Recently, a petrochemical plant lost $50,000 due to inaccurate measurements caused by improper flow meter installation. Their experience shows why proper installation is crucial.

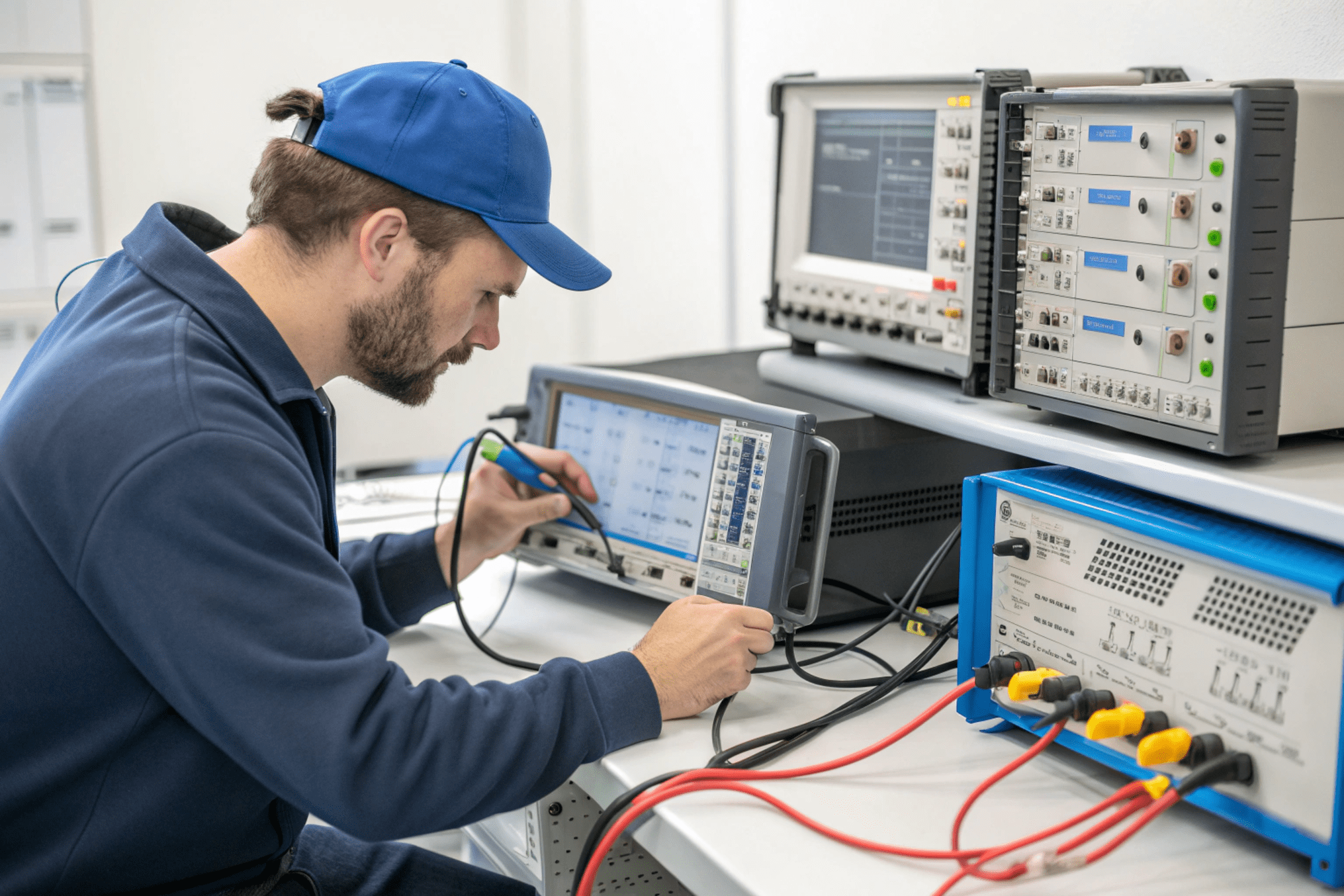

Flow meter installation requires proper straight pipe lengths, correct orientation, appropriate mounting location, and consideration of fluid conditions. These factors ensure measurement accuracy and long-term reliability.

Let me share insights from my 15 years of experience helping customers achieve optimal flow meter performance through proper installation.

What Are the Basic Flow Meter Installation Requirements?

Last month, I helped a water treatment facility improve their measurement accuracy by 15% just by correcting their installation setup.

Essential requirements include sufficient straight pipe runs, proper orientation, secure mounting, appropriate process connections, and protection from environmental factors.

Critical Installation Factors

Straight Run Requirements

Meter Type Upstream Downstream Reason Electromagnetic 10D 5D Flow profile Ultrasonic 10D 5D Signal quality Vortex 15D 5D Stability Coriolis 0D 0D Mass measurement Key Considerations

- Flow direction

- Pipe support

- Grounding requirements

- Accessibility for maintenance

- Protection from vibration

How Do You Select the Optimal Installation Location?

A food processing plant saved $20,000 in maintenance costs by relocating their flow meters to more suitable locations based on my recommendations.

The ideal location should have stable flow conditions, be easily accessible for maintenance, protect from environmental factors, and meet straight run requirements.

Location Selection Criteria

Environmental Factors

Factor Impact Solution Consideration Temperature Accuracy Insulation Operating range Vibration Stability Dampening Mounting EMI Signal Shielding Cable routing Weather Protection Enclosure IP rating Accessibility Requirements

- Maintenance access

- Reading display

- Cable connections

- Calibration points

- Safety considerations

What Safety Measures Are Essential During Installation?

I’ve overseen hundreds of installations where proper safety protocols prevented potential accidents and equipment damage.

Safety requirements include proper lockout/tagout procedures, pressure testing, electrical safety measures, and compliance with local regulations and standards.

Safety Protocol Implementation

Safety Checklist

Step Action Verification Documentation Isolation LOTO Double check Permit Pressure test Leak check Pressure test Report Electrical Grounding Continuity test Certificate PPE Equipment Inspection Checklist

How Should You Handle Technical Configuration?

Through careful configuration, I helped a chemical plant achieve 3% better accuracy and reduce maintenance frequency by 50%.

Technical configuration involves calibration, zero point setting, parameter adjustment, and communication setup. These steps ensure optimal performance.

Technical Configuration Steps

Configuration Process

Setup Parameters

Parameter Purpose Setting Method Verification Zero point Baseline Auto/Manual Zero flow Span Range Calculation Known flow Units Display Programming Check Outputs Signals Configuration Loop test Calibration Steps

- Zero point verification

- Span adjustment

- Linear check

- Output verification

- Documentation

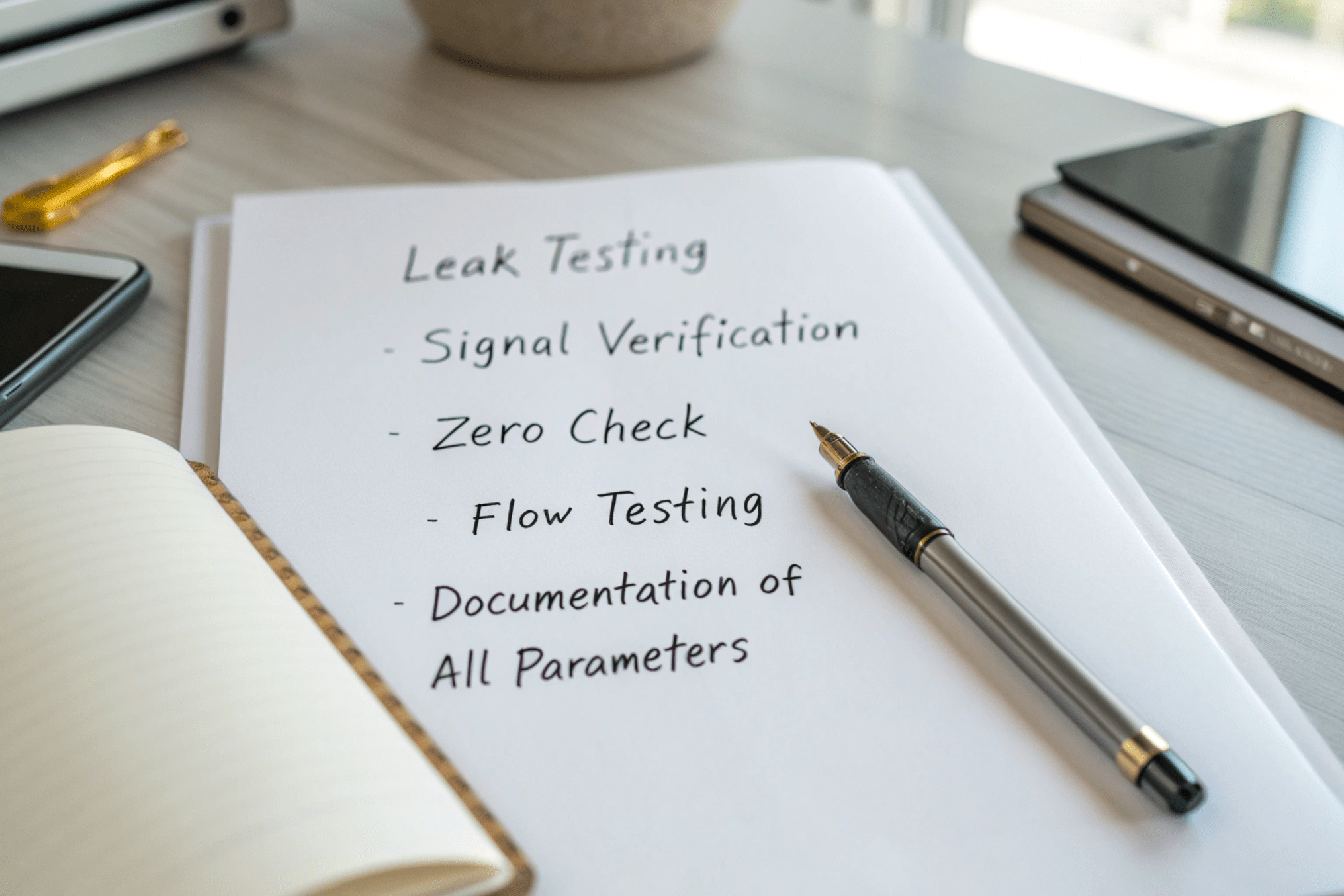

What Post-Installation Checks Are Necessary?

Recent experience with a mining operation showed how thorough post-installation checks prevented 90% of early-life failures.

Post-installation verification includes leak testing, signal verification, zero check, flow testing, and documentation of all parameters.

Post-Installation Verification

Verification Process

Testing Requirements

Test Type Method Acceptance Documentation Leakage Pressure test Zero leaks Test report Signal Loop check 4-20mA Signal log Zero No flow ±0.1% Zero report Flow Known rate ±0.5% Test certificate Documentation Needs

- Installation photos

- Test results

- Configuration data

- Calibration certificates

- Maintenance schedule

Conclusion

Successful flow meter installation requires careful attention to location selection, safety measures, technical configuration, and verification. Following these requirements ensures accurate measurement and reliable operation.

Need expert guidance for your flow meter installation? Contact our technical team for professional support.