Many plant operators struggle with accurate and reliable level measurement in their tanks.

A DP transmitter measures liquid level by detecting the hydrostatic pressure created by the liquid column height, converting this pressure difference into a level measurement.

DP Level Measurement Basics

Let me share my expertise in implementing DP level measurement solutions.

What is a Differential Pressure Transmitter Used for Level Measurement?

The concept of using pressure to measure level often confuses first-time users.

DP transmitters measure level by comparing the pressure at the bottom of a tank with either atmospheric pressure or the pressure in the tank’s vapor space.

DP Level Measurement Setup

From my experience with numerous installations:

Measurement Methods

Tank Types and Setups

Tank Type Method Key Considerations Open Tank Referenced to atmosphere Simple setup Closed Tank Wet leg reference Maintenance needs Pressurized Tank Dry leg reference Pressure effects Interface Level Density difference Media properties Application Factors

- Tank dimensions

- Process conditions

- Media properties

- Environmental conditions

System Components

Essential Elements

- Sensing lines

- Isolation valves

- Air/gas traps

- Seal systems

Supporting Equipment

- Mounting brackets

- Protection devices

- Calibration ports

- Documentation systems

How to Use a DP Transmitter for Level Measurement?

Setting up a DP level measurement system requires careful planning.

Install the transmitter below the tank’s lowest measuring point, connect appropriate impulse lines, and calibrate the system based on specific gravity and tank dimensions.

DP Level Installation Guide

Based on our implementation experience:

Installation Steps

Setup Process

Step Action Purpose Location Mount below tank Reference point Connections Install impulse lines Pressure transfer Calibration Set zero and span Measurement range Verification Test functionality Accuracy check Critical Considerations

- Temperature effects

- Vibration isolation

- Accessibility needs

- Maintenance requirements

System Configuration

Programming Parameters

- Zero point setting

- Span adjustment

- Density compensation

- Temperature correction

Documentation Requirements

- Calibration records

- Setup parameters

- Maintenance schedules

- Testing procedures

How to Calculate Differential Pressure for Level Measurement?

Understanding the mathematics behind level measurement helps ensure accurate setup.

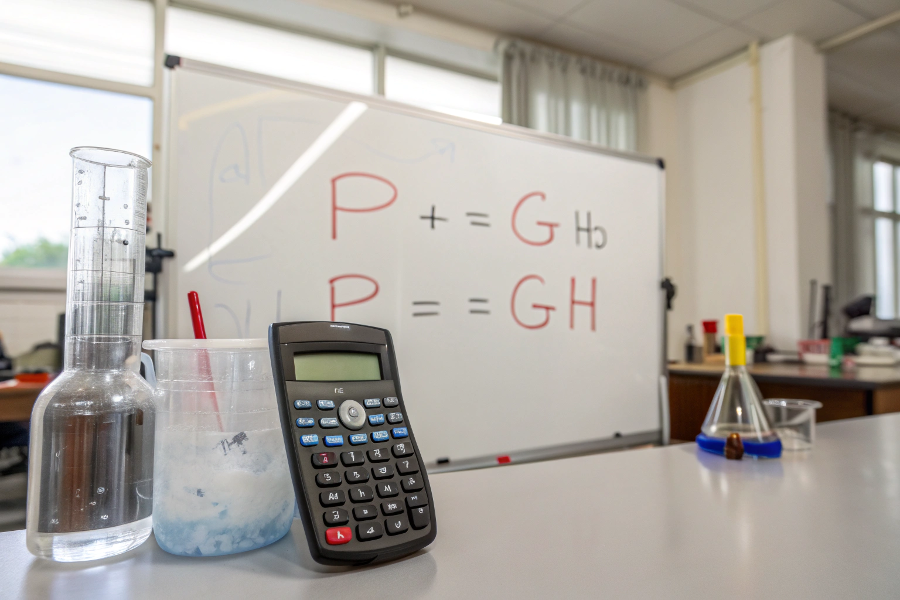

Calculate differential pressure using the formula P = ρgh, where ρ is fluid density, g is gravitational acceleration, and h is liquid height.

DP Level Calculation Diagram

Drawing from our engineering expertise:

Calculation Methods

Basic Formulas

Parameter Formula Units Pressure P = ρgh Pascal Level h = P/ρg Meters Density ρ = P/gh kg/m³ Interface h = ΔP/(ρ1-ρ2)g Meters Correction Factors

- Temperature effects

- Vapor pressure

- Static pressure

- Media density changes

Practical Application

Measurement Considerations

- Tank geometry

- Reference conditions

- Environmental impacts

- Process variations

Calibration Requirements

- Zero adjustment

- Span setting

- Range verification

- Accuracy confirmation

How Do Differential Pressure Transmitters Measure Level by Inference?

Understanding the indirect nature of DP level measurement is crucial.

DP transmitters infer level by measuring the hydrostatic pressure created by the liquid column, using known fluid properties and tank dimensions.

DP Level Inference Method

DP Level Inference Method

Based on our field experience:

Measurement Principles

Key Factors

Factor Impact Consideration Fluid density Direct effect Temperature variation Tank height Range setting Installation limits Pressure changes Zero shift Compensation needs Media properties Accuracy Calibration requirements Environmental Effects

- Temperature changes

- Atmospheric pressure

- Vapor pressure

- Tank conditions

Performance Optimization

Accuracy Improvements

- Regular calibration

- Temperature compensation

- Density updates

- Zero verification

Maintenance Requirements

- Line cleaning

- Seal inspection

- Calibration checks

- Documentation updates

Conclusion

Successful DP level measurement depends on proper installation, accurate calculations, and regular maintenance to ensure reliable and precise level monitoring in your process tanks.