Selecting the wrong radar frequency can lead to measurement errors, reduced accuracy, and poor performance in challenging process conditions.

Radar level transmitters typically operate in frequency ranges of 6 GHz, 26 GHz, and 80 GHz, each suited for specific applications and process conditions.

Radar Frequency Ranges Overview

Let me share my experience with different radar frequencies in industrial applications.

What is the Frequency Range of a Radar Sensor?

Process engineers often struggle to choose the right frequency for their application.

Industrial radar sensors operate in microwave frequency bands from 6 GHz to 80 GHz, with common frequencies being 6 GHz, 26 GHz, and 80 GHz.

From my field experience:

Frequency Characteristics

Common Frequencies

Frequency Beam Angle Best For 6 GHz 20-30° Heavy vapors 26 GHz 8-10° General use 80 GHz 3-4° Narrow tanks Application Considerations

- Process conditions

- Tank geometry

- Material properties

- Installation constraints

Performance Impact

Signal Behavior

- Wave propagation

- Reflection characteristics

- Interference patterns

- Resolution capabilities

Environmental Effects

- Vapor penetration

- Temperature influence

- Pressure impact

- Dielectric properties

Understanding these characteristics aids selection.

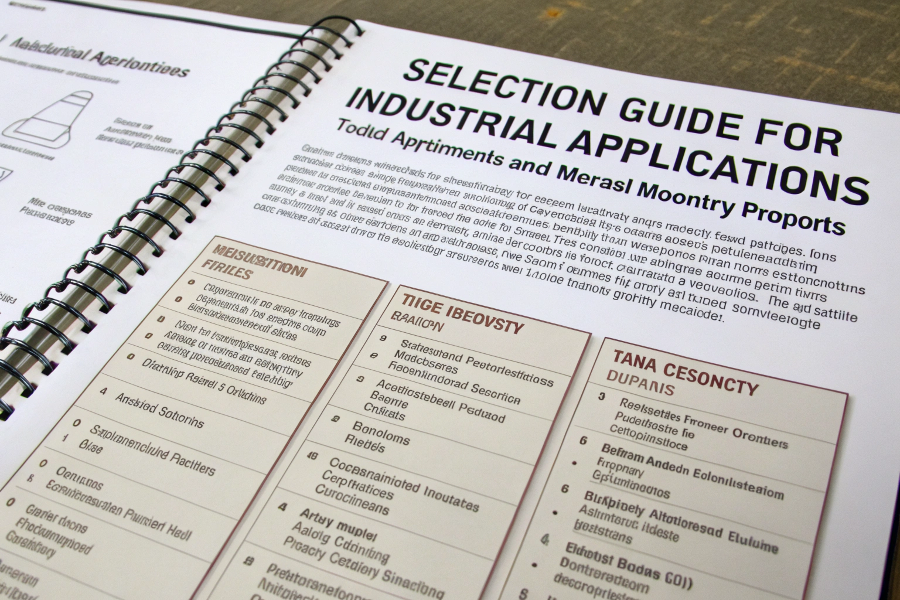

How to Select Radar Level Transmitter?

Choosing the wrong radar transmitter can result in poor performance and wasted investment.

Selection depends on application requirements, process conditions, tank geometry, and material properties. Consider frequency, antenna type, and mounting options.

Radar Selection Guide

Based on my selection experience:

Selection Criteria

Application Requirements

Factor Consideration Impact Material Dielectric Signal strength Process Conditions Reliability Tank Geometry Installation Accuracy Needs Frequency choice Technical Specifications

- Measurement range

- Temperature limits

- Pressure ratings

- Accuracy requirements

Installation Factors

Mounting Considerations

- Available connections

- Nozzle dimensions

- Clearance needs

- Access requirements

Environmental Conditions

- Temperature variations

- Vapor presence

- Dust levels

- Vibration exposure

These factors ensure proper selection.

What are the Limitations of Radar Level Transmitters?

Understanding limitations helps avoid application mistakes.

Radar transmitters can be affected by low dielectric materials, dense vapors, foam, and turbulent surfaces. Installation constraints and cost are also considerations.

Here’s what I’ve learned:

Technical Limitations

Physical Constraints

Limitation Impact Solution Beam angle Dead zone Higher frequency Signal strength Range Larger antenna Resolution Accuracy Better frequency Build-up Performance Special antenna Process Limitations

- Material properties

- Surface conditions

- Process dynamics

- Environmental factors

Application Constraints

Installation Issues

- Mounting restrictions

- Space limitations

- Interference sources

- Access requirements

Operational Challenges

- Maintenance needs

- Calibration demands

- Cost considerations

- Training requirements

Understanding limitations enables proper application.

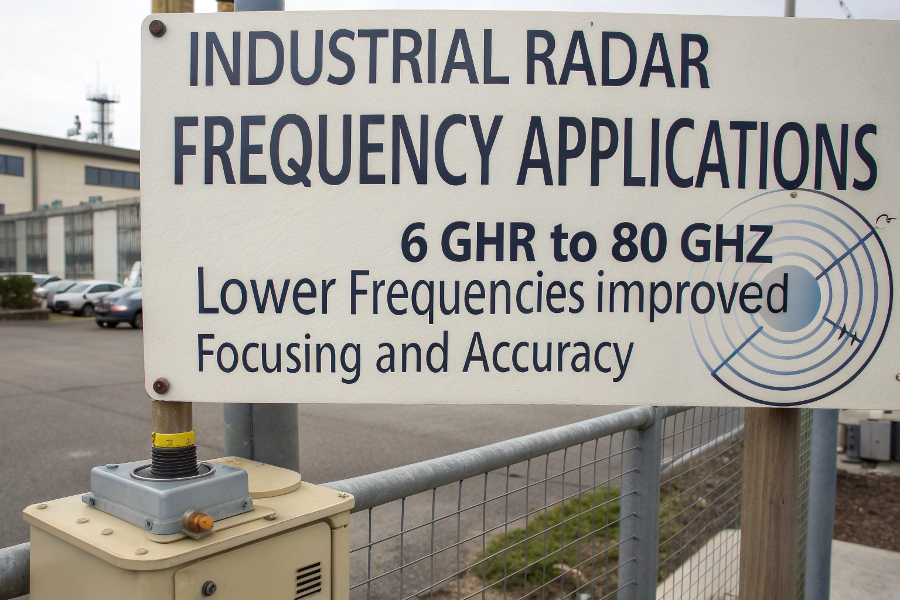

What Frequency Range Does Radar Level Meter Use?

Different frequencies suit different applications and conditions.

Industrial radar uses frequencies from 6 GHz to 80 GHz. Lower frequencies handle vapors better, while higher frequencies offer better focusing and accuracy.

Radar Frequency Applications

From my implementation experience:

Frequency Applications

Frequency Selection

Range Application Advantage 6 GHz Heavy vapor Better penetration 26 GHz General use Good balance 80 GHz Precise measurement Narrow beam Performance Characteristics

- Signal behavior

- Beam properties

- Material interaction

- Measurement accuracy

Application Matching

Process Requirements

- Material type

- Tank conditions

- Accuracy needs

- Installation constraints

Environmental Factors

- Vapor presence

- Temperature range

- Pressure conditions

- Space limitations

Proper frequency selection ensures optimal performance.

Conclusion

Understanding radar frequency ranges is crucial for successful level measurement. The right choice between 6 GHz, 26 GHz, and 80 GHz depends on application requirements and process conditions.