Plant operators frequently underestimate vortex meter pressure drops, risking flow capacity reduction and increased pump costs by 5-10%. Small pressure losses accumulate into significant energy expenses.

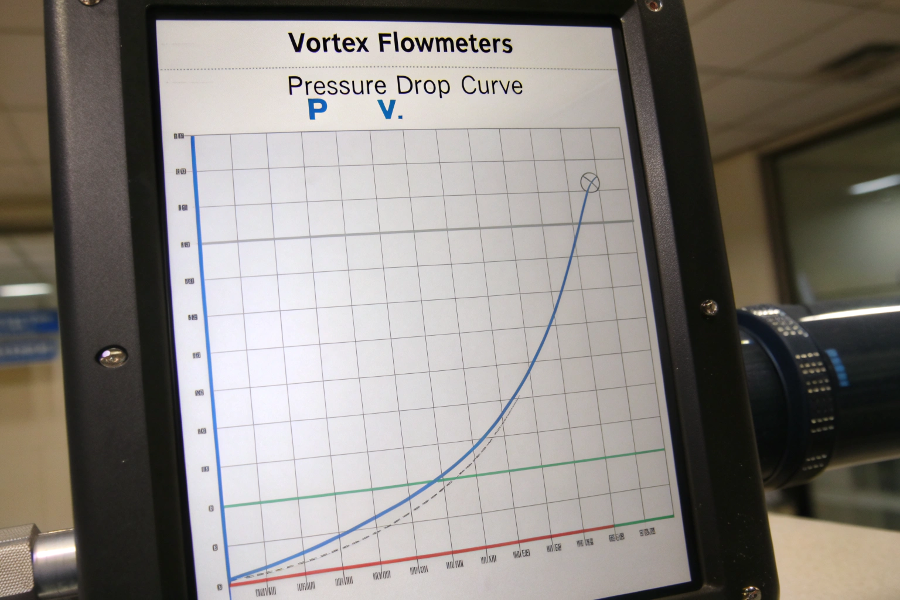

Vortex flowmeters typically create 0.15-0.3 bar (2-4 psi) pressure drop at maximum flow, varying based on meter size, design, and flow rate. This is lower than orifice plates but higher than magnetic flow meters, with pressure loss increasing exponentially (not linearly) with flow velocity (ΔP ∝ v²).

Vortex Meter Pressure Profile

Pressure drop directly impacts operational costs across three key areas: energy consumption, pump sizing, and flow capacity. The following sections detail pressure loss characteristics across different meter types.

What Is the Pressure Drop on a Vortex Flowmeter?

Four factors determining vortex meter pressure loss:

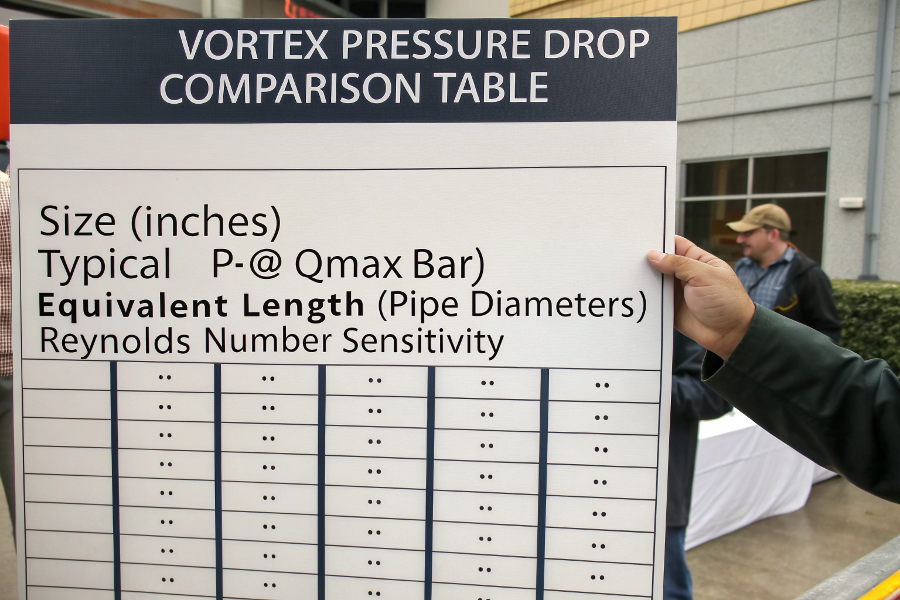

Vortex Pressure Drop Comparison Table

| Size (inches) | Typical ΔP @ Qmax (bar) | Equivalent Length (pipe diameters) | Reynolds Number Sensitivity |

|---|---|---|---|

| 1" | 0.30 | 20D | Highest |

| 2" | 0.25 | 18D | High |

| 4" | 0.20 | 15D | Medium |

| 6" | 0.15 | 12D | Low |

| 8" | 0.12 | 10D | Lowest |

Engineering Considerations

Design Elements Affecting ΔP

- Shedder bar thickness (+15% per 1mm)

- Body internal finish (±5% change)

- Flange vs wafer design (3-7% difference)

- Upstream conditioning (+8-12%)

Flow Rate Relationship

- 50% flow: 25% of Qmax ΔP

- 75% flow: 56% of Qmax ΔP

- 100% flow: Full ΔP

- 120% flow: 144% ΔP (exponential)

Material Impact

- Stainless steel: Standard

- Hastelloy: +2-3%

- Lined bodies: -5-8%

Vortex ΔP vs Flow Rate

Calculating Energy Costs

- Formula: kW = (ΔP × Q) ÷ (3600 × η)

- Example (100m³/h water @ 0.2 bar):

- (0.2 × 100) ÷ (3600 × 0.8) = 0.00694 MW

- Annual cost @ $0.10/kWh: $6,082

What Is the Pressure Drop in a Flow Meter?

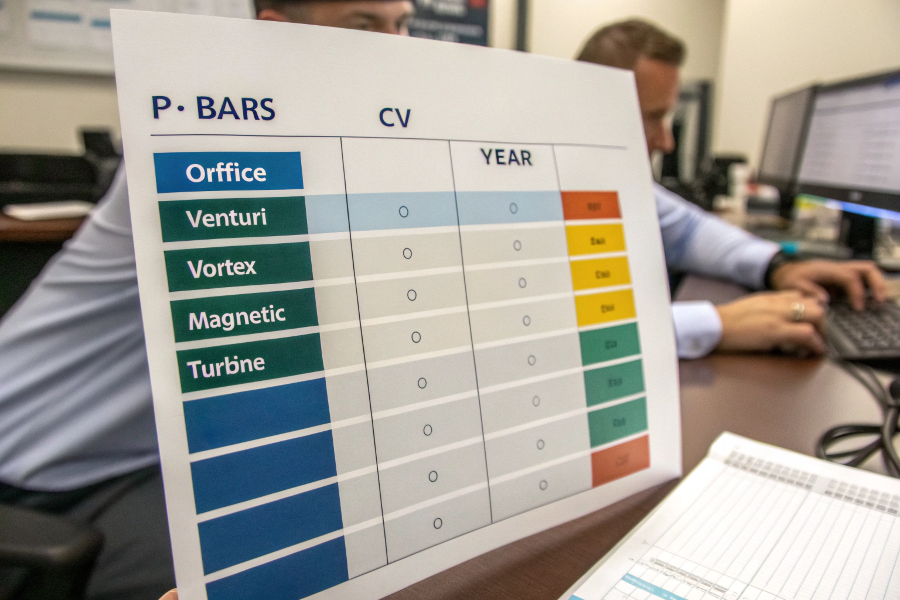

Five meter technologies compared:

Flow Meter Pressure Drop Benchmark

| Meter Type | ΔP Range @ Qmax (bar) | Coefficient (Cv) | Energy Cost per Year* |

|---|---|---|---|

| Orifice | 0.5-1.5 | Low | $$$$ |

| Venturi | 0.1-0.4 | High | $$ |

| Vortex | 0.15-0.3 | Medium | $$$ |

| Magnetic | 0.02-0.1 | Very High | $ |

| Turbine | 0.25-0.5 | Medium-High | $$$ |

*Based on 8,760 hrs @ 100m³/h water

Selection Criteria

Process Requirements

- Custody transfer: Accept higher ΔP

- Pump capacity: Check NPSH margin

- Viscous fluids: Avoid high ΔP meters

Economic Factors

- Electricity unit cost

- Operating hours

- Pump efficiency

Maintenance Trade-offs

- High ΔP = More cleaning

- Low ΔP = Higher meter cost

- Balanced approach needed

Technology ΔP Ranges

Rules for ΔP Reduction

- Acceptable Methods:

- Oversize meter (25% rule)

- Use venturi-style designs

- Select full-bore options

- Improve pipe routing

- Upgrade pump capacity

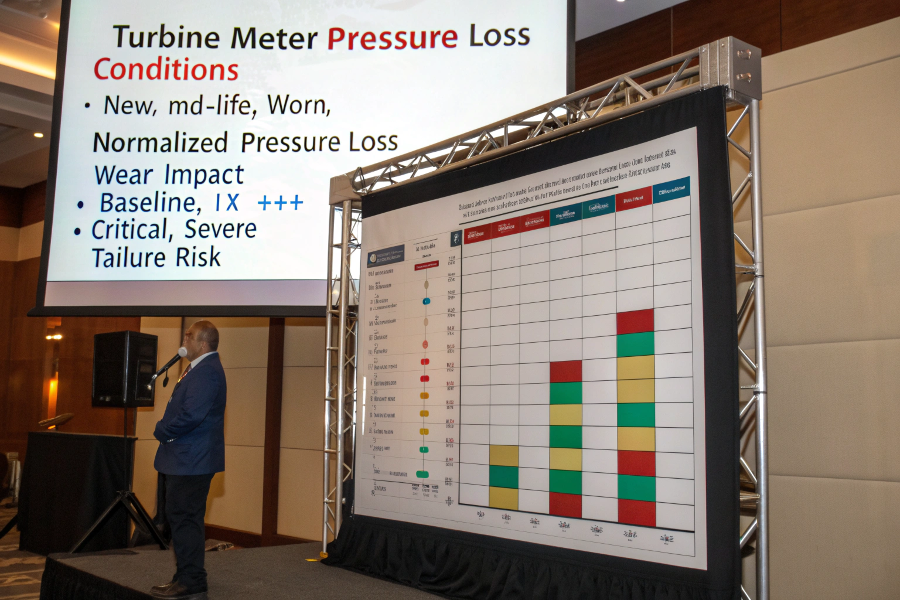

What Is the Pressure Drop on a Turbine Flowmeter?

Three turbine meter pressure scenarios:

Turbine Meter Pressure Loss Data

| Condition | ΔP Normalized to Vortex | Wear Impact | Viscosity Effect |

|---|---|---|---|

| New | 1.2x | Baseline | Critical |

| Mid-life | 1.5x | ++ | Severe |

| Worn | 2.0x | +++ | Failure risk |

Operational Impacts

Bearing Drag Effects

- Clean fluid: 0.25 bar

- Contaminated: +40-60%

- Worn bearings: +100%

Flow Rate Sensitivity

- Linear ΔP vs Q (unlike vortex)

- 50% flow = 50% ΔP

- 25% flow = 25% ΔP

Size Considerations

- Small turbines: Highest ΔP

- 6"+ sizes: Comparable to vortex

- Bypass designs: Lower ΔP

Turbine ΔP Progression

Maintenance Warning Signs

- Increasing ΔP Indicates:

- Bearing degradation

- Blade deposits

- Magnetic drag

- Shaft misalignment

- Fluid contamination

What Is the Pressure Drop in Air Flow?

Four gas-specific pressure considerations:

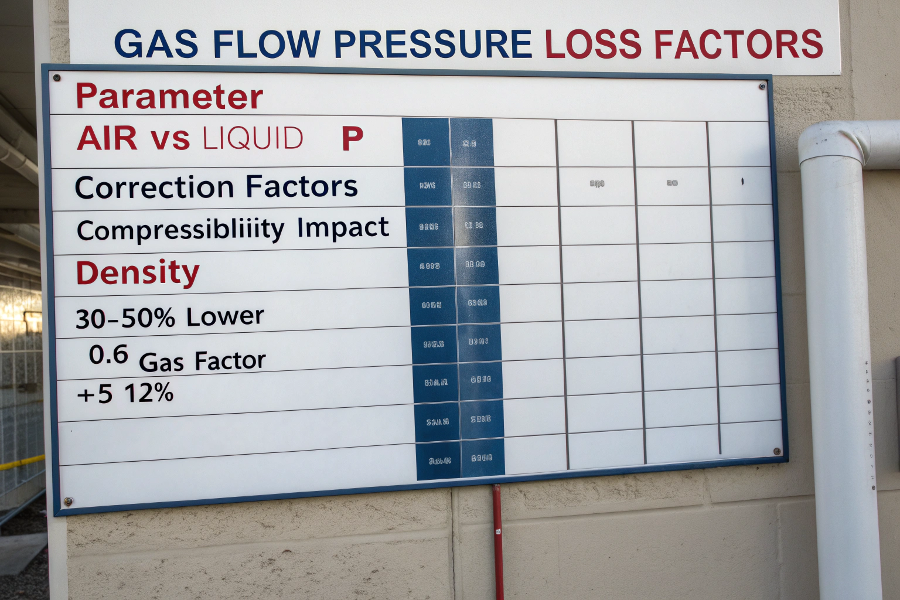

Gas Flow Pressure Loss Factors

| Parameter | Air vs Liquid ΔP | Correction Factors | Compressibility Impact |

|---|---|---|---|

| Density | 30-50% lower | ×0.6 gas factor | +5-12% effect |

| Velocity | 3-10x higher | v² dominates | Minor |

| Viscosity | Negligible | None | None |

| Temperature | Inverse relation | 1/√T absolute | -1%/10°C |

Calculation Methods

Modified Bernoulli Equation

ΔP = K × (ρ × v²) ÷ 2

Where:

K = Meter K-factor

ρ = Density (kg/m³)

v = Velocity (m/s)Practical Shortcut

Air ΔP ≈ 0.6 × water ΔP

(at same velocity)Altitude Adjustments

+1.2%/100m elevation

(up to 5,000m)

Gas Pressure Loss

Compressed Air Costs

- Typical System Losses:

- Meters: 0.1-0.3 bar

- Filters: 0.05-0.15 bar

- Dryers: 0.2-0.5 bar

- Piping: 0.01 bar/10m

- Total: Often 1+ bar

Conclusion

Vortex flowmeters generate moderate 0.15-0.3 bar pressure drops – higher than magmeters but lower than turbines or orifice plates. Gas service reduces ΔP by 40% versus liquids, while viscosity and meter wear dramatically increase losses in turbine meters. Proper ΔP management requires balancing measurement accuracy against energy costs, with oversized vortex meters often providing the best compromise between performance and