Many industries struggle with accurate liquid flow measurement, leading to process inefficiencies and quality control issues.

Ultrasonic flow meters measure liquid flow using sound waves, offering non-intrusive measurement with accuracy typically between ±0.5% to ±1.0% for clean liquids.

Ultrasonic Flow Meter Principles

Let me share my experience to help you understand if ultrasonic flow meters are right for your liquid applications.

What Are The Disadvantages of an Ultrasonic Flow Meter?

Understanding limitations helps prevent costly application mistakes.

Key disadvantages include sensitivity to fluid conditions, installation requirements, higher initial costs, and potential accuracy issues with dirty or aerated liquids.

Ultrasonic Flow Meter Limitations

From my field experience:

Major Limitations

-

Performance Factors

Limitation Impact Solution Air bubbles Signal disruption Proper installation Fluid particles Signal scatter Filter systems Installation Accuracy loss Correct placement Cost Budget constraints ROI analysis -

Application Challenges

- Signal path interference

- Temperature effects

- Maintenance requirements

- Calibration needs

Mitigation Strategies

-

Design Considerations

- Proper meter selection

- Installation planning

- Process optimization

- Maintenance scheduling

-

Operational Solutions

- Regular monitoring

- Preventive maintenance

- Staff training

- Performance validation

How Do You Measure The Flow of a Liquid?

Choosing the right measurement method is crucial for accuracy.

Ultrasonic flow meters use transit-time or Doppler techniques to measure liquid flow, with transit-time being more accurate for clean liquids.

Liquid Flow Measurement Methods

Based on my measurement expertise:

Measurement Techniques

-

Key Methods

Method Application Accuracy Transit-time Clean liquids ±0.5% Doppler Dirty liquids ±1-2% Cross-correlation Mixed flows ±2-3% Hybrid Various ±1% -

Selection Criteria

- Fluid properties

- Accuracy needs

- Installation conditions

- Budget constraints

Implementation Steps

-

System Design

- Flow analysis

- Meter selection

- Installation planning

- Validation methods

-

Operational Aspects

- Startup procedures

- Monitoring systems

- Maintenance plans

- Performance checks

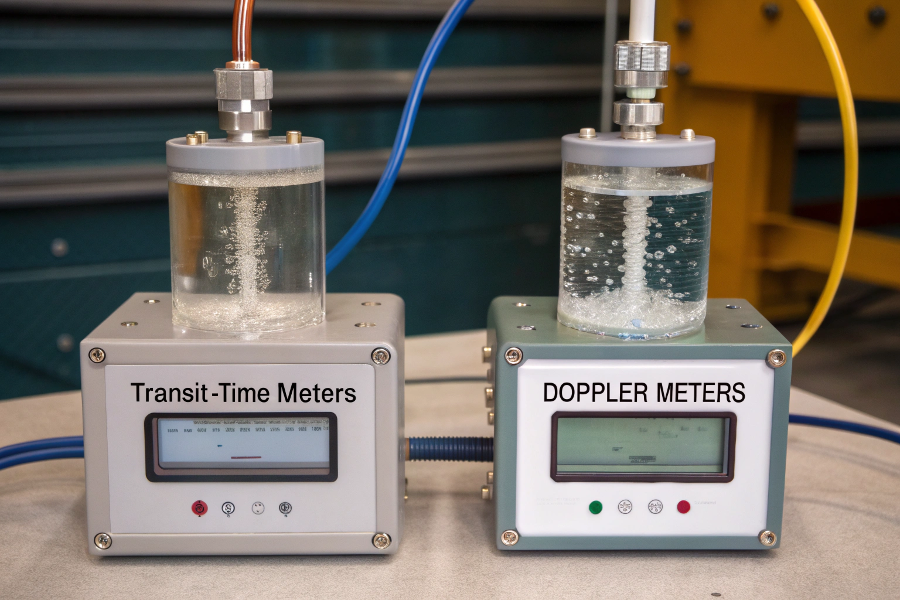

What Are The Two Types of Ultrasonic Flow Meters?

Understanding different types helps in selecting the right solution.

The two main types are transit-time meters for clean liquids and Doppler meters for liquids with suspended particles or bubbles.

Ultrasonic Flow Meter Types

Drawing from my technical knowledge:

Type Comparison

-

Characteristics

Feature Transit-time Doppler Accuracy Higher Lower Applications Clean fluids Dirty fluids Cost Higher Lower Maintenance Less More -

Operating Principles

- Signal processing

- Installation requirements

- Calibration methods

- Performance factors

Application Guidelines

-

Selection Criteria

- Fluid properties

- Accuracy needs

- Installation conditions

- Maintenance capabilities

-

Implementation Considerations

- Installation requirements

- Operational needs

- Maintenance plans

- Cost factors

What Ultrasonic Flow Meter is Best for Fluid with Slurries, Liquids with Bubbles, and Gases?

Choosing the wrong meter type can lead to measurement failures.

Doppler ultrasonic flow meters are best for slurries and liquids with bubbles, while specialized transit-time meters are needed for gases.

Flow Meter Application Guide

Based on my application experience:

Application-Specific Solutions

-

Media Compatibility

Media Type Best Meter Key Feature Slurries Doppler Particle reflection Aerated liquids Doppler Bubble detection Clean gases Special transit-time High sensitivity Mixed flows Hybrid systems Dual technology -

Performance Factors

- Signal strength

- Measurement stability

- Accuracy requirements

- Maintenance needs

Implementation Guidelines

-

System Design

- Process analysis

- Meter selection

- Installation planning

- Performance validation

-

Operational Aspects

- Startup procedures

- Monitoring systems

- Maintenance schedules

- Performance checks

Conclusion

Successful liquid flow measurement with ultrasonic meters requires understanding meter types, application limitations, and proper installation techniques for your specific needs.