Many engineers and technicians struggle with choosing between pressure transmitters and transducers, often leading to costly mistakes and inefficient installations.

The main difference lies in their output signals: pressure transducers typically output millivolt signals, while pressure transmitters provide standardized 4-20mA or digital outputs.

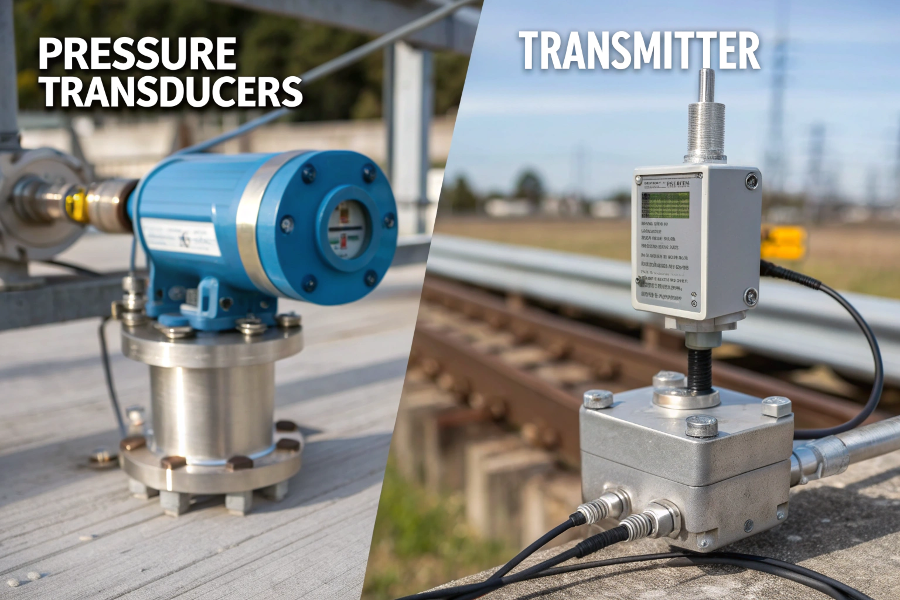

Pressure Transmitter vs Transducer Comparison

I’ve helped many clients make this choice, and I’ll explain the crucial differences that impact your application.

What is the Difference Between a Pressure Transducer and a Transmitter?

Choosing the wrong device can result in compatibility issues and poor system performance.

Pressure transducers convert pressure into electrical signals (typically mV), while transmitters include additional signal conditioning to provide standardized outputs suitable for long-distance transmission.

Signal Output Comparison

From my extensive experience:

Key Differences

Signal Characteristics

Feature Transducer Transmitter Output mV 4-20mA/Digital Range Limited Extended Power Low Higher Distance Short Long Application Considerations

- Installation requirements

- Signal processing needs

- Environmental factors

- System compatibility

Technical Aspects

Performance Features

- Accuracy levels

- Response times

- Temperature effects

- Stability ratings

Integration Requirements

- Power supply needs

- Wiring considerations

- Signal conditioning

- Communication protocols

These differences guide proper device selection.

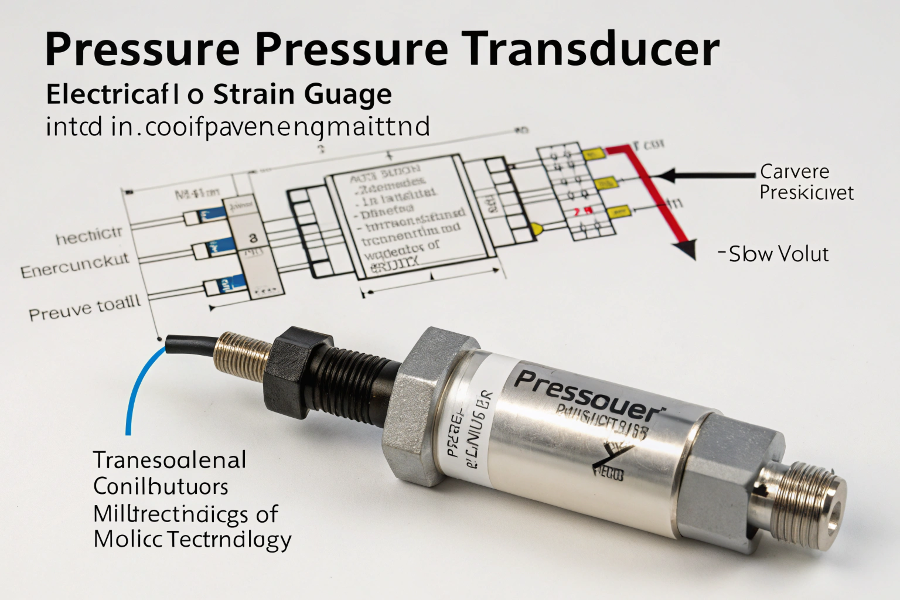

What is a Pressure Transducer?

Understanding pressure transducer basics helps prevent application mismatches.

A pressure transducer is a device that converts pressure into an electrical signal, typically using strain gauge or piezoelectric technology, producing a millivolt output.

Pressure Transducer Components

Based on my technical knowledge:

Operating Principles

Core Components

Component Function Purpose Sensing Element Pressure Detection Primary Strain Gauge Signal Generation Conversion Housing Protection Environmental Connection Process Interface Mounting Working Mechanism

- Pressure input

- Physical deformation

- Electrical generation

- Signal output

Application Considerations

Selection Criteria

- Pressure range

- Accuracy needs

- Environmental conditions

- Installation requirements

Common Applications

- Laboratory testing

- Research facilities

- Local monitoring

- OEM integration

These factors influence transducer effectiveness.

What is the Difference Between a Pressure Switch and a Pressure Transducer?

Confusion between switches and transducers can lead to inappropriate device selection.

Pressure switches provide binary (on/off) outputs at set pressure points, while transducers deliver continuous pressure measurement signals.

Switch vs Transducer Comparison

Drawing from my field experience:

Functional Differences

Operating Characteristics

Feature Switch Transducer Output Binary Continuous Function Control Measurement Adjustment Set Point Calibration Application Protection Monitoring Usage Scenarios

- Process control needs

- Safety requirements

- Monitoring demands

- System integration

Implementation Considerations

Selection Factors

- Application requirements

- System compatibility

- Environmental conditions

- Maintenance needs

Installation Aspects

- Mounting options

- Wiring requirements

- Adjustment access

- Maintenance space

These differences guide proper device selection.

What is a Pressure Transmitter Also Known As?

Understanding various terms helps avoid confusion when specifying equipment.

Pressure transmitters are also known as pressure sensors, pressure measurement transmitters, or pressure indicating transmitters, depending on their specific features and applications.

Pressure Transmitter Types

Based on my industry experience:

Common Terminology

Alternative Names

Term Context Usage Pressure Sensor General Measurement P/I Transmitter Industrial Control Pressure Monitor Process Indication Smart Transmitter Digital Communication Classification Basis

- Technology type

- Output signal

- Application area

- Communication protocol

Industry Applications

Usage Patterns

- Process industries

- Building automation

- Industrial control

- Research facilities

Selection Guidelines

- Industry standards

- System requirements

- Communication needs

- Performance specs

These terms reflect different application contexts.

Conclusion

Understanding the differences between pressure transmitters, transducers, and switches is crucial for selecting the right device for your application, ensuring optimal performance and system compatibility.