Installing the wrong type of flow meter can damage your pipes and lead to costly production downtime.

A non-invasive flow meter, also known as a clamp-on meter, measures flow from outside the pipe without cutting or modifying the pipeline, making it ideal for existing installations.

Non-Invasive Flow Meter Installation

Let me share my experience to help you understand if this technology is right for your application.

What is a Non-Invasive Flow Meter?

Many plant managers worry about disrupting their processes to install new flow meters.

Non-invasive flow meters are external sensors that attach to the outside of pipes, measuring flow without contact with the process fluid, eliminating installation downtime and contamination risks.

Clamp-on Flow Meter Installation

From my field experience:

Key Benefits

-

Installation Advantages

Feature Benefit Impact External Mount No pipe cutting Zero downtime No fluid contact No contamination Process integrity Portable option Multiple uses Cost savings Quick install Easy maintenance Reduced labor -

Application Areas

- Retrofit projects

- Temporary measurement

- Clean utilities

- Hygienic processes

Technical Considerations

-

System Requirements

- Pipe material compatibility

- Surface condition

- Acoustic properties

- Installation access

-

Performance Factors

- Signal strength

- Flow profile

- Fluid properties

- Environmental conditions

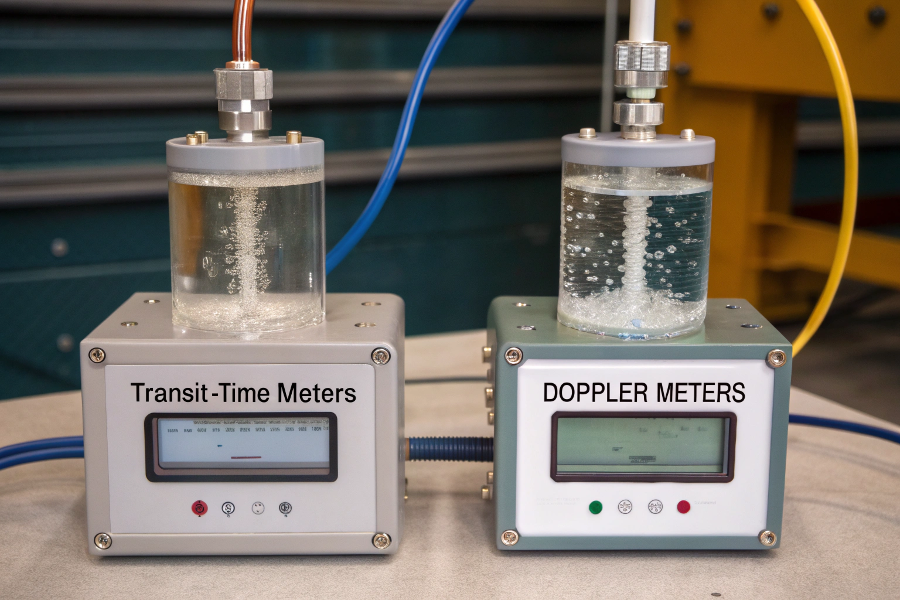

What Are the Two Types of Ultrasonic Flow Meters?

Choosing the wrong ultrasonic technology can result in unreliable measurements.

The two main types are transit-time meters for clean liquids and Doppler meters for liquids containing particles or bubbles.

Transit-Time vs Doppler Technology

Based on my implementation experience:

Transit-Time Technology

-

Operating Principles

Feature Description Application Method Time difference Clean liquids Accuracy Up to ±0.5% Precise control Installation Paired sensors Critical alignment Requirements Clean fluid Minimal bubbles -

Common Applications

- Water treatment

- Chemical processing

- HVAC systems

- Oil transfer

Doppler Technology

-

Performance Characteristics

Feature Description Application Method Frequency shift Dirty liquids Accuracy 1-2% typical Process monitoring Installation Single-sided Simple setup Requirements Particles/bubbles Good reflection -

Typical Uses

- Wastewater

- Slurries

- Mining

- Paper pulp

What is an Example of a Non-Invasive Flowmeter?

Finding practical examples helps understand real-world applications better.

Clamp-on ultrasonic flow meters are the most common non-invasive flowmeters, widely used in water distribution, HVAC systems, and industrial processes.

Non-Invasive Flow Meter Applications

Non-Invasive Flow Meter Applications

Drawing from my project experience:

Application Examples

-

Common Uses

Industry Application Benefits Water Distribution monitoring Easy installation HVAC Chilled water Energy efficiency Chemical Process control No contamination Power Cooling systems Reliability -

Success Factors

- Proper sizing

- Correct placement

- Regular maintenance

- Staff training

Implementation Guide

-

Installation Steps

- Site survey

- Pipe preparation

- Sensor mounting

- System validation

-

Best Practices

- Location selection

- Surface preparation

- Signal verification

- Documentation

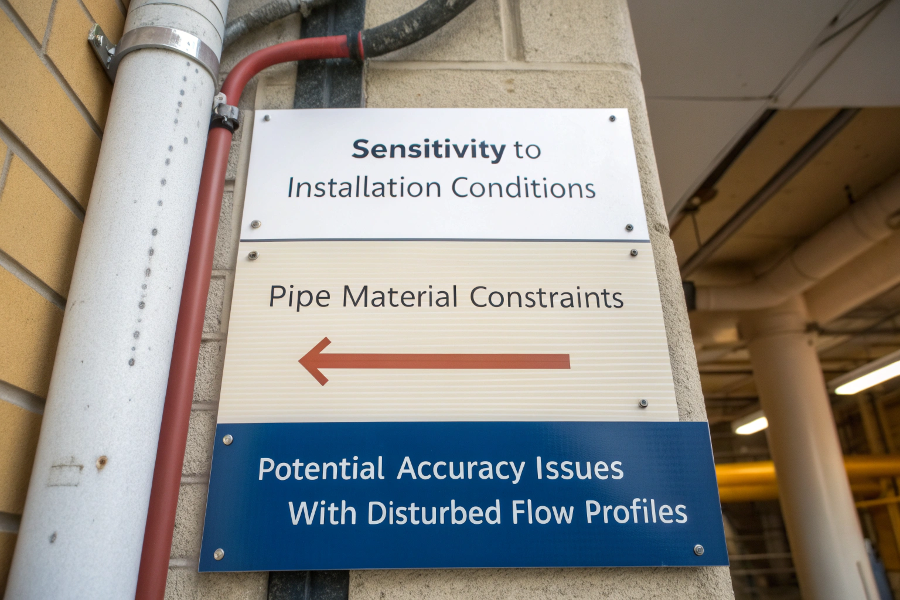

What Are the Disadvantages of an Ultrasonic Flow Meter?

Understanding limitations helps prevent application failures.

Main disadvantages include sensitivity to installation conditions, pipe material constraints, and potential accuracy issues with disturbed flow profiles.

Ultrasonic Flow Meter Limitations

From my troubleshooting experience:

Key Limitations

-

Technical Challenges

Challenge Impact Solution Installation Accuracy Proper setup Flow profile Measurement Straight run Signal quality Reliability Regular checks Temperature Performance Compensation -

Application Constraints

- Pipe condition

- Fluid properties

- Environmental factors

- Access requirements

Mitigation Strategies

-

Design Considerations

- Site selection

- Installation method

- Protection measures

- Maintenance access

-

Operational Solutions

- Regular calibration

- Staff training

- Preventive maintenance

- Performance monitoring

Conclusion

Non-invasive ultrasonic flow meters offer significant advantages for many applications, but success depends on proper technology selection, installation, and understanding of their limitations.