large industrial mains.

SR6100S-II: Full Specifications

| Parameter | Specification |

|---|---|

| Display | 320×480 Color TFT LCD with Backlight |

| Menu Lines | 10 lines, user-friendly navigation |

| Enclosure Material | Aluminum Alloy |

| Enclosure Rating | IP65 |

| Power Supply | 10~36VDC / AC90~245V |

| Accuracy | ±1% of measured value |

| Repeatability | 0.2% |

| Flow Velocity Range | ±0.03 m/s to ±12 m/s |

| Pipe Size Range | DN15 to DN1200 |

| Outputs | 4-20mA, Pulse (0-10KHz), Relay, OCT |

| Communication | RS232/RS485 Modbus (Standard); M-BUS or HART (Optional) |

| Data Storage | Optional 32G SD card module |

| Operating Temperature | -20°C to +60°C (Transmitter) |

Watch: SR6100S-II Product Introduction

(Video: See the SR6100S-II’s metal enclosure and color display in action)

Applications

The SR6100S-II is widely used in:

HVAC Systems: Chilled water and hot water monitoring for commercial buildings.

Water Treatment: Intake and discharge flow measurement at treatment plants.

Irrigation: Agricultural water management and canal flow monitoring.

Installation Requirement: The pipe must be completely filled with liquid during operation. Avoid installing immediately adjacent to 90° elbows, valves, or pumps.

Conclusion

Stop settling for fragile plastic enclosures and squinting at tiny monochrome screens.

The SR6100S-II Wall Mount Ultrasonic Flow Meter delivers:

Industrial-Grade Durability: Aluminum alloy enclosure with IP65 protection, EMC shielding, and superior impact resistance.

User-Friendly Operation: 320×480 color TFT display with 10-line menus for clear, at-a-glance data.

Flexible Installation: Clamp-on and insertion sensors covering DN15 to DN1200.

Whether you’re upgrading an aging system or specifying for a new project, the SR6100S-II is built to last.

Ready to Upgrade?

Request a Quote for SR6100S-II — Our engineers will help you select the right sensor configuration for your application.

For full technical details, visit: Ultrasonic Flow Meter Product Range

Published by Shanghai Soaring Instrument Technology Co., Ltd. | December 2025