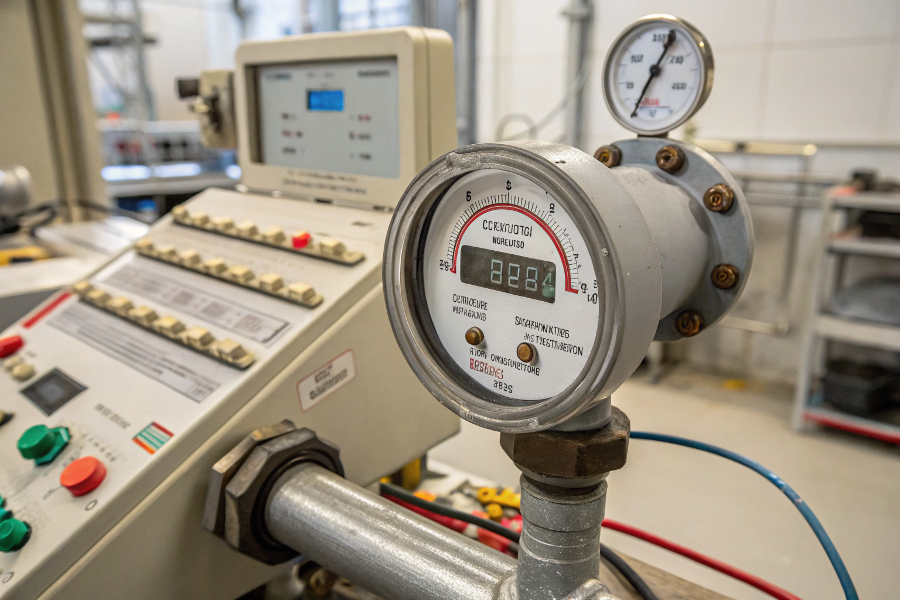

Flow meter issues can cause significant production losses and measurement inaccuracies if not properly addressed.

Common flow meter concerns include accuracy validation, installation requirements, measurement units, and troubleshooting procedures that affect reliable flow measurement.

Flow Meter Operation Overview

Let me share insights from my years of experience solving flow measurement challenges.

How to Tell if a Flow Meter is Bad?

Failing to identify flow meter problems early can result in costly measurement errors and process inefficiencies.

A bad flow meter typically shows symptoms like erratic readings, zero output, unusual noise, visible damage, or consistent deviation from expected values.

Flow Meter Diagnostic Indicators

From my troubleshooting experience:

Common Warning Signs

Performance Indicators

Symptom Possible Cause Action Required Zero Reading Power/Signal Issue Check connections Erratic Output Process/Noise Verify installation Drift Calibration Recalibrate No Response Sensor Failure Replace/Repair Physical Indicators

- Visible damage

- Unusual sounds

- Leakage

- Corrosion signs

Verification Methods

Testing Procedures

- Signal verification

- Zero check

- Span validation

- Comparison testing

Documentation Review

- Historical data

- Maintenance records

- Calibration certificates

- Process conditions

Regular monitoring prevents failures.

How Much Pipe Before and After a Flow Meter?

Incorrect pipe lengths can severely impact measurement accuracy and meter performance.

Most flow meters require 10 diameters of straight pipe upstream and 5 diameters downstream for accurate measurement, though requirements vary by meter type.

Flow Meter Piping Requirements

Based on my installation experience:

Installation Requirements

Meter Type Upstream Downstream Magnetic 5D 3D Ultrasonic 10D 5D Vortex 15D 5D Turbine 20D 10D Influencing Factors

- Flow profile

- Pipe fittings

- Valve locations

- Process conditions

Installation Guidelines

Best Practices

- Proper orientation

- Support requirements

- Grounding needs

- Access considerations

Common Challenges

- Space constraints

- Flow conditioning

- Vibration control

- Maintenance access

Proper installation ensures accuracy.

What Are The 5 Different Units Used to Measure Flow Rate?

Using incorrect flow units can lead to calculation errors and process control problems.

The five main flow rate units are volumetric (m³/h, GPM), mass (kg/h, lb/min), velocity (m/s, ft/s), standardized volume (SCFM), and percentages of range.

Flow Measurement Units

From my measurement experience:

Flow Unit Categories

Common Units

Type Units Applications Volumetric m³/h, GPM Liquids Mass kg/h, lb/min Gas/Steam Velocity m/s, ft/s Air/Gas Standard SCFM, Nm³/h Gas Percentage % of range Control Conversion Factors

- Temperature effects

- Pressure impacts

- Density considerations

- Standard conditions

Application Guidelines

Selection Criteria

- Industry standards

- Process requirements

- Control systems

- Documentation needs

Implementation

- Unit configuration

- Display settings

- Data logging

- Reporting formats

Proper units ensure clarity.

How to Troubleshoot a Flow Meter?

Poor troubleshooting approaches can waste time and fail to resolve underlying meter issues.

Flow meter troubleshooting involves systematic checking of power, signal, sensor, and process conditions, following manufacturer guidelines and documented procedures.

Flow Meter Troubleshooting Process

Based on my maintenance experience:

Troubleshooting Process

Systematic Approach

Step Action Purpose Visual Inspect meter Find damage Electrical Check power/signal Verify connectivity Process Review conditions Validate operation Testing Perform diagnostics Identify issues Common Problems

- Zero drift

- Noise interference

- Calibration errors

- Installation issues

Resolution Steps

Documentation

- Problem description

- Actions taken

- Results observed

- Follow-up needed

Verification

- Performance check

- Signal validation

- Process review

- Documentation

Systematic troubleshooting ensures success.

Conclusion

Understanding flow meter diagnostics, installation requirements, measurement units, and troubleshooting procedures is essential for maintaining accurate and reliable flow measurement systems.