Selecting the wrong flow meter in oil and gas applications can result in millions in revenue loss and compliance issues.

In the oil and gas industry, common flow meters include differential pressure devices, Coriolis meters, ultrasonic meters, and turbine meters, each serving specific measurement needs.

Oil and Gas Flow Meter Applications

Let me share insights from my experience in oil and gas flow measurement solutions.

What are the Different Types of Flow Meters?

Improper flow meter selection can lead to significant measurement errors and operational inefficiencies.

Flow meters in oil and gas applications include differential pressure, Coriolis, ultrasonic, turbine, positive displacement, and vortex meters, each designed for specific fluid conditions.

Types of Flow Meters in Oil and Gas

From my field experience:

Technology Overview

Primary Technologies

Type Best Application Typical Accuracy Coriolis Custody Transfer ±0.1% Ultrasonic Pipeline Monitoring ±0.5% DP Meters Well Testing ±1.0% Turbine High Flow Rates ±0.5% Selection Factors

- Process conditions

- Fluid properties

- Measurement requirements

- Environmental conditions

Application Considerations

Installation Requirements

- Space constraints

- Straight run needs

- Maintenance access

- Power availability

Operational Factors

- Pressure loss

- Turndown ratio

- Maintenance needs

- Calibration requirements

I’ve found these considerations crucial for successful implementations.

What are the Different Types of Gas Flow Meters?

Gas flow measurement errors can significantly impact custody transfer and process control accuracy.

Gas flow meters commonly used include ultrasonic, turbine, thermal mass, and differential pressure devices, with selection based on pressure, temperature, and flow conditions.

Gas Flow Meter Technologies

Based on my gas measurement experience:

Gas Measurement Technologies

Common Applications

Meter Type Primary Use Key Advantage Ultrasonic Pipeline Non-intrusive Turbine High Flow High accuracy Thermal Low Flow Direct mass flow DP Well Testing Cost-effective Operating Parameters

- Flow range

- Pressure ratings

- Temperature limits

- Gas composition

Performance Considerations

Critical Factors

- Pressure loss

- Rangeability

- Installation effects

- Maintenance needs

Installation Requirements

- Straight runs

- Orientation

- Protection needs

- Signal processing

These insights come from numerous gas measurement projects.

What is the Most Commonly Used Flow Meter?

Making uninformed decisions about flow meter selection can result in unnecessary costs and performance issues.

Differential pressure flow meters remain the most widely used in oil and gas, offering reliability, familiarity, and cost-effectiveness for many applications.

Common Flow Meter Applications

From my industry observations:

Popular Technologies

Usage Statistics

Meter Type Market Share Main Application DP Devices 40% Process Control Coriolis 20% Custody Transfer Ultrasonic 15% Pipeline Others 25% Various Selection Drivers

- Installation cost

- Maintenance needs

- Familiarity

- Regulatory requirements

Application Analysis

Industry Preferences

- Upstream operations

- Midstream transport

- Downstream processing

- Custody transfer

Technology Trends

- Smart diagnostics

- Wireless connectivity

- Remote monitoring

- Digital integration

Understanding these trends helps in making informed decisions.

What are the 4 Devices That Measure Flow?

Overlooking key flow measurement technologies can limit your ability to optimize process performance.

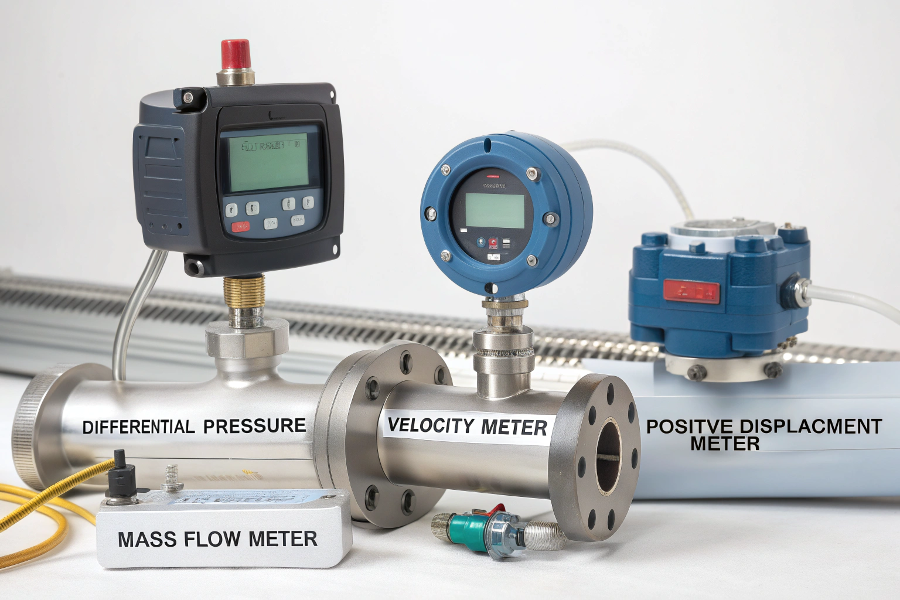

The four fundamental flow measurement devices are differential pressure devices, velocity meters, positive displacement meters, and mass flow meters.

Flow Measurement Device Categories

Based on my implementation experience:

Fundamental Categories

Device Comparison

Category Examples Best For DP Devices Orifice, Venturi Simple, reliable Velocity Turbine, Vortex High flow rates PD Meters Rotary, Piston High accuracy Mass Flow Coriolis, Thermal Direct mass measurement Operating Principles

- Pressure differential

- Flow velocity

- Volume displacement

- Mass measurement

Selection Guidelines

Application Factors

- Flow conditions

- Accuracy needs

- Maintenance capability

- Budget constraints

Installation Requirements

- Space limitations

- Straight runs

- Power needs

- Communication requirements

These categories cover most measurement needs.

Conclusion

Understanding flow meter types, their applications, and limitations is crucial for selecting the right technology for oil and gas industry measurement requirements.