Measuring flow in large diameter pipes presents unique challenges that can lead to significant measurement errors and costly mistakes.

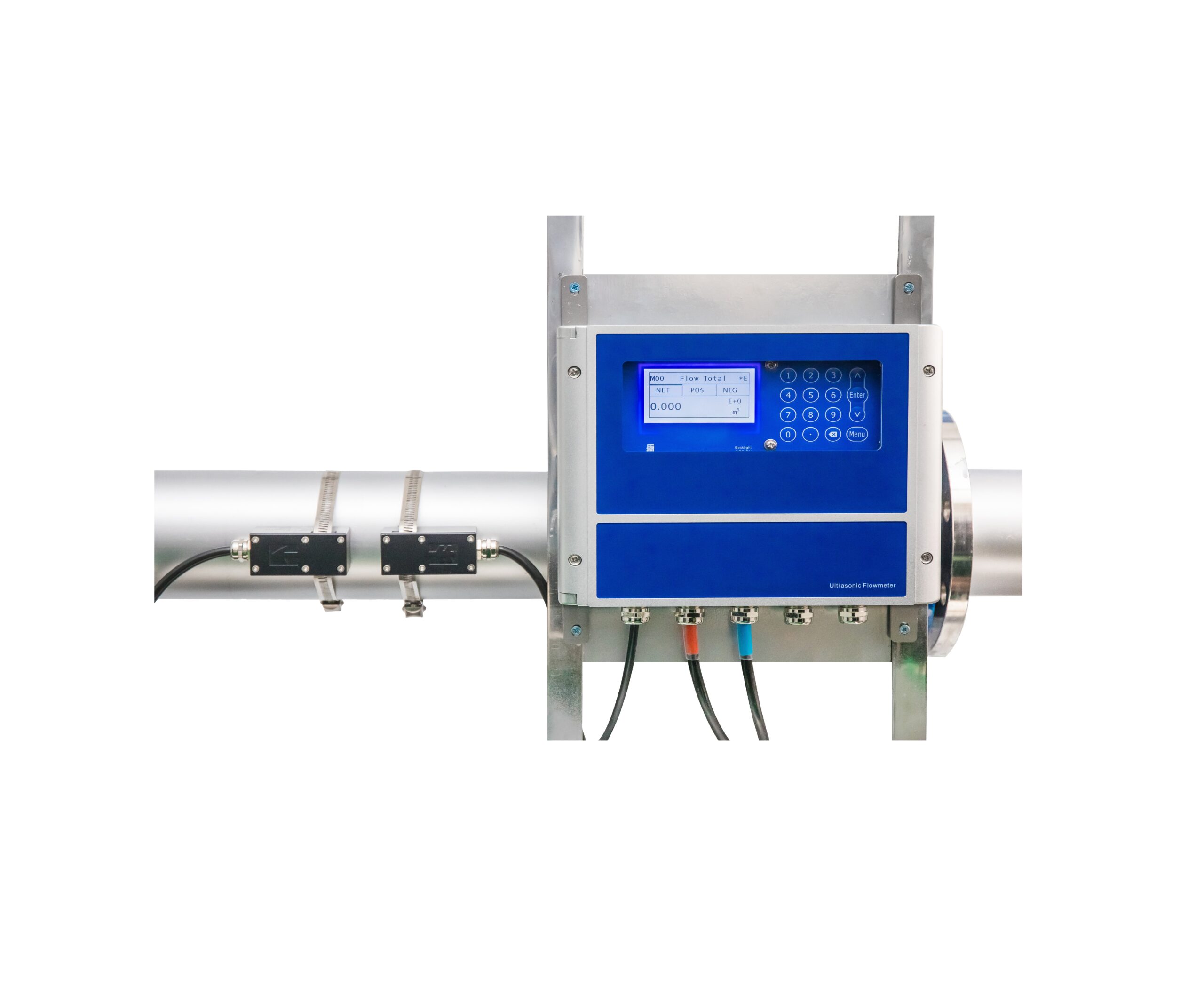

Ultrasonic flow meters are ideal for large diameter pipes (>12 inches) as they offer non-intrusive measurement, minimal pressure loss, and cost-effective installation compared to other technologies.

Ultrasonic Flow Meter on Large Diameter Pipe

Let me share my experience with large pipe applications to help you make informed decisions.

Which Flow Device is Suitable for Measuring Large Pipes?

Many engineers struggle to find cost-effective solutions for large pipe flow measurement.

For large pipes, clamp-on and insertion-type ultrasonic flow meters are most suitable due to their easy installation, maintenance accessibility, and lower overall cost.

Flow Measurement Devices for Large Pipes

Based on my field experience:

Technology Comparison

Flow Meter Options

Type Advantages Limitations Cost Factor Ultrasonic Non-intrusive, Easy install Profile sensitivity Medium Magnetic Accurate, No obstruction High cost, Installation Very High Differential Simple, Reliable Pressure loss Medium-High Vortex Robust, Low maintenance Size limitations High Installation Considerations

- Access requirements

- Maintenance needs

- Installation costs

- System downtime

Selection Criteria

Key Factors

- Pipe size range

- Flow conditions

- Budget constraints

- Accuracy needs

Practical Aspects

- Installation ease

- Maintenance access

- Calibration requirements

- Operating costs

What are the Limitations of Ultrasonic Flow Meter?

Understanding limitations helps prevent application failures and measurement errors.

Key limitations include flow profile sensitivity, straight run requirements, and the need for proper fluid conditions such as minimum turbidity and bubble content.

Ultrasonic Flow Meter Limitations

From my troubleshooting experience:

Technical Limitations

Performance Factors

Limitation Impact Solution Flow Profile Accuracy Proper installation Signal Strength Reliability Transducer selection Fluid Properties Measurement quality Application review Environmental Signal stability Protection measures Application Constraints

- Temperature effects

- Pressure limitations

- Fluid composition

- Installation space

Operational Challenges

Common Issues

- Signal interference

- Calibration drift

- Maintenance access

- Environmental effects

Mitigation Strategies

- Regular maintenance

- Staff training

- Signal monitoring

- Installation optimization

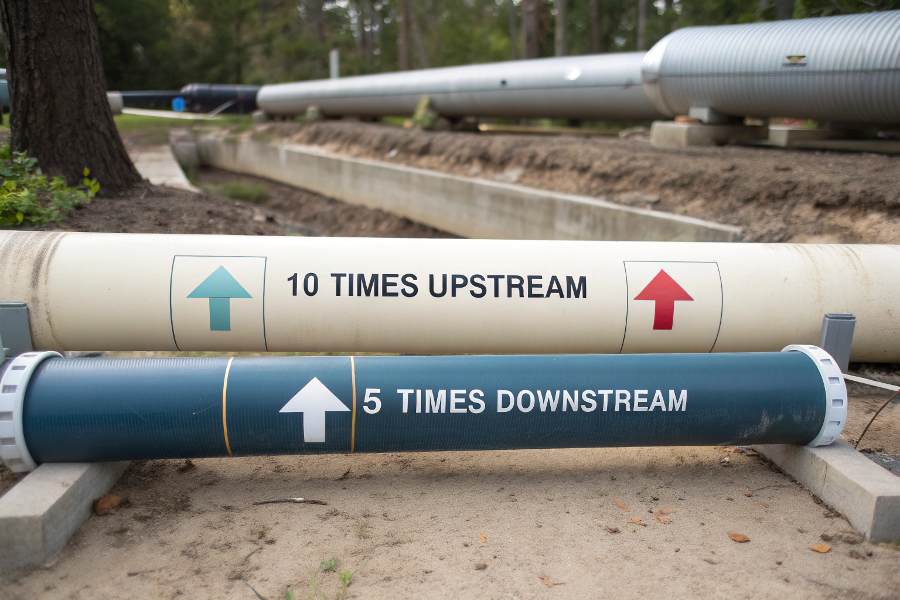

How Many Pipe Diameters for a Ultrasonic Flow Meter?

Incorrect straight run lengths are a common cause of measurement inaccuracy.

Most ultrasonic flow meters require 10 pipe diameters upstream and 5 pipe diameters downstream for accurate measurement, though this varies with pipe features.

Flow Meter Pipe Diameter Requirements

Drawing from my installation expertise:

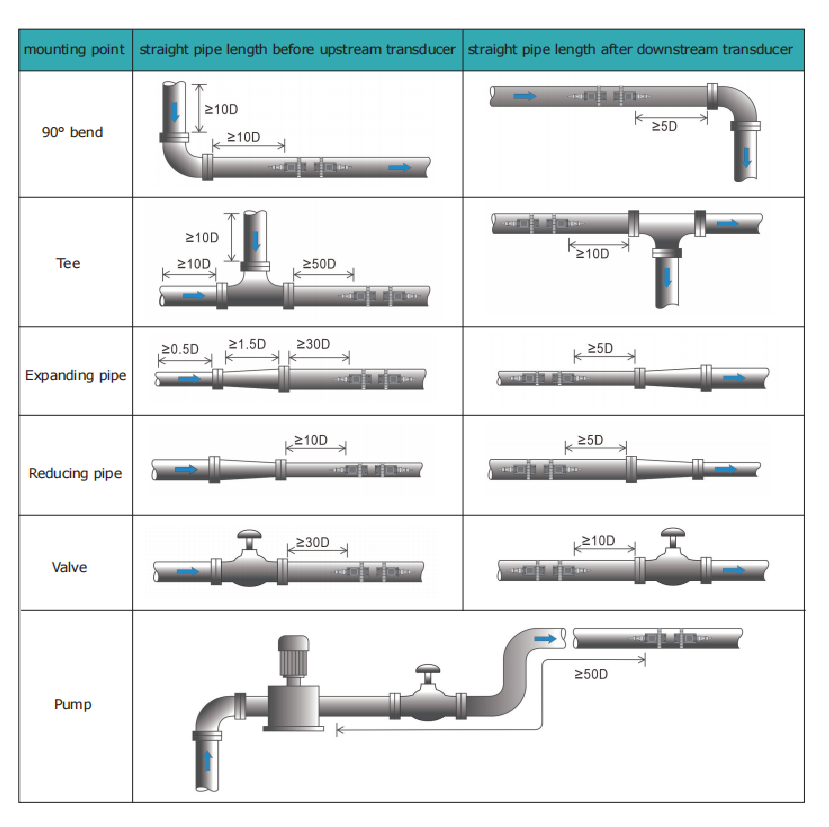

Straight Run Requirements

Disturbance Upstream Downstream Impact 90° Elbow 10D 5D Flow profile Double Bend 15D 5D Swirl effect Reducer 10D 5D Velocity change Valve 20D 5D Flow disturbance Critical Factors

- Flow profile

- Installation space

- Accuracy needs

- Pipe features

Optimization Strategies

Space Constraints

- Flow conditioners

- Multiple paths

- Location selection

- Installation type

Performance Enhancement

- Profile analysis

- Signal quality

- Calibration verification

- Regular monitoring

What is the Rule of Thumb for Flow Meter Pipe?

Poor pipe configuration choices often lead to measurement errors and system inefficiency.

The general rule is to maintain 10 pipe diameters of straight run upstream and 5 downstream, with the meter installed in a horizontal run whenever possible.

Flow Meter Pipe Configuration Rules

Based on my design experience:

Design Guidelines

Basic Rules

Aspect Requirement Purpose Orientation Horizontal Bubble prevention Fill Level Full pipe Accuracy Support Rigid mounting Stability Access Maintenance space Serviceability Installation Best Practices

- Pipe condition

- Mounting method

- Signal routing

- Environmental protection

Implementation Considerations

Practical Aspects

- Space availability

- Pipe modifications

- Installation costs

- Maintenance access

Quality Factors

- Material selection

- Surface preparation

- Support structure

- Protection measures

Conclusion

Successful implementation of ultrasonic flow meters in large pipes requires careful consideration of installation requirements, straight run specifications, and proper pipe configuration for optimal performance.