Many industrial users face measurement failures with magnetic flow meters due to improper understanding of fluid conductivity requirements.

Electromagnetic flow meters require a minimum fluid conductivity of 5 μS/cm for accurate measurement, with optimal performance typically achieved above 20 μS/cm.

Conductive Fluids for Flow Meters

I’ve encountered numerous cases where proper understanding of conductivity requirements could have prevented costly measurement errors.

What Is The Conductivity Requirement For Magnetic Flow Meter?

Understanding conductivity requirements is crucial for magnetic flow meter selection and operation.

Most magnetic flow meters require a minimum conductivity of 5 μS/cm, though some specialized models can measure down to 1 μS/cm with reduced accuracy.

Magnetic Flow Meter Conductivity Requirements

From my extensive field experience:

Conductivity Requirements

-

Minimum Conductivity Levels

Fluid Type Min. Conductivity Typical Application Notes Process Water 5 μS/cm General Industry Standard Demineralized 1-5 μS/cm Power Plants Special units Slurries >20 μS/cm Mining High reliability Chemical >100 μS/cm Chemical Industry Best accuracy -

Impact Factors

- Temperature effects

- Pressure influence

- Chemical composition

- Fluid homogeneity

Performance Optimization

-

Installation Guidelines

- Proper grounding

- Electrode positioning

- Cable shielding

- Environmental protection

-

Maintenance Requirements

- Regular calibration

- Electrode cleaning

- Conductivity monitoring

- Signal verification

What Causes Errors In A Magnetic Flow Meter?

Measurement errors can significantly impact process control and product quality.

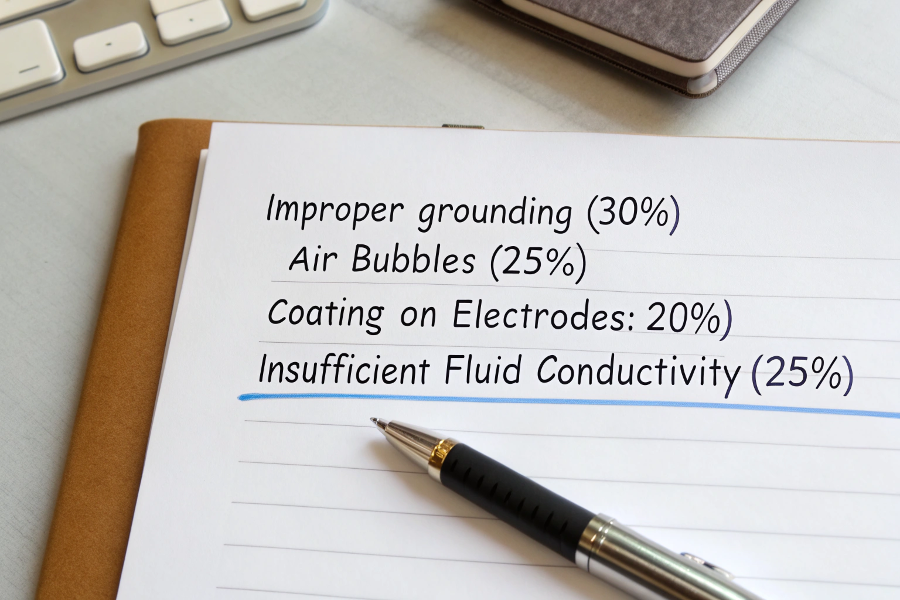

Common causes of magnetic flow meter errors include improper grounding, air bubbles, coating on electrodes, and insufficient fluid conductivity.

Common Error Sources in Magnetic Flow Meters

Based on my troubleshooting experience:

Error Sources

-

Common Problems

Error Source Impact Solution Prevention Poor Grounding Signal noise Improve grounds Regular checks Air Bubbles Erratic readings Install air vents Proper installation Coating Signal loss Regular cleaning Chemical compatibility Low Conductivity No reading Fluid treatment Proper selection -

Installation Issues

- Incorrect orientation

- Insufficient straight runs

- EMI interference

- Vibration effects

Troubleshooting Process

-

Systematic Approach

- Signal verification

- Physical inspection

- Environmental assessment

- Documentation review

-

Corrective Actions

- Cleaning procedures

- Calibration methods

- Parameter adjustment

- Hardware updates

How Accurate Is The Electromagnetic Flowmeter?

Accuracy specifications often confuse users when selecting the right flow meter.

Modern electromagnetic flow meters typically achieve accuracies of ±0.2% to ±0.5% of reading, making them one of the most accurate flow measurement technologies.

Electromagnetic Flow Meter Accuracy Specifications

Drawing from my measurement expertise:

Accuracy Analysis

-

Performance Factors

Accuracy Class Typical Use Cost Impact Requirements ±0.2% Custody Transfer Highest Strict conditions ±0.3% Process Control Medium Good conditions ±0.5% General Purpose Standard Normal conditions >±0.5% Basic Monitoring Economy Basic conditions -

Influencing Factors

- Flow profile

- Installation quality

- Maintenance condition

- Environmental factors

Optimization Methods

-

Installation Requirements

- Proper positioning

- Flow conditioning

- Environmental protection

- Signal optimization

-

Maintenance Practices

- Regular calibration

- Performance verification

- Preventive maintenance

- Documentation

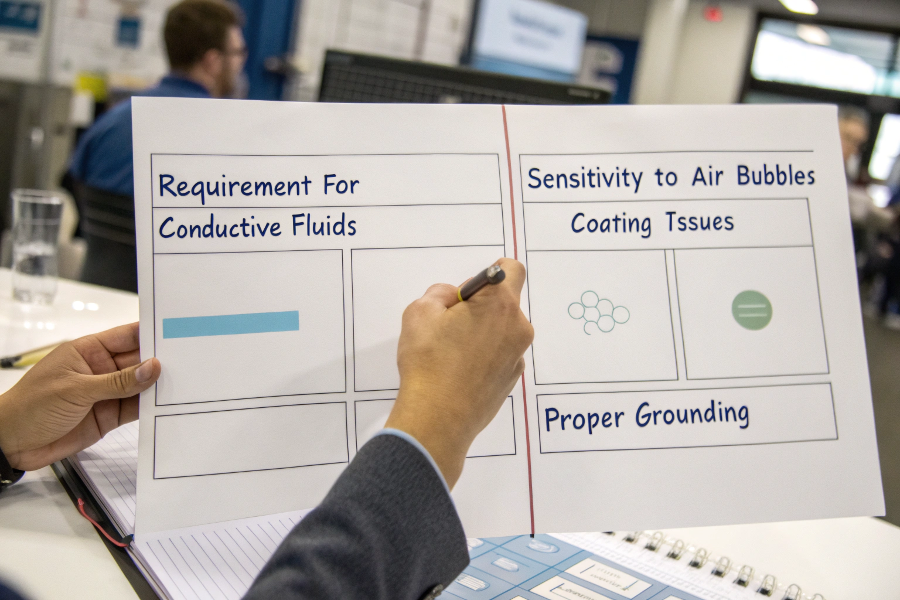

What Are The Limitations Of An Electromagnetic Flow Meter?

Understanding limitations helps prevent application mistakes and ensures reliable measurements.

Key limitations include the requirement for conductive fluids, sensitivity to air bubbles, coating issues, and the need for proper grounding.

Electromagnetic Flow Meter Limitations

From my application experience:

Limitation Analysis

-

Technical Constraints

Limitation Impact Workaround Alternative Conductivity No measurement Fluid treatment Different technology Air Bubbles Errors Air elimination Alternative location Coating Signal loss Special electrodes Different material Cost Budget issues Cost-benefit analysis Simpler technology -

Application Constraints

- Installation space

- Power requirements

- Maintenance access

- Environmental conditions

Solution Strategies

-

Design Considerations

- Technology selection

- Installation planning

- Maintenance requirements

- Cost optimization

-

Alternative Options

- Different technologies

- Hybrid solutions

- Modified installations

- Special configurations

Conclusion

Understanding fluid conductivity requirements and potential error sources is crucial for successful magnetic flow meter application, with proper installation and maintenance being key to achieving specified accuracy levels.