Many engineers struggle with accurate flow measurement in small-diameter pipes, questioning if clamp-on technology is suitable.

Clamp-on ultrasonic flow meters can work on small pipes (typically down to 15mm), but require specific transducer designs and careful installation to maintain accuracy.

Small Pipe Flow Measurement

I’ve helped numerous clients optimize their small pipe measurements, and here’s what I’ve learned.

What are the Disadvantages of Clamp-On Ultrasonic Flow Meters on Small Pipes?

Engineers frequently encounter challenges when applying clamp-on meters to small diameter pipes.

Small pipe applications face increased signal attenuation, limited mounting space, and higher sensitivity to installation conditions, potentially affecting measurement accuracy.

From my field experience:

Technical Challenges

Signal Issues

Challenge Impact Solution Signal strength Weak readings Enhanced transducers Path length Signal loss Optimized frequency Wall thickness Attenuation Material selection Installation space Limited access Compact design Installation Factors

- Limited mounting area

- Critical alignment needs

- Surface preparation importance

- Temperature effects

Performance Limitations

Accuracy Concerns

- Flow profile sensitivity

- Reynolds number effects

- Velocity limitations

- Signal-to-noise ratio

Application Constraints

- Minimum pipe size limits

- Material compatibility

- Flow condition requirements

- Environmental factors

What is the Difference Between Inline and Clamp-On Ultrasonic Flow Meters for Small Pipes?

Plant operators often need to choose between inline and clamp-on solutions for small pipe applications.

For small pipes, inline meters offer better accuracy but require pipe modifications, while clamp-on meters provide non-invasive installation but may have lower accuracy.

Based on my system design experience:

Installation Comparison

Mounting Requirements

Aspect Inline Clamp-on Installation Pipe cutting External mount Downtime Required None needed Space needs Fixed length Minimal space Maintenance Internal access External only Application Considerations

- Process interruption

- Installation costs

- Maintenance access

- Calibration requirements

Performance Analysis

Measurement Capabilities

- Accuracy levels

- Repeatability

- Signal stability

- Flow range

Operational Factors

- Pressure drop

- Maintenance needs

- Long-term stability

- Cost considerations

How Accurate is the Clamp-On Ultrasonic Flow Meter on Small Pipes?

Users often question the reliability of clamp-on meters for small pipe applications.

On small pipes, clamp-on ultrasonic flow meters typically achieve accuracy of ±2-3% of reading, provided proper installation and optimal conditions are maintained.

Accuracy Factors in Small Pipes

Drawing from my measurement expertise:

Accuracy Factors

Critical Parameters

Factor Impact Optimization Installation Signal quality Proper setup Flow profile Measurement accuracy Straight run Fluid properties Signal transmission Parameter setup Pipe condition Signal strength Surface prep Performance Optimization

- Calibration procedures

- Signal validation

- Parameter adjustment

- Environmental protection

Measurement Considerations

Application Factors

- Flow velocity range

- Temperature effects

- Pressure conditions

- Fluid properties

Installation Requirements

- Mounting location

- Surface preparation

- Alignment precision

- Environmental protection

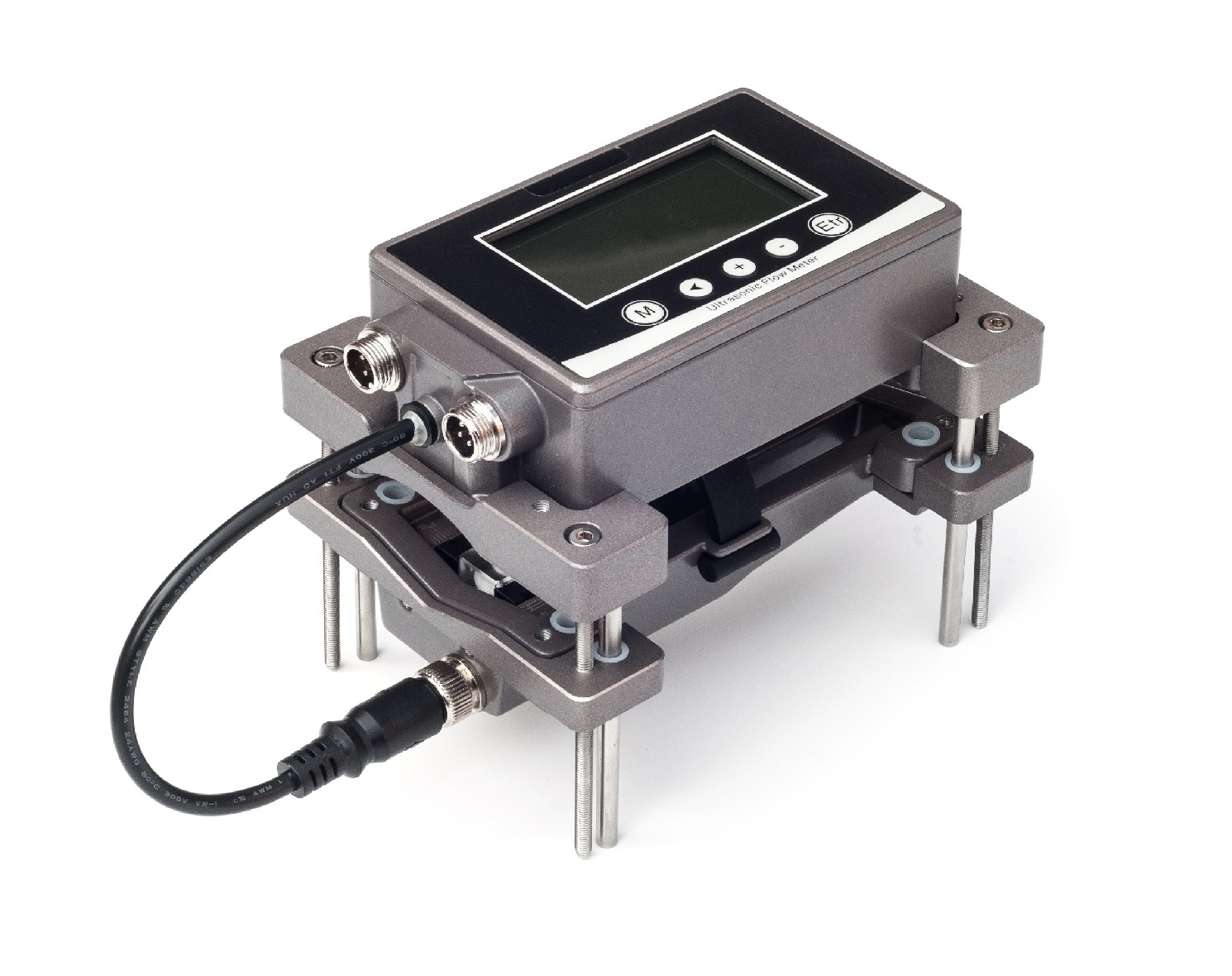

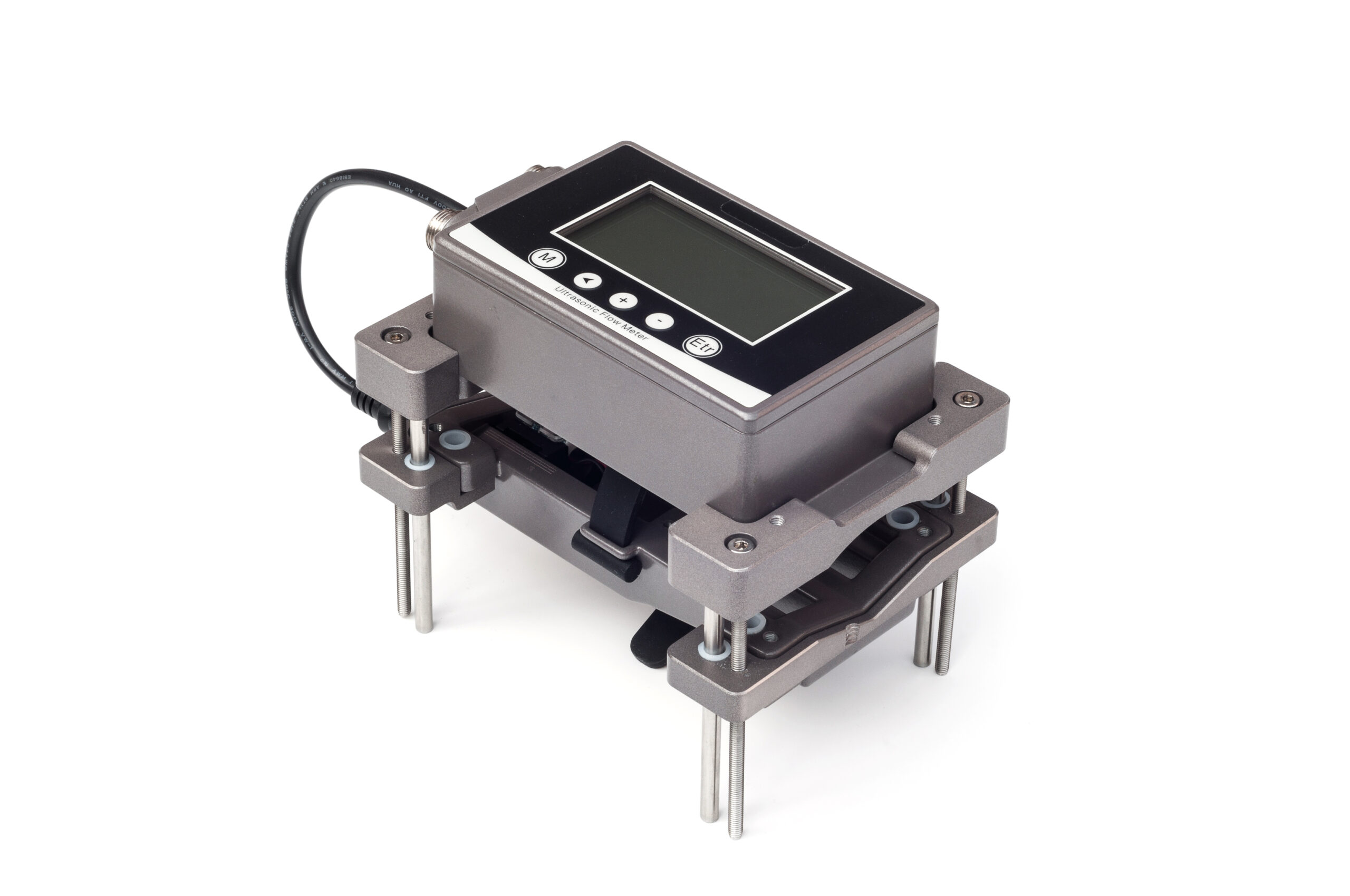

What is a Clamp-On Ultrasonic Flow Meter for Small Pipes?

Engineers need to understand the specific requirements for small pipe applications.

A clamp-on ultrasonic flow meter for small pipes is a specialized instrument with high-frequency transducers and optimized signal processing for accurate measurement in confined spaces.

Small Pipe Flow Meter Design

Based on my implementation experience:

Design Features

Key Components

Element Function Benefit Transducers Signal generation Enhanced penetration Electronics Signal processing Improved resolution Mounting system Secure attachment Stable readings Interface Data display Easy operation Technical Specifications

- Operating frequency

- Signal strength

- Mounting options

- Connection types

Application Areas

Common Uses

- HVAC systems

- Water distribution

- Chemical dosing

- Process control

Installation Requirements

- Space considerations

- Environmental factors

- Maintenance access

- Power supply needs

Conclusion

Clamp-on ultrasonic flow meters can effectively measure flow in small pipes when properly selected, installed, and maintained, though special attention to installation and operating conditions is crucial.