Incorrect turbine flow meter installation can result in inaccurate measurements, affecting operations significantly.

For optimal results, install the turbine flow meter with at least 10 pipe diameters of straight pipe upstream and 5 diameters downstream. Also, verify the K-factor post-installation to ensure measurement accuracy.

Turbine Flow Meter

Proper installation practices, along with rigorous post-installation checks, ensure that your turbine flow meter delivers reliable performance and longevity.

What Is the Rule of Thumb for Flow Meter Installation?

Improper pipe runs can cause measurement errors and inefficiencies.

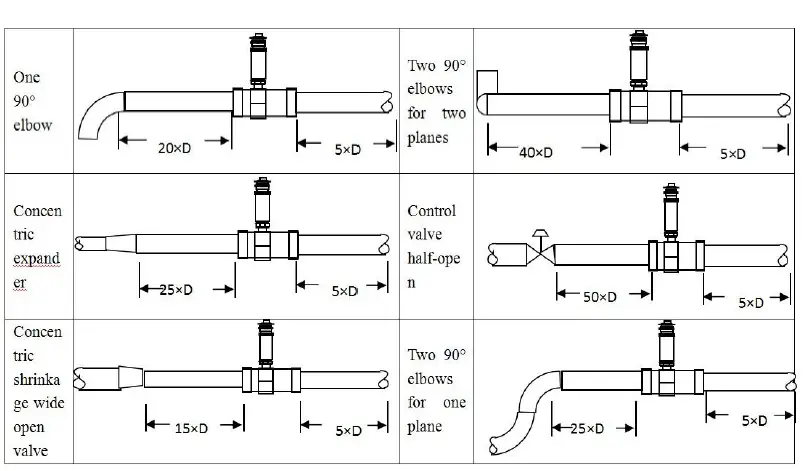

The rule of thumb for installing flow meters is to have a minimum straight run of 10 pipe diameters upstream and 5 downstream of the meter. This ensures a fully developed flow profile and minimizes errors caused by flow disturbances.

Pipe Installation Requirements

Accurate flow measurement depends on correcting for any disturbances caused by elbows, valves, or other fittings close to the meter. Correct alignment and pipe condition are also crucial.

What Is the K Factor of a Turbine Flowmeter?

The K-factor is critical for accurate flowmeter readings, influencing process outcomes.

The K-factor is the calibration factor of a turbine flowmeter, representing the number of pulses generated per unit volume of fluid passing through the meter. It is crucial for converting frequency signals into actual flow rate.

Field Verification Process

Factors such as fluid characteristics, meter wear, and installation conditions can alter the K-factor, necessitating periodic recalibration for accuracy.

How Should a Flow Meter Be Installed?

Proper installation is vital to prevent flow meter failure and ensure accurate measurement.

A flow meter should be installed with correct alignment and secure mounting, avoiding excessive stress on the meter body. Proper electrical connections and grounding are essential to maintain data integrity and prevent signal interference.

Following manufacturer specifications and guidelines during installation enhances the efficiency and lifespan of the flow meter.

What Is the Protocol for Turbine Flow Meter Calibration?

Calibration ensures the accuracy and reliability of flow meter readings over time.

Flow meter calibration involves verifying and adjusting the meter’s K-factor under controlled conditions to match factory settings or process-specific requirements. Regular calibration offsets measurement drift caused by wear or installation conditions.

Commissioning Steps

Adhering to a regular calibration schedule is essential in maintaining flow meter precision and ensuring process control efficacy.

Conclusion

Adhering to installation guidelines with a sufficient straight pipe run, verifying the K-factor, and following proper installation and calibration protocols is crucial for ensuring reliable turbine flow meter performance and accuracy.