Looking for a flow measurement solution that doesn’t require cutting into your pipes or shutting down your process? A clamp on ultrasonic flow meter offers non-invasive, highly accurate liquid flow measurement with no moving parts and minimal maintenance—making it the go-to choice for modern industrial applications.

In this guide, I’ll walk you through everything you need to know about clamp on ultrasonic flow meters—from how they work to where they excel, plus expert tips on getting the best performance from your installation.

What is a Clamp On Ultrasonic Flow Meter?

A clamp on ultrasonic flow meter is an external device that measures the flow rate of liquids through a pipe without any contact with the measured fluid. Unlike inline meters that require pipe cutting and process interruption, clamp on meters simply attach to the outside of the pipe using mounting brackets or straps.

These meters use ultrasonic waves that travel through the pipe wall and liquid to calculate flow velocity. The key advantage? Zero pressure drop, zero contamination risk, and installation in minutes rather than hours.

Key Features at a Glance

| Feature | Benefit |

|---|---|

| Non-invasive design | No pipe cutting required |

| No moving parts | Minimal maintenance |

| External mounting | Easy installation |

| No fluid contact | Works with corrosive liquids |

| Bidirectional | Measures forward and reverse flow |

| Wide turndown ratio | Accurate across flow ranges |

How Does a Clamp On Ultrasonic Flow Meter Work?

Understanding the measuring principle helps you get optimal performance from your meter.

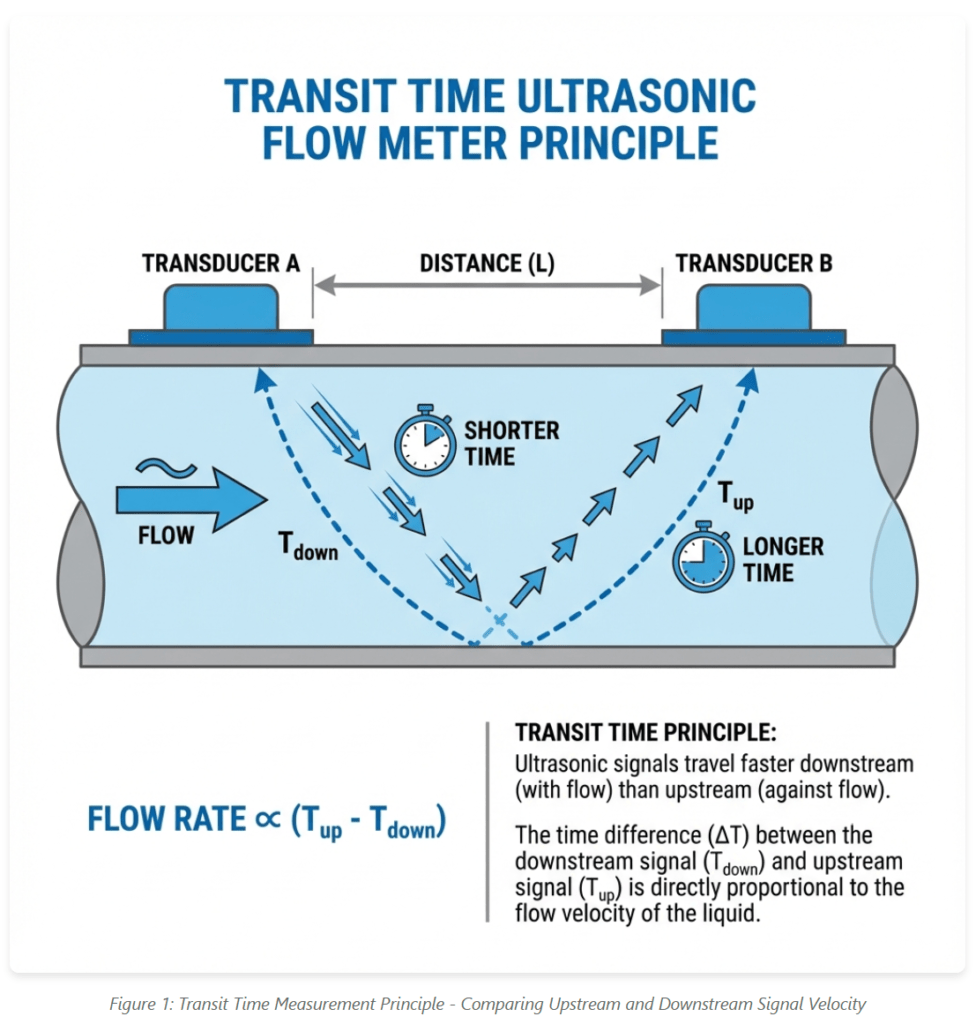

Transit Time Measurement

Transit-Time-Measurement[/caption]

Transit-Time-Measurement[/caption]

Most clamp on ultrasonic flow meters use transit time technology. Here’s how it works:

Two transducers are mounted on the outside of the pipe at a predetermined distance

Each transducer sends ultrasonic signals through the pipe wall and liquid

The meter measures the time difference between upstream and downstream signals

This time differential is directly proportional to the flow velocity

Combined with pipe diameter, the meter calculates volumetric flow rate

The key formula: When liquid flows, the ultrasonic signal traveling downstream moves faster than the signal going upstream. This difference in transit time—typically measured in nanoseconds—tells us exactly how fast the liquid is moving.

Why Transit Time Works So Well

Transit time clamp on meters excel with:

Clean liquids (water, oils, chemicals)

Homogeneous fluids without excessive bubbles

Applications requiring high accuracy (±1% or better)

Bidirectional flow measurement

Pro Tip: For dirty fluids with particles or bubbles, consider a Doppler-type ultrasonic meter instead. For more on the technology comparison, see our guide on how ultrasonic flow meters work.

Advantages of Clamp On Ultrasonic Flow Meters

Why are engineers increasingly choosing clamp on technology? Let me break down the main benefits:

1. No Moving Parts = Minimal Maintenance

Unlike turbine or positive displacement meters, clamp on ultrasonic meters have no internal mechanical components to wear out. This means:

No recurring parts replacement

No calibration drift from wear

Reduced total cost of ownership

Extended service life (15+ years typical)

2. Zero Process Interruption

Installation happens while your process keeps running. No need to:

Drain pipes

Cut into process lines

Schedule extended shutdowns

Worry about contamination

A trained technician can install a clamp on meter in under 30 minutes—compared to hours or days for inline alternatives.

3. Zero Pressure Drop

Because clamp on meters mount externally, there’s nothing inside the pipe to restrict flow. This means:

No energy losses

No pumping costs increase

No flow profile disturbance

Ideal for large-diameter applications

4. Flexibility and Portability

Many clamp on ultrasonic meters offer portable options, perfect for:

Temporary flow surveys

Verification of existing meters

Troubleshooting process issues

Energy audits

For field applications, check out our article on what makes handheld ultrasonic flow meters essential for field measurements.

Where Are Clamp On Ultrasonic Flow Meters Used?

Typical Industrial Installation ofa Clamp On Ultrasonic Flow Meter Typical Industrial Installation of a Clamp On Ultrasonic Flow Meter

The versatility of clamp on technology makes it suitable for a remarkable range of applications:

Water and Wastewater

Municipal water systems and treatment plants rely on clamp on meters for:

Distribution monitoring

Leak detection

Billing verification

Process optimization

Learn more about flow measurement in wastewater treatment.

HVAC and Building Systems

Clamp on meters provide non-invasive flow monitoring for:

Chilled water measurement

Hot water systems

Energy management

BTU calculations

For energy applications, see our guide on how clamp on ultrasonic flow meters measure energy.

Oil and Gas

The industry uses clamp on technology for:

Produced water measurement

Injection monitoring

Custody transfer verification

Pipeline surveys

Chemical Processing

Clamp on meters handle challenging applications including:

Corrosive chemicals

High-purity fluids

Clean-in-place processes

Multi-product lines

For corrosive applications, read what flow meter should you choose for corrosive liquids.

Clamp On vs Inline: Which Should You Choose?

This is one of the most common questions I hear from engineers. Here’s my decision framework:

Choose Clamp On When:

✅ You cannot shut down your process

✅ Pipe cutting is not permitted

✅ You need temporary or portable measurement

✅ Contamination must be avoided

✅ Pressure drop is a concern

✅ Large pipes (>DN200) make inline meters expensive

Choose Inline When:

✅ Maximum accuracy is required (custody transfer)

✅ Pipe conditions are poor (severe scaling, linings)

✅ New installations where pipe is already being modified

✅ Very small pipes (<DN15) where clamp on struggles

For a detailed comparison, see our article on key differences between inline and clamp on ultrasonic flow meters.

Installation Best Practices for Clamp On Meters

Getting accurate measurements depends heavily on proper installation. While the process is non-invasive, you must strictly follow the requirements for straight pipe runs and surface preparation.

Key Requirements:

Straight Run: Typically 10D upstream and 5D downstream.

Surface: Must be clean, rust-free, and smooth.

Coupling: Use generous amounts of acoustic gel.

Need a step-by-step guide?

Read our detailed tutorial: How to Install a Clamp On Ultrasonic Flow Meter: Step-by-Step Guide. It covers V-Method vs Z-Method selection and dealing with old pipes.

Troubleshooting Common Issues

Signal issues are the most common challenge with clamp on meters. If you’re experiencing "No Signal" or unstable readings, it’s usually due to:

Dry coupling gel

Internal pipe lining separation

Incorrect pipe parameters entered

Fix your signal issues now:

Check our Clamp On Ultrasonic Flow Meter Troubleshooting Checklist for quick fixes to the top 5 problems.

Cost Comparison: Clamp On vs Inline

Is clamp on technology worth the investment? Let’s look at the numbers for a typical DN300 (12-inch) water pipe retrofit:

| Cost Factor | Inline Magnetic Meter | Clamp On Ultrasonic Meter |

|---|---|---|

| Device Cost | $2,500 | $2,800 |

| Installation Labor | $1,500 (2 days, 2 people) | $200 (2 hours, 1 person) |

| Heavy Equipment | $800 (Crane/Hoist) | $0 |

| Process Downtime | $5,000+ (Shutdown required) | $0 (Install while running) |

| Total Estimated | $9,800+ | $3,000 |

Result: While the clamp on device might cost slightly more upfront, the total project savings can exceed 60% by eliminating construction and downtime.

Limitations to Be Aware Of

No technology is perfect. Here are the key limitations of clamp on ultrasonic flow meters:

The "Lining Killer"

Critical Warning: If your pipe has an internal lining (cement, rubber, epoxy), there must be a perfect bond between the lining and the pipe wall. Even a microscopic air gap will block the ultrasonic signal completely.

Safe: Bonded Teflon, Epoxy

Risky: Cement, Loose Rubber

Solution: If unsure, request a portable meter demo to verify signal before buying.

Pipe Condition Sensitivity

Heavily scaled, corroded, or lined pipes can attenuate signals, reducing accuracy or preventing measurement altogether.

Temperature Limits

Most standard transducers work from -40°C to +150°C. For higher temperatures, you’ll need special high-temperature transducers.

Accuracy Considerations

While clamp on meters achieve excellent accuracy (typically ±1-2%), inline meters may offer better performance (±0.5%) for critical applications.

For a complete discussion, read our article on real-world limitations of clamp on ultrasonic flow meters.

Small Pipe Applications

One common question: Can clamp on meters work on small pipes?

Yes—but with some considerations. Modern clamp on ultrasonic flow meters can measure pipes as small as DN15 (½ inch), but small pipes present challenges:

Limited mounting space

Higher sensitivity to installation accuracy

Increased signal attenuation

For small pipe applications, choose a meter specifically designed for this purpose. Learn more in our guide: Can clamp on ultrasonic flow meters work effectively on small pipes?

Choosing the Right Clamp On Ultrasonic Flow Meter

When specifying a clamp on meter, consider these key factors:

1. Pipe Size Range

Ensure the meter covers your pipe diameter with appropriate transducers.

2. Accuracy Requirements

Match meter accuracy to your application needs.

3. Output Options

Common outputs include:

4-20mA analog

Pulse/frequency

RS485/Modbus

HART

4. Environmental Rating

Consider IP rating for outdoor or harsh environments.

5. Temperature Range

Verify transducer compatibility with your process temperature.

Conclusion

Clamp on ultrasonic flow meters have revolutionized liquid flow measurement by offering:

Non-invasive installation without process shutdown

No moving parts for minimal maintenance

Zero pressure drop for energy efficiency

Flexibility for temporary or permanent applications

Whether you’re measuring cooling water, tracking chemical usage, or verifying billing meters, clamp on technology delivers accurate, reliable performance across a remarkable range of applications.

Ready to Try It Yourself?

Don’t guess about signal quality. Request a Portable Meter Demo today to see how clamp on technology works on your specific pipes.

Or download our Ultrasonic Flow Meter Selection Guide PDF for detailed technical specs.

Frequently Asked Questions (FAQ)

What is a clamp on ultrasonic flow meter?

A clamp on ultrasonic flow meter is a non-invasive device that measures liquid flow rate by mounting transducers externally on a pipe. It uses ultrasonic waves to measure flow velocity through the pipe wall without requiring pipe cutting or process shutdown. This technology offers zero pressure drop, no moving parts, and minimal maintenance requirements.

How accurate are clamp on ultrasonic flow meters?

Clamp on ultrasonic flow meters typically achieve accuracy of ±1-2% of reading under proper installation conditions. Factors affecting accuracy include pipe condition, straight run requirements, fluid properties, and installation quality. For optimal accuracy, ensure adequate upstream (10-30D) and downstream (5D) straight pipe runs.

Can clamp on flow meters work on small pipes?

Yes, modern clamp on ultrasonic flow meters can measure pipes as small as DN15 (½ inch). However, small pipe applications require specialized high-frequency transducers and more precise installation. Accuracy may be slightly reduced compared to larger pipe applications due to signal attenuation and limited mounting space.

What liquids can be measured with clamp on ultrasonic meters?

Clamp on ultrasonic flow meters work with most clean, homogeneous liquids including:

Water (hot, cold, chilled, cooling)

Oils (hydraulic, lubricating, thermal)

Chemicals (acids, bases, solvents)

Fuels (diesel, gasoline, jet fuel)

Beverages and food-grade liquids

They are not suitable for liquids with high concentrations of bubbles or solid particles—use Doppler-type meters for those applications.

What is the difference between clamp on and inline ultrasonic flow meters?

The main differences are:

Installation: Clamp on mounts externally (no pipe cutting); inline requires pipe modification

Accuracy: Inline typically offers ±0.5% vs ±1-2% for clamp on

Downtime: Clamp on requires zero process interruption; inline needs shutdown

Cost: Clamp on often has lower total installation cost, especially for large pipes

Flexibility: Clamp on can be portable; inline is permanently installed

How long do clamp on ultrasonic flow meters last?

With proper installation and minimal maintenance, clamp on ultrasonic flow meters typically last 15-20+ years. Since they have no moving parts and no fluid contact, there’s minimal wear. The main maintenance is periodic transducer coupling inspection and occasional recalibration verification.

What pipe materials are compatible with clamp on meters?

Clamp on ultrasonic meters work on most common pipe materials:

✅ Carbon steel, stainless steel

✅ Copper, brass

✅ PVC, CPVC, PE, PP, PVDF

✅ Cast iron, ductile iron

⚠️ Concrete or cement-lined pipes may require special transducers

❌ Pipes with severe internal scaling or air gaps in linings

Do clamp on flow meters require special maintenance?

Clamp on ultrasonic flow meters require minimal maintenance:

Check transducer coupling every 6-12 months

Verify signal strength periodically

Recalibrate against reference every 1-2 years (optional)

Replace coupling gel if dried out

Protect from physical damage and extreme temperatures

Related Articles

What Are the Key Applications of Clamp On Ultrasonic BTU Meters?

How to Install a Transit Time Ultrasonic Flow Meter Correctly

Key Takeaways

| Topic | Key Point |

|---|---|

| Definition | Non-invasive flow meter using ultrasonic waves through pipe wall |

| Principle | Transit time measurement between upstream/downstream signals |

| Accuracy | ±1-2% typical; ±1% achievable with optimal installation |

| Pipe Sizes | DN15 to DN5000+ (material dependent) |

| Advantages | No moving parts, zero pressure drop, no process shutdown |

| Best For | Water, oils, chemicals, HVAC, retrofit applications |

| Limitations | Pipe condition sensitive, requires straight runs |

| Lifespan | 15-20+ years with minimal maintenance |

Last updated: December 2025| Shanghai Soaring Instrument Technology Co., Ltd.