Tank level measurement errors can lead to serious inventory discrepancies and safety issues.

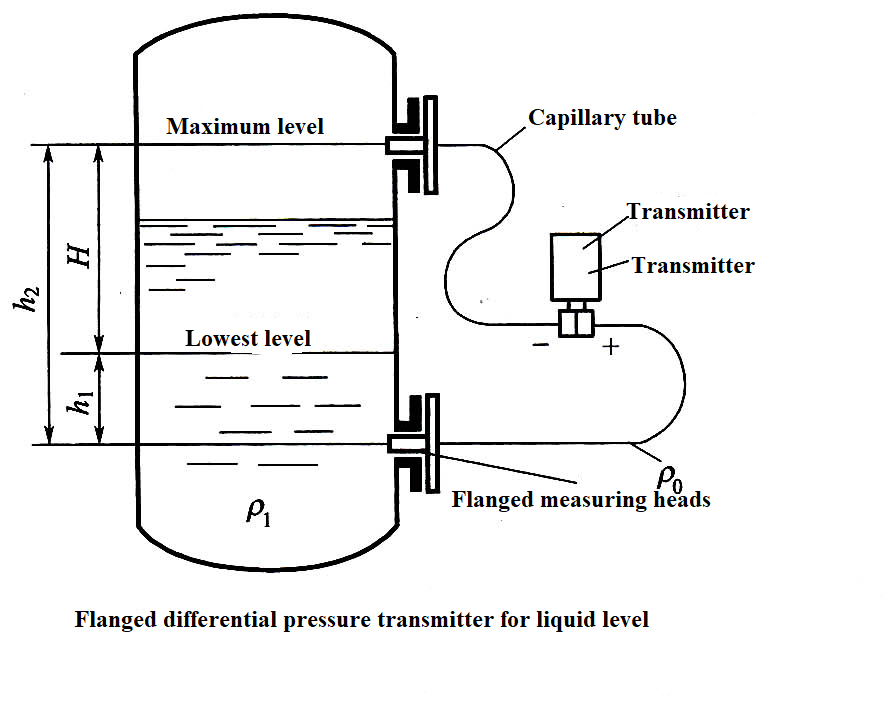

A differential pressure transmitter measures tank level by comparing the pressure at the tank bottom (caused by liquid height) to a reference pressure, typically atmospheric pressure for open tanks.

DP Tank Level Measurement System

Let me share our experience in implementing DP level measurement solutions across various industries.

How To Measure Tank Level Using DP Transmitter?

Improper installation of DP level measurement systems often results in unreliable readings.

To measure tank level using a DP transmitter, install the transmitter below the tank’s lowest measurement point, connect impulse lines properly, and configure the transmitter based on fluid density.

DP Level Installation Guide

From our field experience:

Installation Requirements

Key Components

Component Function Considerations DP Transmitter Level measurement Mounting location Impulse Lines Pressure transfer Proper slope Isolation Valves Maintenance access Type selection Seal Systems Process isolation Material compatibility Installation Guidelines

- Transmitter location

- Impulse line routing

- Reference leg setup

- Calibration access

Configuration Steps

Setup Parameters

- Zero point setting

- Span calculation

- Density compensation

- Temperature effects

Commissioning

- Air purging

- Zero verification

- Range checking

- Documentation

How Do You Measure The Level Of A Tank With Pressure?

Understanding pressure-based level measurement principles is crucial for accurate readings.

Tank level measurement with pressure involves converting the hydrostatic pressure of the liquid column (P = ρgh) into a level reading, where pressure increases linearly with liquid height.

Pressure-Based Level Measurement

Based on our technical expertise:

Measurement Principles

Physical Factors

Factor Impact Consideration Liquid Density Direct effect Temperature compensation Tank Height Range setting Installation limits Pressure Units Conversion Local standards Temperature Density changes Compensation needed Application Considerations

- Open vs. closed tanks

- Process conditions

- Environmental factors

- Maintenance access

System Implementation

Design Requirements

- Accuracy needs

- Range calculation

- Material selection

- Safety considerations

Performance Optimization

- Regular calibration

- Temperature compensation

- Density updates

- Zero checking

What Is A Differential Pressure Manometer For Measuring Liquid Level?

Many users need clarification about different types of level measurement devices.

A differential pressure manometer for liquid level measurement is a device that compares the pressure at the bottom of a tank with a reference pressure to determine liquid height.

DP Manometer Types

Drawing from our product knowledge:

Manometer Types

Common Configurations

Type Operation Application U-Tube Visual comparison Simple systems Electronic Digital output Modern control Smart Advanced features Complex processes Sealed Reference leg Closed tanks Selection Criteria

- Measurement range

- Accuracy requirements

- Process conditions

- Installation limits

Application Considerations

Implementation Factors

- Mounting options

- Signal output

- Maintenance needs

- Calibration methods

Operating Parameters

- Temperature limits

- Pressure range

- Material compatibility

- Environmental protection

What Is The Differential Pressure In A Tank?

Understanding differential pressure concepts is essential for proper level measurement.

Differential pressure in a tank is the pressure difference between two points, typically between the bottom of the tank (hydrostatic pressure) and the top (vapor space or atmospheric pressure).

Tank Differential Pressure Concept

Based on our practical experience:

Pressure Relationships

Key Parameters

Parameter Description Impact Hydrostatic Liquid column Direct measurement Vapor Space Top pressure Reference point Net DP Measurement value Level calculation Static Pressure System pressure Compensation Influencing Factors

- Fluid properties

- Tank conditions

- Environmental effects

- Process changes

Measurement Applications

System Requirements

- Accuracy needs

- Range considerations

- Safety factors

- Maintenance access

Implementation Steps

- Installation planning

- Configuration setup

- Performance validation

- Regular maintenance

Conclusion

Successful tank level measurement using DP transmitters requires proper understanding of principles, careful installation, regular maintenance, and consideration of process conditions.