Many industrial users waste money on magnetic flowmeters only to discover they won’t work with their non-conductive liquids like oils or pure water.

Magnetic flowmeters cannot measure non-conductive liquids such as oils, hydrocarbons, ultra-pure water, and most organic chemicals due to their requirement for fluid conductivity above 5µS/cm.

Non-conductive Liquids and Magnetic Flowmeters

Let me share my experience with magnetic flowmeter applications and limitations.

Which Liquid Cannot Be Measured By The Magnetic Flow Meter?

I often see customers struggling with magnetic flowmeter failures when trying to measure the wrong types of liquids.

Non-conductive liquids that magnetic flowmeters cannot measure include petroleum products, pure water, alcohols, and most hydrocarbon-based chemicals.

Based on my field experience:

Non-Measurable Liquids

Common Examples

Liquid Type Conductivity Why It Won’t Work Alternative Solution Petroleum <1µS/cm Too low conductivity Turbine meter Pure water <1µS/cm Insufficient ions Ultrasonic meter Alcohol <2µS/cm Non-polar molecule Coriolis meter Oils <1µS/cm Non-conductive PD meter - Molecular structure

- Ion content

- Chemical composition

- Electrical properties

Technical Limitations

Operating Principles

- Faraday’s law requirements2

- Conductivity thresholds

- Signal generation

- Measurement accuracy

Application Constraints

- Minimum conductivity needs

- Temperature effects

- Installation requirements

- Maintenance considerations

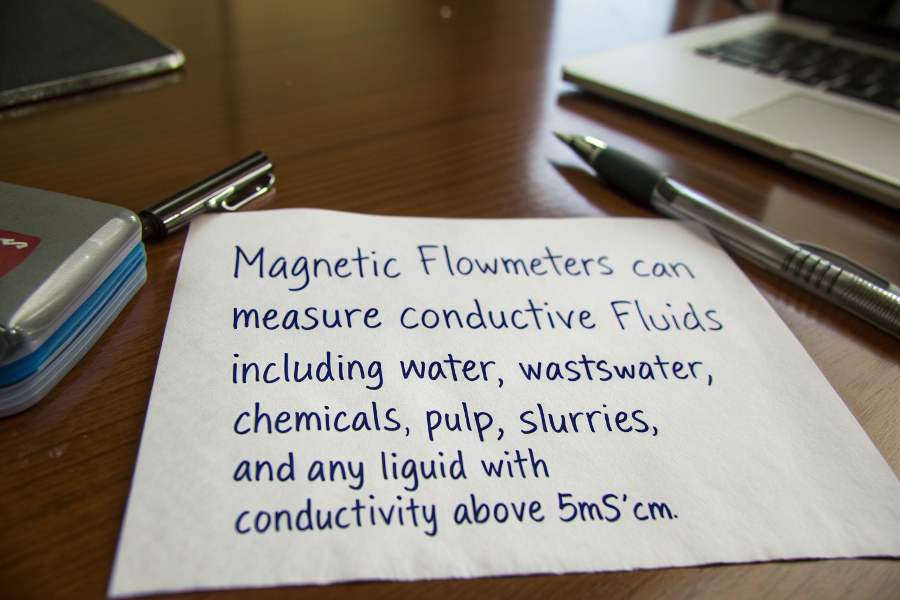

What Type Of Fluids Can Magnetic Flow Meters Measure?

Many operators are unsure about which fluids will work well with magnetic flowmeters.

Magnetic flowmeters can measure conductive fluids including water, wastewater, chemicals, pulp, slurries, and any liquid with conductivity above 5µS/cm.

Fluids Suitable for Magnetic Flowmeters

From my implementation experience:

Suitable Fluids

Common Applications

Fluid Type Typical Conductivity Best Applications Key Benefits Water >50µS/cm Distribution No pressure loss Wastewater >100µS/cm Treatment plants Handles solids Chemicals >20µS/cm Process control Chemical resistant Slurries >50µS/cm Mining Abrasion resistant Performance Factors

- Conductivity levels

- Solid content

- Flow velocity

- Temperature range

Implementation Guidelines

Selection Criteria

- Process requirements

- Fluid properties

- Installation conditions

- Maintenance needs

Operational Considerations

- Grounding requirements

- Liner selection

- Electrode materials

- Signal processing

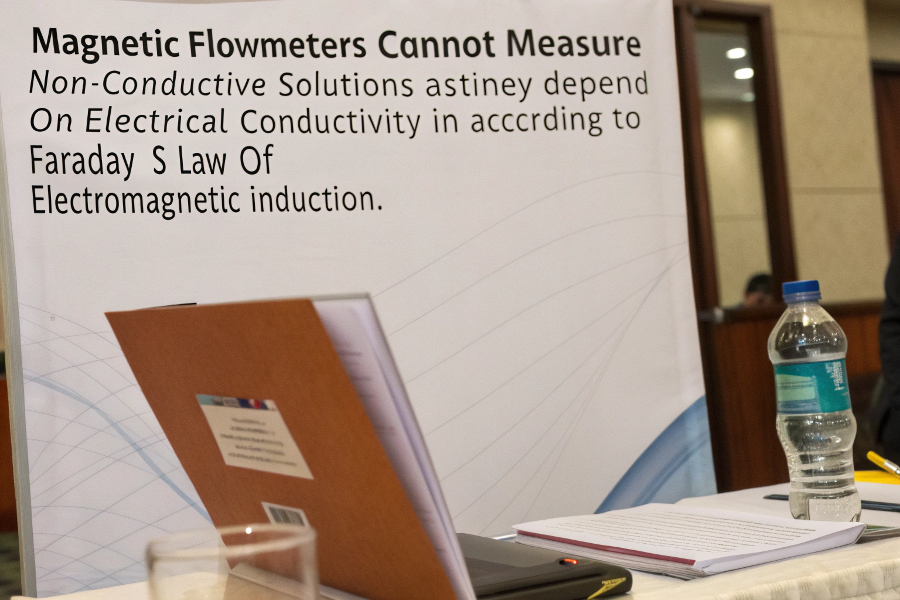

What Type Flow Meter Is Not Applicable For Non-Conductive Liquids?

Understanding which flowmeters won’t work with non-conductive liquids can save time and money in project planning.

Magnetic flowmeters are not applicable for non-conductive liquids as they rely on Faraday’s law of electromagnetic induction, requiring electrical conductivity in the fluid.

Alternative Solutions for Non-conductive Liquids

Drawing from my expertise:

Alternative Solutions

Technology Options

Meter Type Working Principle Advantages Applications Ultrasonic Sound waves Non-invasive Clean liquids Coriolis Mass flow High accuracy All liquids Turbine Mechanical Cost-effective Low viscosity PD Volume displacement High accuracy High viscosity Selection Guidelines

- Fluid properties

- Process conditions

- Accuracy needs

- Budget constraints

Application Considerations

Implementation Factors

- Installation requirements

- Maintenance access

- Environmental conditions

- Performance monitoring

Operational Requirements

- Calibration needs

- Cleaning procedures

- Spare parts

- Technical support

Do Magnetic Flow Meters Measure Viscosity?

Plant operators often ask about additional measurement capabilities of magnetic flowmeters.

No, magnetic flowmeters cannot measure viscosity as they only measure volumetric flow rate based on electromagnetic induction principles.

Based on my experience:

Measurement Capabilities

Parameter Overview

Parameter Can Mag Meter Measure? Alternative Solution Application Flow rate Yes Primary function All conductives Viscosity No Coriolis meter Process control Density No Nuclear/Coriolis Quality control Temperature Indirect RTD/Thermowell Process monitoring Technology Limitations

- Single parameter measurement

- Conductivity dependence

- Operating principles

- Signal processing

Additional Considerations

Multi-Parameter Needs

- Process requirements

- Instrument selection

- Integration options

- Cost implications

Solution Development

- Application analysis

- Technology matching

- Implementation planning

- Performance validation

Conclusion

Magnetic flowmeters are excellent for conductive fluids but completely unsuitable for non-conductive liquids, requiring careful consideration of fluid properties and alternative technologies for successful flow measurement.