Selecting the wrong flow meter for natural gas can lead to significant measurement errors and costly operational inefficiencies.

For natural gas measurement, vortex flow meters offer excellent accuracy and reliability, especially in high-pressure applications, with typical accuracies of ±1% of reading and high turndown ratios.

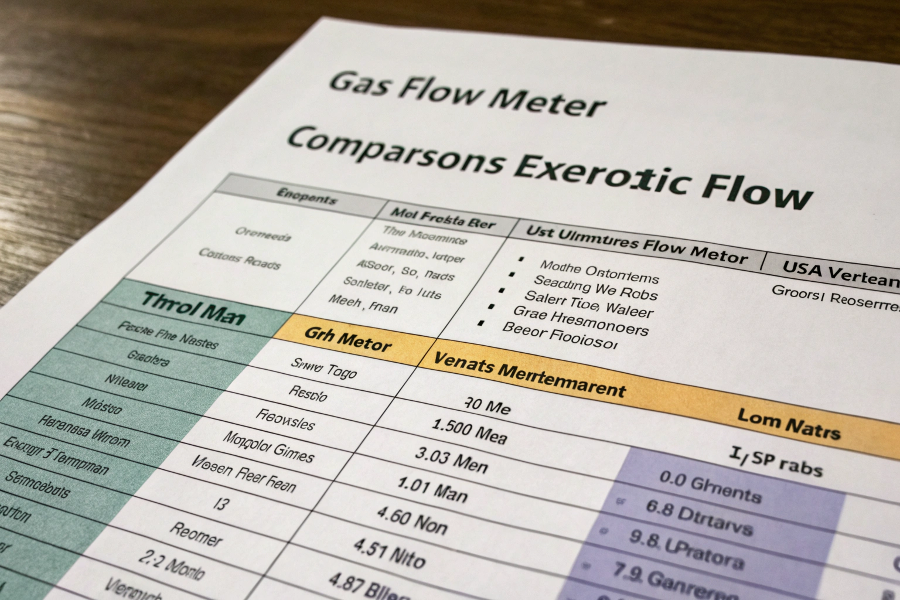

Flow Meter Types for Natural Gas

Let me share my experience helping customers choose the right flow meter for their natural gas applications.

What Is The Best Flow Meter For Gas?

Choosing the right gas flow meter can be overwhelming with so many options available.

For gas flow measurement, thermal mass, ultrasonic, and vortex flow meters are top choices, with vortex meters excelling in high-pressure applications and thermal mass for low-flow scenarios.

Gas Flow Meter Technology Comparison

From my field experience:

Flow Meter Technology Comparison

Popular Gas Flow Technologies

Technology Strengths Limitations Vortex High accuracy, no moving parts Minimum flow requirement Thermal Mass Direct mass flow, low flow Limited to clean gases Ultrasonic Non-intrusive, bi-directional Higher initial cost Coriolis Highest accuracy, multi-variable Size/cost limitations Application Considerations

- Operating pressure range

- Flow rate requirements

- Gas composition

- Installation constraints

Selection Criteria

Performance Requirements

- Accuracy needs

- Turndown ratio

- Response time

- Long-term stability

Environmental Factors

- Temperature variations

- Pressure fluctuations

- Vibration conditions

- Weather exposure

When To Use A Vortex Flowmeter?

Understanding the optimal conditions for vortex meters ensures successful applications.

Vortex flowmeters are ideal for natural gas when Reynolds numbers exceed 20,000, pressures are stable, and straight run requirements can be met.

Vortex Meter Application Guide

Based on my installation experience:

Application Guidelines

Ideal Conditions

Parameter Requirement Reason Reynolds Number >20,000 Strong vortex formation Straight Run 15-30D Flow profile development Pressure Stable Consistent readings Gas Quality Clean Prevent buildup Process Considerations

- Flow velocity range

- Pressure drop allowance

- Temperature limits

- Material compatibility

Installation Requirements

Physical Setup

- Proper orientation

- Support structure

- Access for maintenance

- Insulation needs

Safety Considerations

- Pressure ratings

- Leak prevention

- Explosion protection

- Emergency shutdown

How Do You Measure Natural Gas Flow?

Accurate natural gas measurement requires careful attention to multiple factors.

Natural gas flow measurement typically involves using vortex, ultrasonic, or thermal mass meters, combined with pressure and temperature compensation for mass flow calculation.

Here’s my practical approach:

Measurement System Components

Primary Elements

Component Function Importance Flow Meter Flow rate measurement Primary measurement Pressure sensor Pressure compensation Mass flow calculation Temperature sensor Temperature compensation Density correction Flow computer Data processing System integration System Requirements

- Gas composition analysis

- Pressure regulation

- Temperature monitoring

- Flow conditioning

Measurement Considerations

Operating Parameters

- Flow range

- Pressure variations

- Temperature changes

- Gas quality

Calculation Methods

- Standard conditions

- Compressibility factors

- Energy content

- Mass flow conversion

Can Ultrasonic Flow Meters Be Used For Gas?

Many industries are shifting towards ultrasonic technology for gas measurement.

Yes, ultrasonic flow meters can effectively measure gas flow, offering advantages like non-intrusive measurement, no pressure drop, and bi-directional capability.

From my ultrasonic meter implementation experience:

Ultrasonic Technology Applications

Gas Measurement Capabilities

Feature Benefit Application Non-intrusive No pressure loss High-pressure gas No moving parts Low maintenance Continuous flow Wide turndown Flexible operation Variable flow Bi-directional Flow direction Distribution systems Installation Considerations

- Transducer positioning

- Signal strength

- Gas composition

- Flow profile

Performance Factors

Operating Conditions

- Gas density

- Sound velocity

- Flow profile

- Signal quality

System Requirements

- Power supply

- Signal processing

- Communication

- Maintenance access

Conclusion

For natural gas measurement, vortex flow meters offer an excellent balance of accuracy, reliability, and cost-effectiveness, particularly when properly sized and installed with adequate straight runs.