Selecting the wrong flow measurement technology can lead to significant process inefficiencies, wasted resources, and inaccurate billing.

Ultrasonic flow meters measure fluid velocity by analyzing the time difference or frequency shift of ultrasonic signals traveling with and against the flow direction through a pipe.

Basic Ultrasonic Flow Meter Operation

Let me share my expertise in ultrasonic flow measurement technology, gained from years of designing and implementing flow solutions.

What is the Principle of Ultrasonic Flow Meter?

Understanding the working principle is crucial as incorrect implementation can result in measurement errors.

Ultrasonic flow meters operate on either transit-time or Doppler principles, using sound waves to measure flow velocity by detecting changes in signal transmission through the flowing medium.

%(percentage)ultrasonic-principle

Ultrasonic Flow Measurement Principle

From my experience designing flow measurement systems:

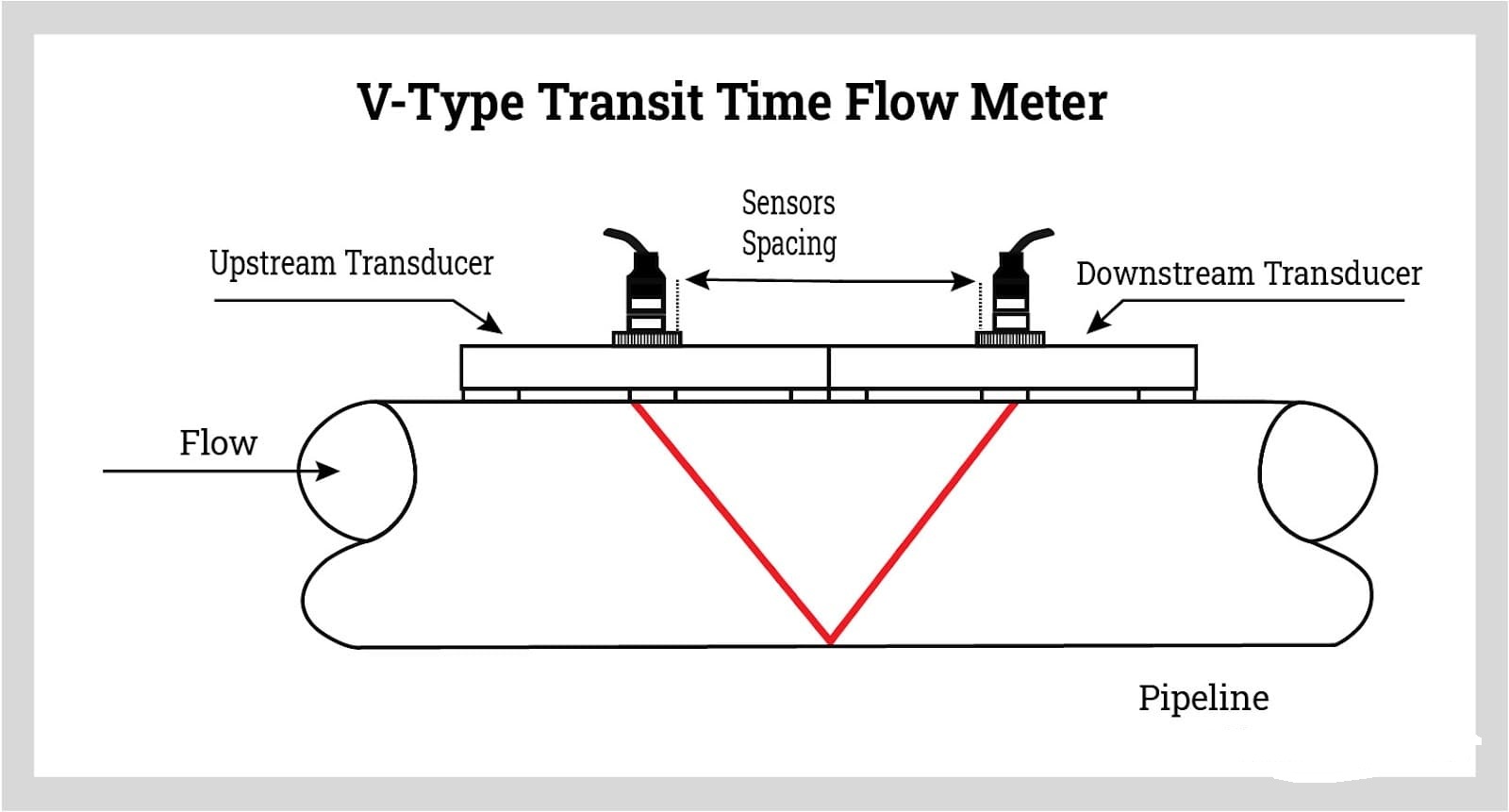

Transit-Time Operation

-

Basic Principles

Component Function Effect Transducers Signal Generation Sound Wave Creation Flow Path Signal Travel Time Measurement Electronics Processing Flow Calculation Display Output Reading Display -

Calculation Method

- Upstream time

- Downstream time

- Time difference

- Flow velocity

Doppler Operation

-

Key Elements

- Signal frequency

- Particle reflection

- Frequency shift

- Velocity correlation

-

Application Factors

- Particle content

- Flow profile

- Pipe conditions

- Installation requirements

These principles ensure accurate measurement.

What are the Disadvantages of an Ultrasonic Flow Meter?

Being unaware of ultrasonic flow meter limitations can lead to poor application choices and measurement failures.

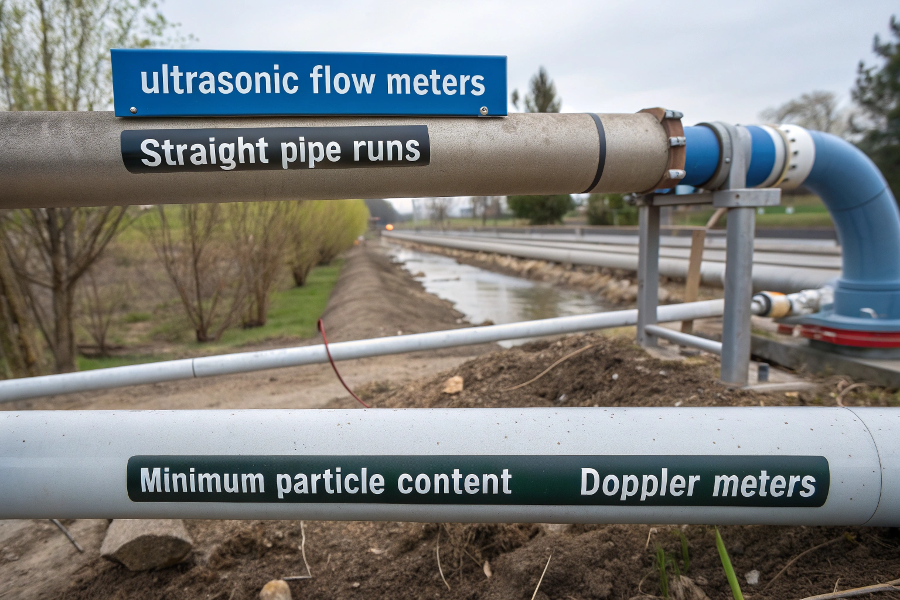

Main disadvantages include the need for sufficient straight pipe runs, sensitivity to flow profile disturbances, and requirements for minimum particle content in Doppler meters.

Ultrasonic Flow Meter Limitations

Drawing from my field experience:

Installation Challenges

-

Common Issues

Challenge Impact Solution Straight Run Flow Profile Extended Piping Signal Path Measurement Proper Mounting Fluid Content Signal Quality Application Check Environmental Performance Protection -

Operational Limits

- Flow range

- Temperature range

- Pressure limits

- Fluid properties

Maintenance Considerations

-

Regular Requirements

- Signal checking

- Calibration verification

- Transducer cleaning

- Electronics testing

-

Cost Factors

- Initial investment

- Installation expenses

- Maintenance needs

- Training requirements

These factors affect meter selection.

What are the Two Types of Ultrasonic Flow Meters?

Choosing the wrong type of ultrasonic flow meter for your application can result in measurement failures.

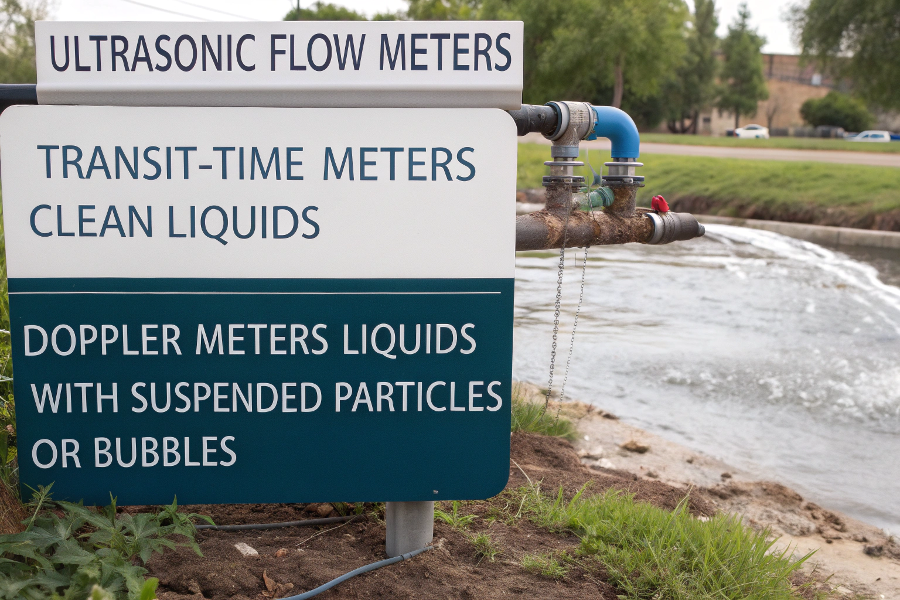

The two main types are transit-time meters for clean liquids and Doppler meters for liquids with suspended particles or bubbles.

Types of Ultrasonic Flow Meters

Types of Ultrasonic Flow Meters

Based on my product development experience:

Transit-Time Meters

-

Characteristics

Feature Benefit Application Clean Fluid High Accuracy Water Supply Bi-directional Flow Direction Custody Transfer No Obstruction Low Pressure Loss Large Pipes Wide Range Flexibility Various Fluids -

Installation Options

- Clamp-on

- Insertion

- Inline

- Multi-path

Doppler Meters

-

Key Features

- Particle measurement

- Single-sided mounting

- Maintenance-free

- Cost-effective

-

Application Areas

- Wastewater

- Slurries

- Chemical processing

- Mining operations

These options suit different needs.

How Accurate are Ultrasonic Flow Meters?

Misunderstanding accuracy specifications can lead to incorrect meter selection and measurement errors.

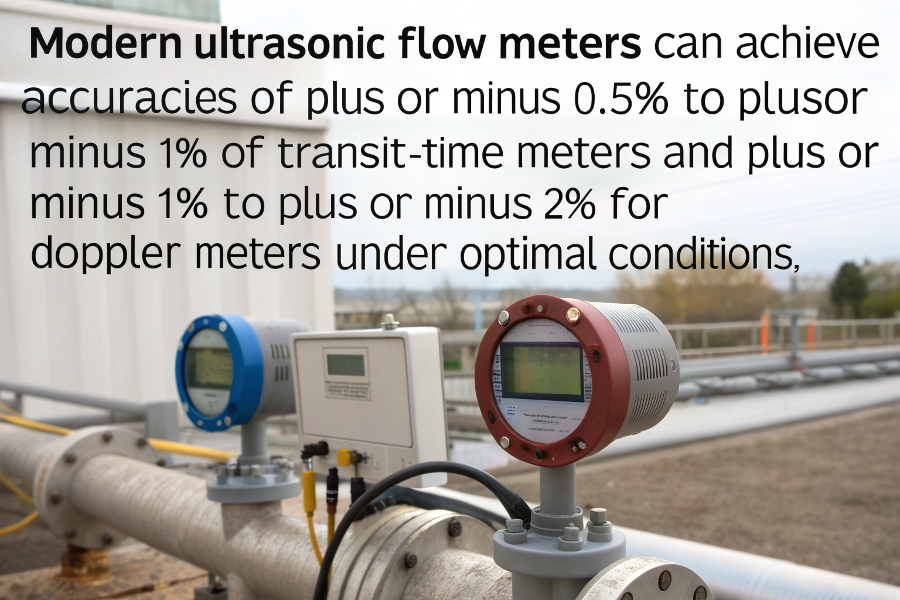

Modern ultrasonic flow meters can achieve accuracies of ±0.5% to ±1% of reading for transit-time meters and ±1% to ±2% for Doppler meters under optimal conditions.

Ultrasonic Flow Meter Accuracy Factors

From my testing experience:

Accuracy Factors

-

Key Parameters

Factor Impact Control Flow Profile Critical Installation Signal Quality Important Maintenance Calibration Essential Verification Electronics Significant Testing -

Environmental Effects

- Temperature changes

- Pressure variations

- Vibration

- Electrical noise

Performance Optimization

-

Installation Requirements

- Proper location

- Correct mounting

- Clean pipe surface

- Stable conditions

-

Maintenance Needs

- Regular checking

- Signal monitoring

- Zero verification

- Span testing

These practices ensure accuracy.

Conclusion

Ultrasonic flow meters offer versatile, accurate measurement solutions when properly selected, installed, and maintained, with specific types suited to different applications and operating conditions.