Last year, a food processing plant lost $50,000 in product due to inaccurate measurements from an uncalibrated flow meter. Don’t let this happen to you.

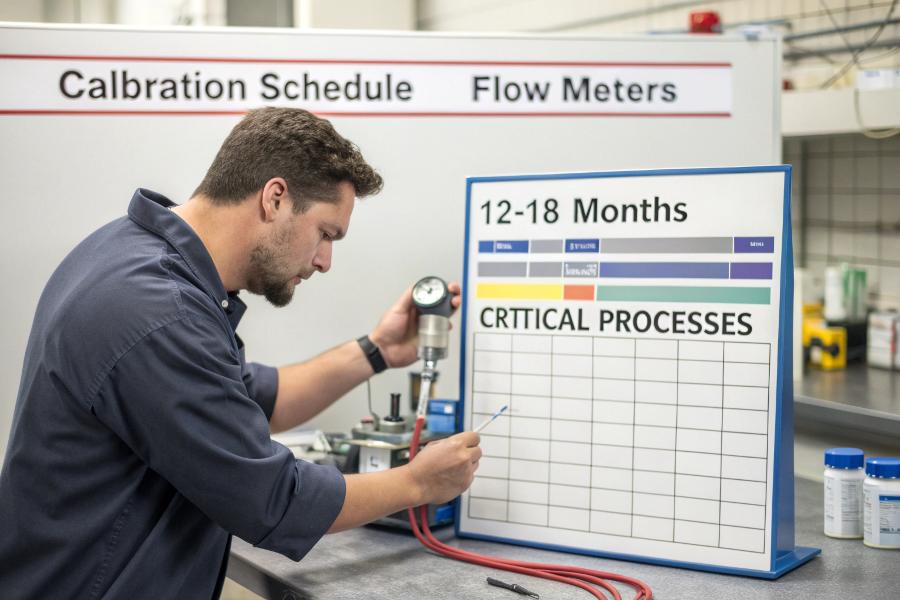

Most flow meters require calibration every 12-18 months, but frequency depends on the application, fluid type, and regulatory requirements. Critical processes may need more frequent calibration.

Flow Meter Calibration Schedule

I’ve seen the consequences of poor calibration firsthand. Let me share what I’ve learned about keeping your measurements accurate and reliable.

Why Is Flow Meter Calibration So Important?

During a recent audit, we discovered a chemical plant was losing 5% of their product daily due to drift in their uncalibrated meters.

Calibration ensures measurement accuracy, maintains compliance with regulations, and optimizes process efficiency. It’s essential for quality control and cost management.

Calibration Importance Factors

Understanding Calibration Basics

Calibration Components

Element Purpose Impact Frequency Zero check1 Baseline Accuracy Monthly Span verification Range accuracy Linearity Quarterly Physical inspection Wear detection Reliability Semi-annual Full calibration2 Complete check Certification Annual Benefits of Regular Calibration

- Maintained accuracy

- Regulatory compliance

- Cost savings

- Quality assurance

What Factors Affect Calibration Frequency?

I helped a petrochemical client develop a customized calibration schedule that saved them 30% on maintenance costs while improving accuracy.

Calibration frequency depends on fluid properties, operating conditions, accuracy requirements, and regulatory standards. Harsh environments often require more frequent calibration.

Key Influencing Factors

Application-Specific Requirements

Factor Impact Level Frequency Adjustment Consideration Process criticality High More frequent Safety Fluid type Medium Based on corrosion Wear Environment Variable Condition-based Stability Regulations Strict As required Compliance

What Signs Indicate Need for Calibration?

A water treatment plant noticed a 15% efficiency drop – a clear sign their meters needed immediate calibration.

Watch for inconsistent readings, unexpected alarms, process inefficiencies, and quality control issues. These are common indicators that calibration is needed.

Signs Requiring Calibration

Recognition of Calibration Needs

Warning Signs Matrix

Indicator Cause Impact Action Reading drift3 Wear/buildup Accuracy loss Verify Process variance4 Calibration shift Quality issues Check Error messages System problems Reliability Diagnose Efficiency drop Measurement error Cost increase Assess

What Are Best Practices for Maintaining Calibration?

I developed a maintenance protocol that helped clients reduce calibration costs by 40% while improving reliability.

Best practices include regular verification checks, documented procedures, trained personnel, and proper environmental controls. Prevention is better than correction.

Maintenance Protocol Elements

Calibration Management

Practice Purpose Frequency Benefit Documentation Tracking Each event History Training Competency Annual Reliability Verification Confirmation Monthly Confidence Environment Stability Continuous Accuracy

What Are the Consequences of Neglecting Calibration?

One manufacturing facility faced $100,000 in regulatory fines due to out-of-calibration meters affecting product quality.

Neglecting calibration can lead to product waste, energy inefficiency, regulatory non-compliance, and safety risks. The costs far exceed regular maintenance.

Impact Assessment

Risk Analysis

Consequence Financial Impact Operational Impact Prevention Inaccuracy High Quality loss Schedule Non-compliance Severe Legal issues Monitor Safety risks Critical Shutdown Maintain Inefficiency Ongoing Cost increase Track

Conclusion

Regular calibration is essential for flow meter accuracy and reliability. Establish a proper maintenance schedule based on your specific needs and conditions.

Need help developing your calibration schedule? Contact our calibration experts for personalized guidance.

Understanding the Zero check is crucial for ensuring accuracy in measurements, making this resource invaluable. ↩

Exploring Full calibration will provide insights into maintaining certification and overall measurement reliability. ↩

Understanding Reading drift can help you maintain accuracy in measurements, ensuring reliable results. ↩

Exploring Process variance will provide insights into maintaining quality control and improving production efficiency. ↩