Choosing the wrong type of pressure transmitter can lead to costly measurement errors and system failures.

Differential pressure transmitters come in various types including capacitive, piezoresistive, strain gauge, and resonant wire technology, each suited for specific applications and pressure ranges.

Types of DP Transmitters

Let me explain the key differences based on our extensive experience with various pressure measurement applications.

What Are the Four Types of Pressure Transmitters?

Many engineers struggle to choose between different pressure transmitter technologies.

The main pressure transmitter types are absolute pressure, gauge pressure, differential pressure, and sealed gauge pressure transmitters.

Pressure Transmitter Categories

From my years of working with various pressure measurement applications:

Pressure Transmitter Classifications

Type Comparison

Type Reference Application Absolute Perfect vacuum Process vacuum Gauge Atmospheric Open vessels Differential Two points Flow/Level Sealed Fixed reference High temperature Selection Factors

- Process conditions

- Environmental requirements

- Accuracy needs

- Installation constraints

Application Considerations

Industry Requirements

- Chemical processing

- Oil and gas

- Water treatment

- Power generation

Operating Conditions

- Temperature range

- Pressure limits

- Media compatibility

- Environmental protection

How to Select Differential Pressure Transmitter Range?

Improper range selection often results in poor measurement accuracy.

Select a DP transmitter range by determining the maximum expected differential pressure, then choose a range that places normal operation at 40-70% of the span.

DP Range Selection Guide

Based on our sizing experience:

Range Selection Process

Sizing Considerations

Factor Consideration Impact Static Pressure System pressure Range limits Turn Down Rangeability Accuracy Overrange Protection Safety margin Resolution Precision Control quality Application Requirements

- Process variations

- Control needs

- Safety margins

- Future flexibility

Performance Optimization

Range Factors

- Normal operating point

- Maximum conditions

- Minimum requirements

- Turndown ratio

Documentation Needs

- Process conditions

- Sizing calculations

- Range settings

- Calibration data

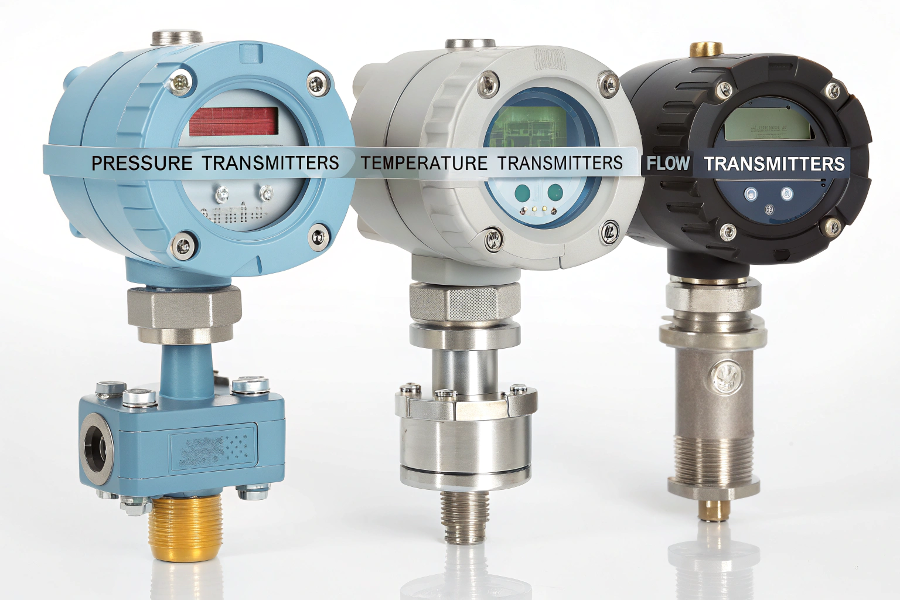

What Are the Three Types of Transmitters?

Understanding transmitter categories helps in proper selection.

The three main transmitter types are pressure transmitters, temperature transmitters, and flow transmitters, each using different sensing principles.

Transmitter Categories Overview

Drawing from our product expertise:

Transmitter Technologies

Basic Categories

Type Principle Applications Pressure Force sensing Process pressure Temperature Heat detection Process temp Flow Various methods Flow measurement Technology Features

- Sensing elements

- Output signals

- Accuracy levels

- Response times

Selection Guidelines

Application Requirements

- Process parameters

- Environmental conditions

- Accuracy needs

- Installation limits

Performance Factors

- Response time

- Stability

- Reliability

- Maintenance needs

What is a DP Type Transmitter?

Many users need clarification about DP transmitter functionality.

A DP transmitter measures the pressure difference between two points, converting this differential into an electronic signal for monitoring flow, level, or pressure drop.

DP Transmitter Operation

Based on our technical knowledge:

Operating Principles

Measurement Methods

Method Operation Application Capacitive Diaphragm movement General purpose Piezo Crystal effect High pressure Strain Material stress Robust needs Resonant Frequency change High accuracy Signal Processing

- Pressure sensing

- Signal conversion

- Output scaling

- Digital communication

Application Areas

Common Uses

- Flow measurement

- Level monitoring

- Filter monitoring

- Pressure control

Special Applications

- Interface level

- Density measurement

- Height measurement

- Pressure drop

Conclusion

Selecting the right DP transmitter type requires understanding various technologies, proper range selection, and matching transmitter capabilities to your specific application requirements.