Poor grounding can cause erratic readings, signal noise, and complete meter failure in your flow measurement system.

A grounding ring is a conductive metal ring installed between flanges to ensure proper electrical grounding of magnetic flow meters, essential for accurate measurement.

Flow Meter Grounding Ring Components

Let me share what I’ve learned from installing hundreds of magnetic flow meters.

What is the Grounding Ring on a Flowmeter?

Many engineers struggle with understanding the importance of proper grounding in flow measurement.

Grounding rings are metallic conductors that create an electrical connection between the process fluid and the flow meter, ensuring signal stability and measurement accuracy.

Grounding Ring Structure Details

From my extensive field experience:

Grounding Ring Basics

Components and Materials

Component Material Options Purpose Ring Body 316L SS/Hastelloy Conductivity Surface Smooth/Serrated Contact area Thickness 3-6mm Durability Connection Lug/Tab Grounding point Design Features

- Corrosion resistance

- Surface finish

- Contact area

- Material compatibility

Selection Criteria

Application Requirements

- Process fluid

- Temperature range

- Pressure rating

- Chemical compatibility

Installation Considerations

- Pipe size

- Flange type

- Space constraints

- Maintenance access

Proper selection ensures reliability.

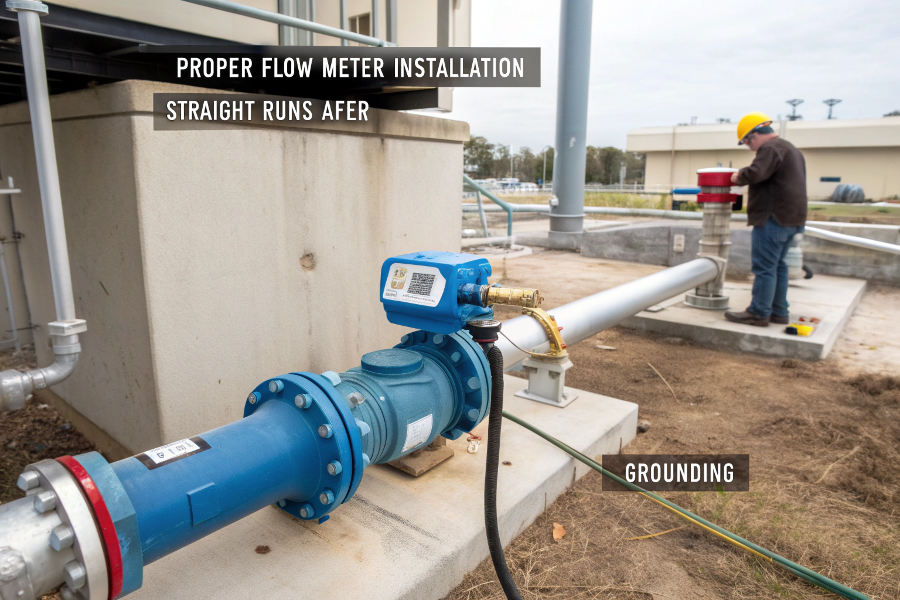

What is the Correct Installation of a Flow Meter?

Incorrect installation leads to measurement errors and premature equipment failure.

Proper flow meter installation requires correct orientation, adequate straight runs, proper grounding, and appropriate gasket selection.

Flow Meter Installation Guidelines

Based on my installation experience:

Installation Guidelines

Key Requirements

Aspect Requirement Purpose Upstream 5-10D straight run Flow profile Downstream 3-5D straight run Stability Orientation Sensor electrodes horizontal Air bubble prevention Grounding Multiple points Signal stability Installation Steps

- Pipe preparation

- Alignment check

- Gasket placement

- Torque sequence

- Ground connection

Best Practices

Installation Verification

- Alignment check

- Leak testing

- Signal verification

- Documentation

Common Pitfalls

- Improper grounding

- Misalignment

- Wrong gaskets

- Inadequate support

Correct installation ensures accuracy.

What is the Purpose of a Grounding Ring?

Signal instability and measurement errors often result from inadequate grounding.

Grounding rings create a reliable electrical path between the process fluid and meter, eliminating noise and ensuring accurate flow measurement.

Grounding Ring Function Diagram

Here’s what I’ve learned:

Grounding Ring Functions

Primary Purposes

Function Benefit Impact Signal Stability Accurate readings Better control Noise Reduction Clear signal Reliable data Reference Potential Stable measurement Consistent results Protection Equipment safety Longer life Technical Benefits

- EMI reduction

- Signal clarity

- Measurement stability

- Equipment protection

Implementation Details

System Requirements

- Proper sizing

- Material selection

- Installation method

- Maintenance access

Performance Factors

- Contact resistance

- Surface condition

- Environmental effects

- Long-term stability

Proper grounding ensures reliability.

Why Does a Magnetic Flowmeter Need Grounding?

Magnetic flow meters often fail due to poor understanding of grounding requirements.

Magnetic flowmeters require proper grounding to establish a stable voltage reference, eliminate electrical noise, and ensure accurate flow measurement.

Magnetic Flow Meter Grounding Diagram

From my troubleshooting experience:

Grounding Requirements

Technical Reasons

Factor Impact Solution Signal Generation Measurement accuracy Proper grounding Noise Elimination Signal quality Multiple grounds Reference Potential Stability Ground rings Safety Personnel protection Ground verification Implementation Methods

- Ground rings

- Grounding electrodes

- Ground straps

- Ground wires

System Integration

Installation Requirements

- Ground point selection

- Connection methods

- Verification testing

- Documentation

Maintenance Needs

- Regular inspection

- Connection cleaning

- Resistance testing

- Preventive maintenance

Proper grounding ensures success.

Conclusion

Proper grounding ring installation and maintenance are crucial for magnetic flow meter performance, requiring careful attention to material selection, installation procedures, and regular maintenance.