Selecting the wrong turndown ratio can lead to costly measurement errors and equipment inefficiency.

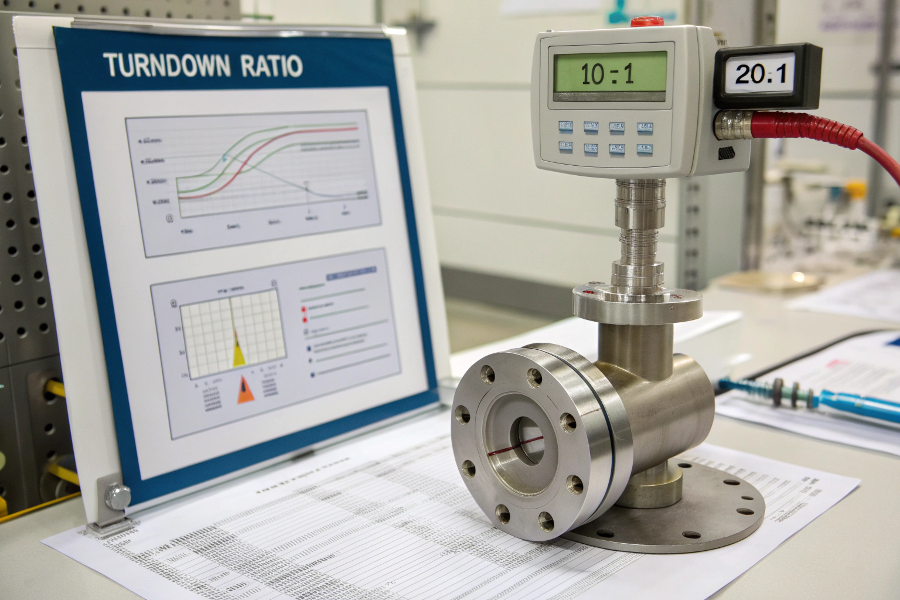

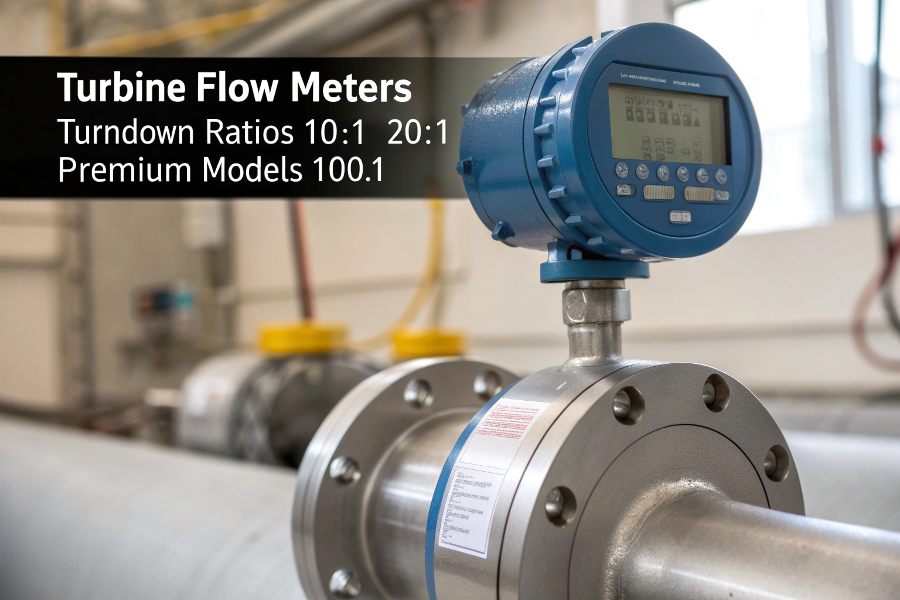

A turbine flow meter’s turndown ratio typically ranges from 10:1 to 20:1, representing the ratio between maximum and minimum measurable flow rates. This specification is crucial for ensuring accurate measurements across varying flow conditions.

Turndown Ratio Visualization

Let’s explore how turndown ratio impacts flow measurement accuracy and equipment selection.

What Is the Turndown Ratio of a Turbine Flow Meter?

Choosing the right turndown ratio affects measurement reliability.

Turbine flow meters generally offer turndown ratios between 10:1 and 20:1, though premium models can achieve up to 100:1. The specific ratio depends on fluid properties, meter design, and application requirements.

Turbine Meter Range Comparison

From my experience working with various installations, turndown ratio selection depends on several factors:

Design Considerations

Bearing Type

- Ball bearings: Higher turndown potential

- Sleeve bearings: Lower turndown range

Rotor Design

- Blade angle

- Material selection

- Mass distribution

Application Factors

- Fluid viscosity range

- Operating temperature

- Flow profile stability

- Required accuracy

Understanding these elements helps in selecting the optimal turndown ratio for specific applications.

What Is Turndown of Flowmeter?

Grasping the turndown concept helps optimize meter selection.

Turndown represents a flow meter’s ability to measure accurately across different flow rates. It’s expressed as the ratio between maximum and minimum measurable flows while maintaining specified accuracy.

Flowmeter Range Illustration

Here’s how I explain turndown to my clients:

Practical Example

- Maximum flow: 100 gallons per minute

- Minimum flow: 10 gallons per minute

- Resulting turndown: 10:1

Impact Factors

Measurement Technology

- Turbine meters

- Magnetic meters

- Ultrasonic meters

- Coriolis meters

Application Requirements

- Process variations

- Accuracy needs

- Cost considerations

This understanding ensures appropriate meter selection for specific applications.

What Does 30% Turndown Mean?

Understanding percentage turndown aids in operational planning.

A 30% turndown means the meter can measure down to 30% of its maximum flow rate while maintaining specified accuracy. For example, a meter rated for 100 GPM maximum flow can measure accurately down to 30 GPM.

30% Turndown Visualization

Let me break down the implications:

Practical Applications

- Process control flexibility

- Energy efficiency

- Equipment sizing

- Cost optimization

Operating Considerations

Flow Range Management

- Normal operation points

- Peak requirements

- Minimum flow needs

Performance Impact

- Accuracy at low flows

- Energy consumption

- Maintenance needs

This knowledge helps optimize system design and operation.

What Does the Turndown Ratio Indicate?

The turndown ratio reveals crucial operational capabilities.

Turndown ratio indicates a meter’s versatility in measuring different flow rates accurately. A higher ratio means greater flexibility in handling flow variations while maintaining measurement accuracy.

Turndown Performance Indicators

Based on my field experience, here’s how turndown ratio affects operations:

Performance Indicators

Measurement Range

- Maximum flow capacity

- Minimum reliable flow

- Accuracy bands

Operational Flexibility

- Process variability handling

- Control system integration

- Energy efficiency

Selection Criteria

- Process requirements

- Cost considerations

- Maintenance needs

- Future expansion plans

Understanding these aspects ensures optimal meter selection and operation.

Conclusion

Turndown ratio is crucial for turbine flow meter performance, affecting measurement accuracy and operational flexibility. Understanding this specification helps select the right meter for specific applications and ensures reliable measurements across varying flow conditions.