Factory teams often face challenges when installing vortex meters, leading to inaccurate measurements and unnecessary downtime. Proper installation makes all the difference.

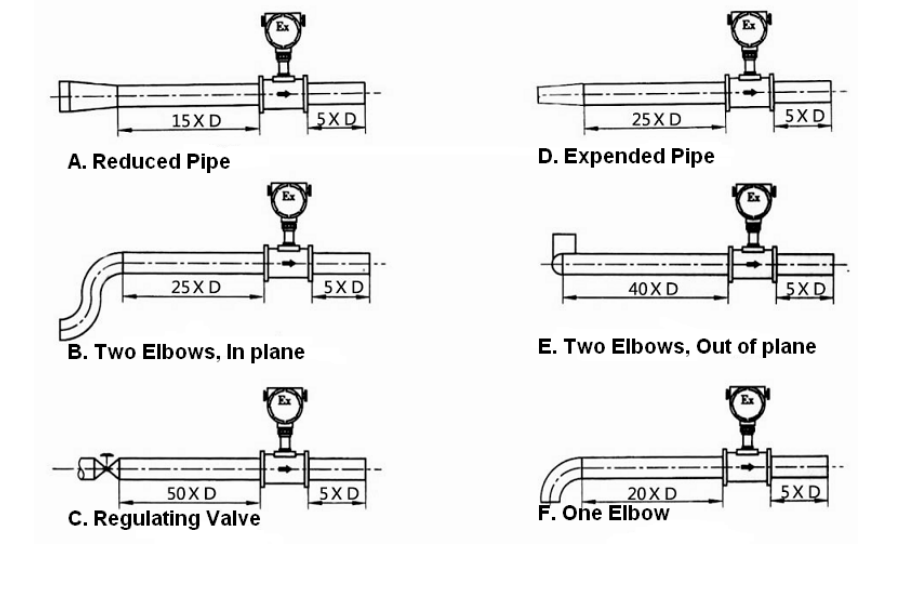

Vortex flow meters require 15 pipe diameters (15D) upstream and 5D downstream straight piping, proper orientation based on fluid type, adequate supports to minimize vibration, and environmental protection from extreme conditions. The minimum distance ensures fully developed flow profile for accurate measurement.

Proper Installation Example

Understanding installation standards prevents 90% of vortex meter performance issues before they occur.

What Are the Requirements for a Vortex Flow Meter?

Five critical installation prerequisites:

Installation Checklist Table

| Requirement | Specification | Reason |

|---|---|---|

| Pipe Straightness | 15D upstream, 5D downstream | Flow profile development |

| Orientation | Horizontal for gases, vertical upwards for liquids | Air bubble/particle elimination |

| Support | Rigid mounting ±1mm alignment | Vibration reduction |

| Environment | -20°C to 60°C ambient | Electronics protection |

| Access | Sufficient service space | Maintenance clearance |

Fluid-Specific Considerations

Steam Applications

- Install condensate pots

- Use thermal expansion joints

- Include pipe anchors

Gas Services

- Position downstream of regulators

- Avoid pulsation sources

- Consider density compensation

Liquid Processes

- Keep always full in vertical pipes

- Eliminate air pockets

- Install sediment filters

Fluid-Specific Requirements

Common Mistakes to Avoid

- Ignoring manufacturer’s minimum straight-run

- Mounting near pumps/compressors

- Using flexible hose connections

- Installing in pulsating flow conditions

- Omitting grounding provisions

How To Install A Vortex Flow Meter?

Installation errors can significantly impact measurement accuracy and meter longevity.

Proper installation involves careful orientation alignment, gasket selection, bolt torquing sequence, and ensuring the flow arrow matches process direction.

Installation-Steps

Based on my field experience:

Installation Process

Pre-Installation Steps

Task Purpose Key Points Site Preparation Ensure access Clean work area Pipe Inspection Verify condition Check alignment Material Check Confirm components Verify gaskets Tool Preparation Proper assembly Calibrated tools Installation Sequence

- Flow direction verification

- Orientation alignment

- Gasket placement

- Bolt installation

- Torque application

- Electronic connection

Quality Checks

- Post-Installation Verification

- Alignment check

- Leak testing

- Signal verification

- Zero calibration

- Documentation

Installation Guidelines

Mounting Considerations

Aspect Requirement Reason Orientation Horizontal preferred Better accuracy Support Independent mounting Reduce stress Access Maintenance clearance Easy service Protection Environmental shield Weather protection Safety Requirements

- Pressure relief provisions

- Isolation valves

- Grounding connections

- Safety barriers

Maintenance Planning

Access Requirements

- Calibration points

- Display visibility

- Service clearance

- Tool accessibility

Documentation Needs

- Installation records

- Calibration certificates

- Maintenance schedules

- Operating procedures

What Are The Requirements For A Vortex Flow Meter?

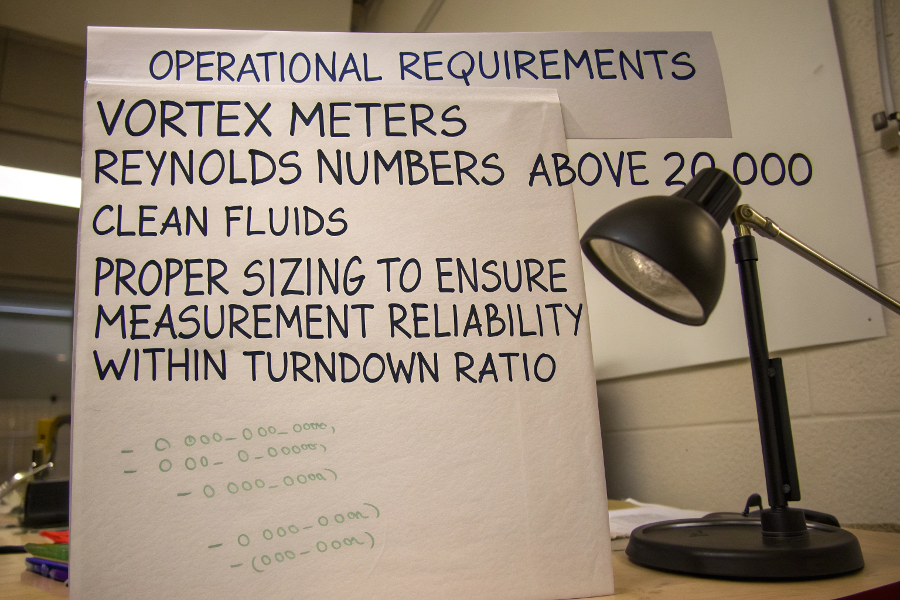

Understanding operational requirements ensures reliable measurement and extended meter life.

Vortex meters need Reynolds numbers above 20,000, clean fluids, and proper sizing to ensure measurement reliability within their specified turndown ratio.

Vortex Flow Meter Requirements

Vortex Flow Meter Requirements

Drawing from my technical knowledge:

Operational Requirements

Process Conditions

Parameter Requirement Impact Reynolds Number1 >20,000 Accuracy Flow Profile Fully developed Stability Fluid Quality Clean Reliability Pressure Drop2 Acceptable Energy cost Physical Requirements

- Proper pipe size

- Material compatibility

- Temperature limits

- Pressure ratings

System Integration

- Technical Considerations

- Power supply requirements

- Signal output compatibility

- Communication protocols

- Environmental protection

Conclusion

Successful vortex flow meter installation requires careful attention to straight run requirements, proper orientation, and installation best practices, ensuring reliable measurement and long-term performance.