Excessive pressure drop in flow meters can lead to energy waste, pump strain, and reduced system efficiency.

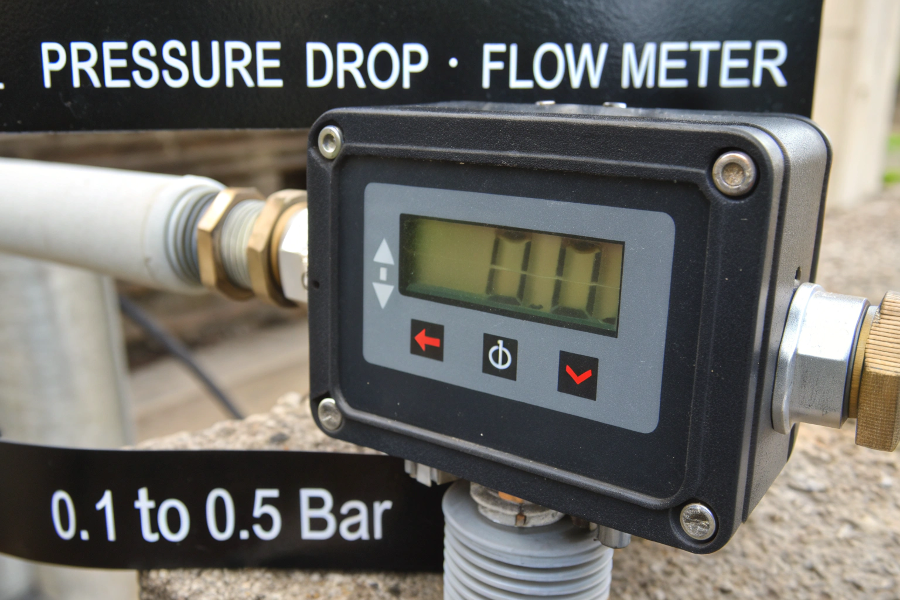

Flow meter pressure drop is the loss in pressure as fluid moves through the meter, typically ranging from 0.1 to 0.5 bar, depending on the meter type and flow conditions.

Flow Meter Pressure Drop Illustration

I’ve dealt with numerous pressure drop challenges in my flow measurement projects, and here’s what I’ve learned.

What is the Pressure Drop in a Flow Meter?

Unknown pressure drop can cause system design failures and operational inefficiencies.

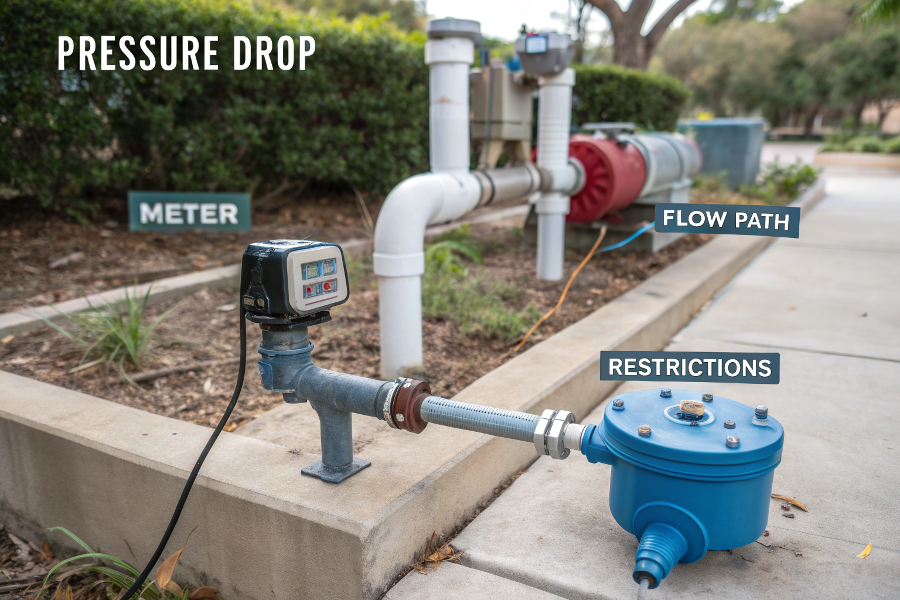

Pressure drop occurs when fluid energy is lost due to friction and flow path restrictions within the meter, varying by meter type, size, and flow rate.

Pressure Drop Mechanism

From my field experience:

Pressure Drop Characteristics

Meter Type Comparison

Meter Type Typical Drop Flow Range Magnetic Very Low Wide Ultrasonic Negligible Wide Vortex Medium Limited Orifice High Limited Impact Factors

- Flow velocity

- Fluid viscosity

- Meter geometry

- Installation effects

Design Considerations

System Requirements

- Available pressure

- Energy costs

- Pump capacity

- Process limits

Selection Criteria

- Operating range

- Accuracy needs

- Maintenance access

- Cost considerations

Understanding pressure drop is crucial for system design.

How to Calculate Pressure Drop from Flow Rate?

Incorrect pressure drop calculations can lead to undersized systems and operational problems.

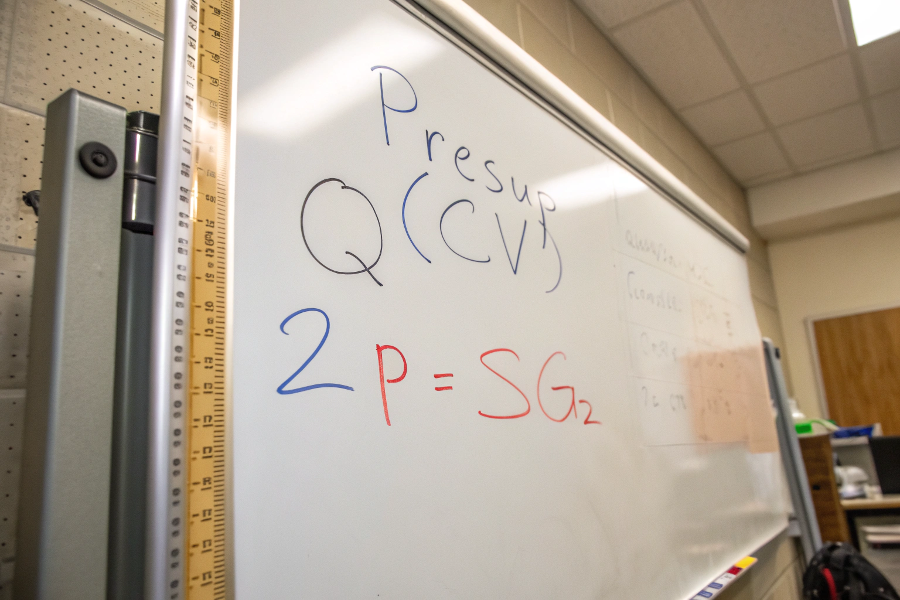

Pressure drop calculation uses the flow coefficient (Cv), flow rate, and fluid specific gravity in the formula: ΔP = (Q/Cv)² × SG, where ΔP is pressure drop.

Pressure Drop Calculation Method

Based on my calculation experience:

Calculation Methods

Basic Parameters

Parameter Symbol Units Flow Rate Q GPM Flow Coefficient Cv – Specific Gravity SG – Pressure Drop ΔP PSI Correction Factors

- Temperature effects

- Viscosity impacts

- Pipe size

- Installation factors

Application Steps

Data Collection

- Flow conditions

- Fluid properties

- System parameters

- Environmental factors

Calculation Process

- Basic equation

- Corrections

- Verification

- Documentation

Accurate calculations ensure proper sizing.

How Do You Measure Pressure Drop?

Inaccurate pressure drop measurement can result in poor system optimization and energy waste.

Pressure drop is measured using differential pressure gauges or transmitters installed at specific points before and after the flow meter, following proper installation guidelines.

Pressure Drop Measurement Setup

From my measurement experience:

Measurement Methods

Equipment Options

Method Accuracy Application DP Transmitter High Continuous Gauges Medium Spot Check Manometer Basic Simple Test Data Logger Advanced Analysis Installation Requirements

- Tap locations

- Connection size

- Isolation valves

- Calibration needs

Measurement Process

Setup Steps

- Equipment selection

- Installation

- Zero verification

- Range setting

Data Collection

- Reading frequency

- Documentation

- Analysis

- Reporting

Proper measurement ensures accurate results.

What is the Typical Pressure Drop on a Coriolis Flow Meter?

Unexpected Coriolis meter pressure drop can compromise system performance and measurement accuracy.

Coriolis flow meters typically have pressure drops ranging from 0.5 to 1.5 bar, varying with flow rate, tube design, and fluid properties.

Coriolis Pressure Characteristics

Design Factors

Feature Impact Consideration Tube Size High Flow capacity Tube Shape Medium Installation Flow Rate High Operation Fluid Type Medium Application Operating Conditions

- Flow range

- Fluid density

- Temperature

- Pressure limits

Application Guidelines

Selection Criteria

- Process requirements

- Pressure availability

- Accuracy needs

- Cost factors

Installation Considerations

- Mounting position

- Support needs

- Maintenance access

- Environmental factors

Understanding Coriolis characteristics ensures proper application.

Conclusion

Understanding and properly managing flow meter pressure drop is crucial for system efficiency, accurate measurement, and optimal operation of flow measurement systems.