Improper installation of tuning fork level switches can lead to false readings, equipment damage, and costly process interruptions.

Install tuning fork level switches vertically in a location free from agitation, away from fill points, and with proper clearance from vessel walls. Ensure correct orientation and mounting angle.

Tuning Fork Level Switch Installation

Let me share my installation expertise gained from numerous industrial applications.

How Does a Tuning Fork Level Switch Work?

Understanding the working principle is crucial for proper installation and reliable operation.

The tuning fork vibrates at its natural frequency until contact with material dampens the vibration, triggering a switch output. This simple principle makes it highly reliable.

Tuning Fork Operating Principle

From my installation experience:

Core Components

System Elements

Component Function Installation Consideration Fork Tines Sensing element Orientation critical Housing Protection Seal integrity Electronics Signal processing Access for wiring Process Connection Mounting Proper threading Installation Requirements

- Clearance needs

- Orientation marking

- Wiring access

- Sealing requirements

Operation Factors

Process Conditions

- Material properties

- Flow patterns

- Temperature effects

- Pressure limits

Environmental Considerations

- Ambient conditions

- Vibration sources

- Cleaning access

- Maintenance space

These factors ensure optimal performance.

How to Test a Level Switch?

Regular testing ensures reliable operation and prevents unexpected failures.

Test level switches by verifying electrical connections, simulating material contact, and checking switch response. Document results for maintenance records.

Level Switch Testing Procedure

Based on my maintenance experience:

Testing Procedure

Electrical Tests

Step Action Expected Result Power Check Verify supply Correct voltage Output Test Simulate activation Proper switching Continuity Check wiring Good connections Ground Verify grounding Proper connection Mechanical Checks

- Fork cleanliness

- Mount security

- Seal condition

- Housing integrity

Verification Methods

Functional Testing

- Manual activation

- Response time

- Output verification

- Alarm function

Documentation

- Test results

- Maintenance records

- Calibration data

- Issue tracking

These tests ensure reliable operation.

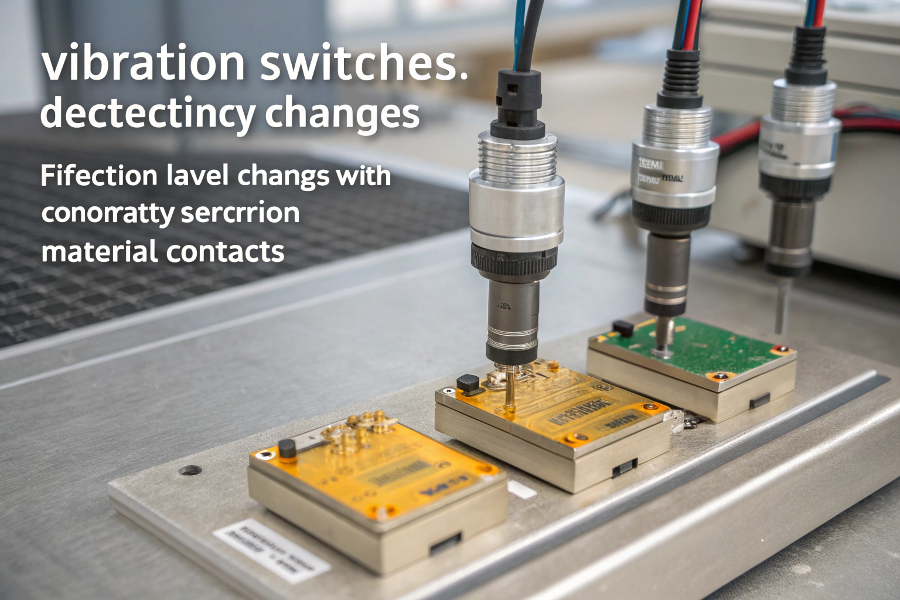

How Does a Vibration Switch Work in Level Measurement?

Understanding vibration-based measurement helps optimize installation for best performance.

Vibration switches detect level changes through frequency shifts when material contacts the sensor, requiring proper positioning for accurate detection.

Vibration Switch Operation

Drawing from my field experience:

Operating Principles

Detection Method

Phase Action Installation Impact Vibration Continuous operation Stable mounting Contact Material presence Clear access Processing Signal analysis Electronics protection Output Status change Proper wiring Installation Considerations

- Mounting stability

- Process isolation

- Signal routing

- Environmental protection

Performance Factors

Application Requirements

- Material properties

- Process conditions

- Response needs

- Reliability demands

Installation Optimization

- Position selection

- Mounting method

- Wiring approach

- Protection needs

These factors guide proper installation.

Where Should the Tuning Fork Be Placed?

Proper placement is crucial for accurate level detection and long-term reliability.

Place tuning forks away from fill streams, agitators, and vessel walls. Install vertically for liquids and angled for solids, ensuring proper clearance.

Tuning Fork Placement Guidelines

Based on my installation expertise:

Placement Guidelines

Location Selection

Factor Requirement Reason Fill Point Away from stream Prevent false triggers Wall Distance Minimum clearance Avoid interference Agitation Protected location Ensure stability Access Maintenance reach Enable service Mounting Considerations

- Orientation angle

- Process connection

- Support needs

- Safety access

Installation Best Practices

Physical Requirements

- Mounting strength

- Vibration isolation

- Temperature limits

- Pressure rating

Operational Needs

- Cleaning access

- Signal routing

- Protection method

- Testing ability

These guidelines ensure optimal performance.

Conclusion

Successful tuning fork level switch installation requires proper positioning, careful attention to mounting details, and consideration of process conditions to ensure reliable long-term operation.