Choosing the wrong type of ultrasonic flow meter for clean fluids can lead to unnecessary costs and reduced accuracy.

For clean fluids without slurries or bubbles, transit-time ultrasonic flow meters are the best choice, offering accuracies up to ±0.5% and excellent repeatability.

Transit-Time Flow Measurement

Let me share my experience in helping customers select the right ultrasonic flow meters for clean fluid applications.

What Are the Different Types of Ultrasonic Flowmeters?

Making an uninformed choice between ultrasonic flow meter types can result in poor performance and wasted investment.

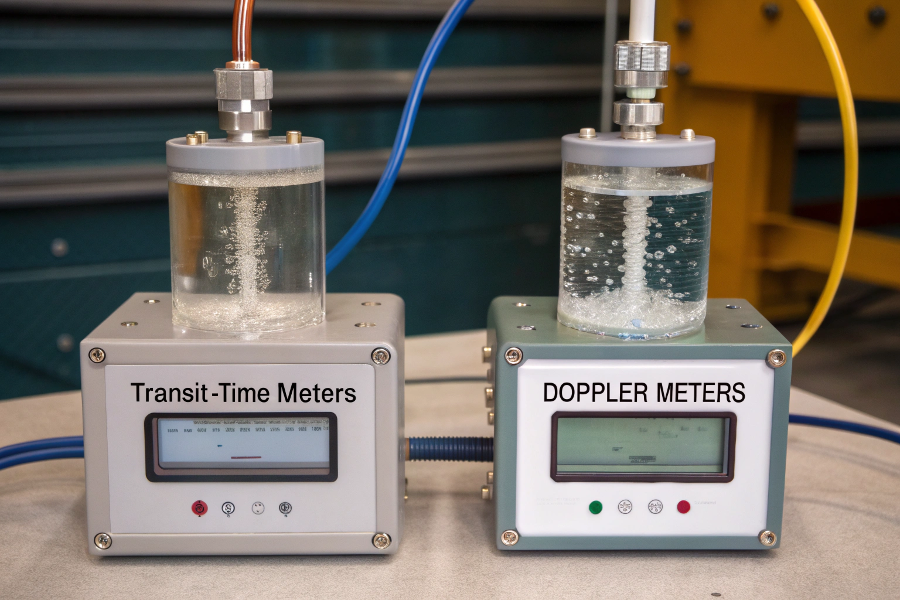

The main types are transit-time meters for clean fluids and Doppler meters for fluids with particles, with each type available in clamp-on and inline versions.

Ultrasonic Flow Meter Types

From my technical expertise:

Type Comparison

Main Categories

Type Best For Accuracy Installation Transit-Time Clean Fluids ±0.5% Clamp-on/Inline Doppler Dirty Fluids ±1-2% Clamp-on Hybrid Mixed Fluids ±1% Clamp-on/Inline Cross-Correlation Gas/Steam ±1-2% Inline Installation Methods

- Clamp-on benefits

- Inline advantages

- Sensor positioning

- Mounting requirements

Selection Criteria

Application Factors

- Fluid properties

- Flow conditions

- Accuracy needs

- Installation constraints

Performance Requirements

- Measurement range

- Response time

- Data output

- Communication needs

What Ultrasonic Flow Meter is Best for Fluid with Slurries, Liquids with Bubbles, and Gases?

Using transit-time meters for dirty fluids can lead to signal loss and measurement failures.

Doppler ultrasonic flow meters are optimal for fluids with particles and bubbles, while specialized ultrasonic meters are needed for gas measurement.

Doppler Flow Measurement

Based on my field experience:

Application Guidelines

Fluid Type Requirements

Media Meter Type Key Feature Slurries Doppler Particle Reflection Bubbly Liquids Doppler Bubble Detection Gases Specialized High Frequency Mixed Media Hybrid Dual Mode Performance Considerations

- Particle content

- Bubble size

- Flow velocity

- Signal strength

Installation Requirements

Mounting Considerations

- Pipe material

- Access points

- Straight run

- Signal path

Setup Parameters

- Sound velocity

- Fluid density

- Temperature range

- Flow profile

What Are the Two Types of Ultrasonic Devices?

Understanding the basic types helps in making informed decisions for your application.

The two fundamental types are transit-time devices for clean fluids and Doppler devices for fluids containing sound reflectors.

Ultrasonic Device Types

From my product knowledge:

Device Characteristics

Operating Principles

Feature Transit-Time Doppler Method Time Difference Frequency Shift Signal Path Direct Reflected Accuracy Higher Lower Applications Clean Fluids Dirty Fluids Technical Aspects

- Signal processing

- Sensor design

- Electronics

- Calibration methods

Application Specifics

Transit-Time Usage

- Water distribution

- Chemical processes

- Heat transfer

- Custody transfer

Doppler Applications

- Wastewater

- Mining slurries

- Paper pulp

- Food processing

What is the Most Accurate Type of Flow Meter?

Selecting a flow meter solely on accuracy claims can lead to disappointment if other factors aren’t considered.

Transit-time ultrasonic flow meters offer the highest accuracy among ultrasonic types, achieving up to ±0.5% in ideal conditions.

Flow Meter Accuracy Comparison

Drawing from my measurement expertise:

Accuracy Factors

Performance Comparison

Meter Type Best Accuracy Conditions Transit-Time ±0.5% Clean Fluid Coriolis ±0.1% Any Fluid Magnetic ±0.2% Conductive Vortex ±0.7% Clean Fluid Influencing Factors

- Installation quality

- Flow profile

- Fluid properties

- Environmental conditions

Optimization Tips

Accuracy Enhancement

- Proper installation

- Regular calibration

- Environmental protection

- Signal optimization

Maintenance Requirements

- Signal verification

- Zero checking

- Sensor cleaning

- Parameter updates

Conclusion

For clean fluids without particles or bubbles, transit-time ultrasonic flow meters provide the best combination of accuracy, reliability, and ease of use when properly installed and maintained.