Understanding the mechanics behind turbine flow meters is essential for effective implementation.

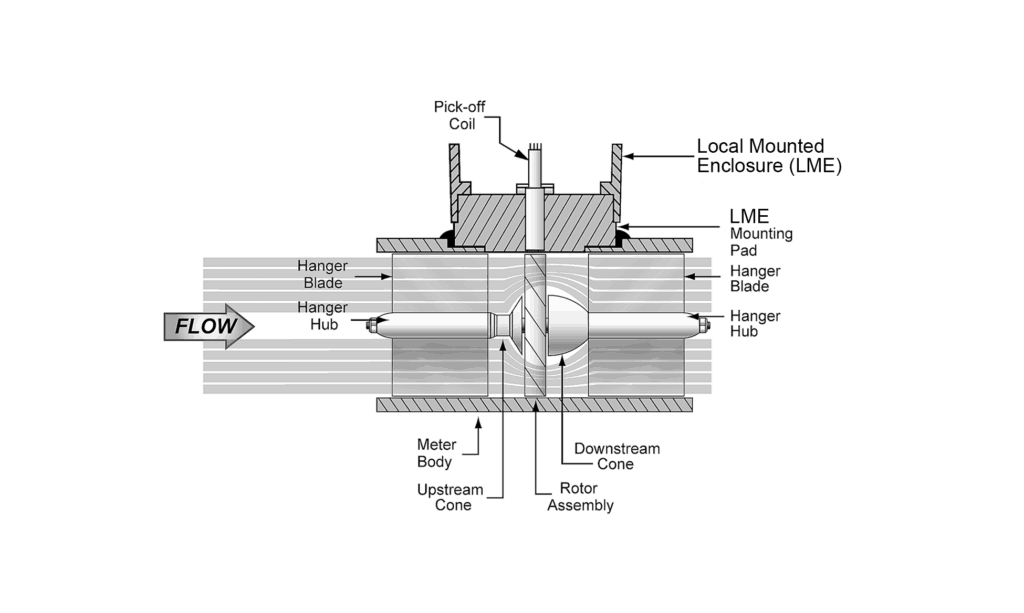

The working principle of a turbine flow meter is based on the movement of a rotor. As fluid flows through the meter, it spins the turbine blades. The rotational speed correlates with the flow rate, allowing measurement based on how quickly the turbine spins.

Circular Motion in Turbine Meter

Comprehending these mechanics assists in the selection and proper use of turbine flow meters.

What Are the Disadvantages of Turbine Flow Meter?

Knowing potential drawbacks helps in sensible device selection.

Turbine meters are less effective with low flow rates and susceptible to blockage by impurities. Their moving parts offer wear risks, necessitating periodic maintenance. Disturbances in flow profiles can affect measurement accuracy, making them less suited for unstable environments.

Recognizing these limitations guides intelligent decisions for specific applications and environments.

What Is the Working Principle of Flowmeter?

Diverse flow meters have unique operating mechanisms.

Most flow meters function by translating movement or changes within a fluid to measurable data. Examples include pressure changes within a differential pressure meter, ultrasonic waves in ultrasonic meters, and electromagnetic effects in magnetic flow meters. Each principle caters to particular measurement needs.

Understanding varied principles enables selecting the best flow meter for specific applications involving different fluids.

What Are the Applications of Turbine Flowmeter?

Exploring usage scopes enhances understanding of application areas.

Turbine flow meters are useful in industries like water treatment, oil and gas, and chemical processing. Their simple design and high accuracy suit applications requiring detailed monitoring of fluid movement under stable flow conditions without impurities.

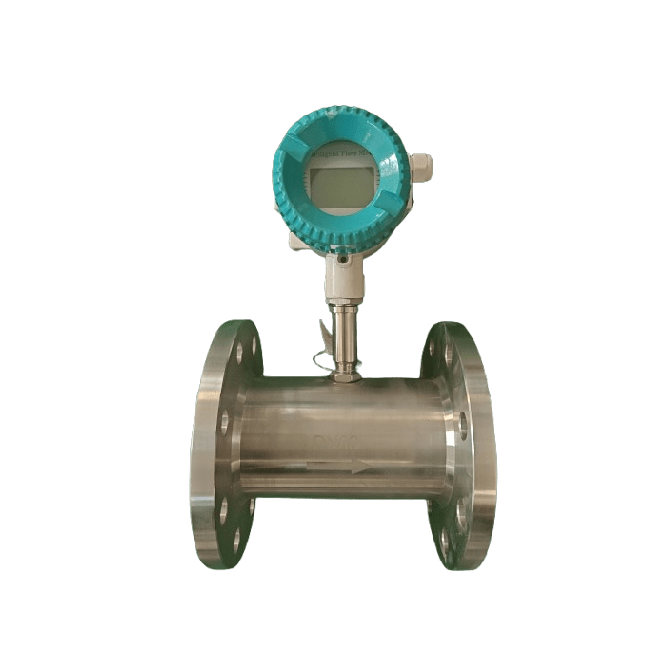

Turbine Flow Meter

Selecting turbine meters requires examining environmental conditions to ensure optimal long-term performance.

What Is the Life Expectancy of a Turbine Flow Meter?

Understanding longevity impacts investment decisions.

The typical life expectancy of a turbine flow meter ranges from 5 to 10 years. Factors affecting lifespan include fluid type, installation environment, and maintenance frequency. Regular upkeep can extend operational longevity and ensure sustained accuracy.

Applying consistent upkeep and selecting suitable environments maintains performance over a longer period.

Conclusion

The turbine flow meter’s principle involves turbine rotation to measure flow rate. Though it faces challenges like wear and blockages, understanding its benefits in varied applications helps draw its potential lifespan closer to the 10-year mark with appropriate care.