Getting flow measurement wrong in small pipes can cost thousands in errors. The right meter prevents these mistakes while maximizing performance.

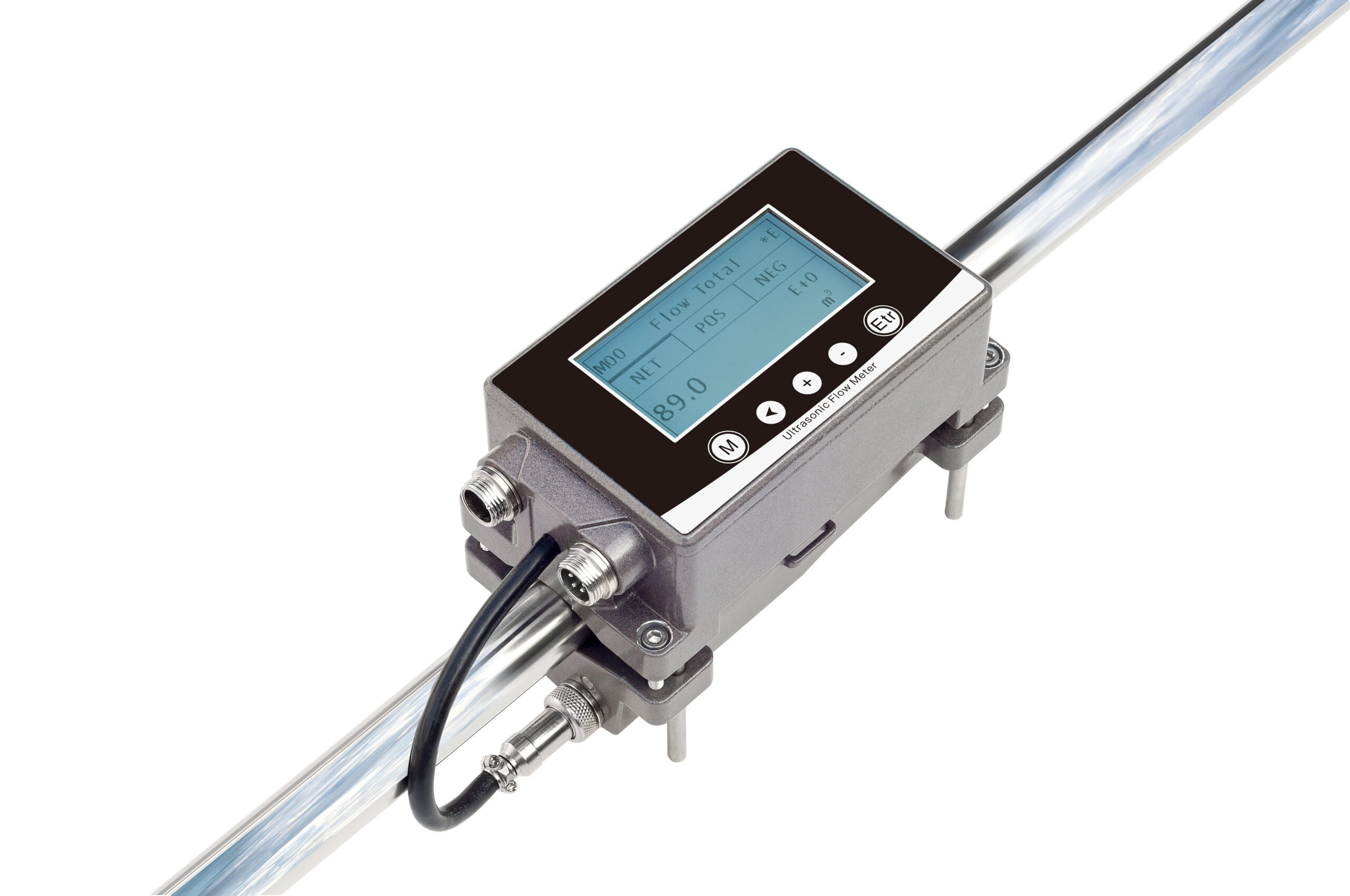

Selecting the correct flow meter for small pipes (DN10-DN50) requires matching 6 key factors: pipe diameter, flow range (0.1-10 m/s), fluid type (clean/dirty), accuracy needs (±0.5-5%), pressure drop tolerance (0-5 bar), and installation constraints (straight runs, vibration). Ultrasonic meters often win for 6-50mm pipes due to their non-invasive nature and ±1% accuracy.

Flow Meter Selection Factors

The stakes are higher with small pipes where installation effects multiply. Here’s what really matters when choosing.

How Do I Choose a Flow Meter Size?

Avoid the 3 most common sizing mistakes:

Small-Pipe Selection Matrix

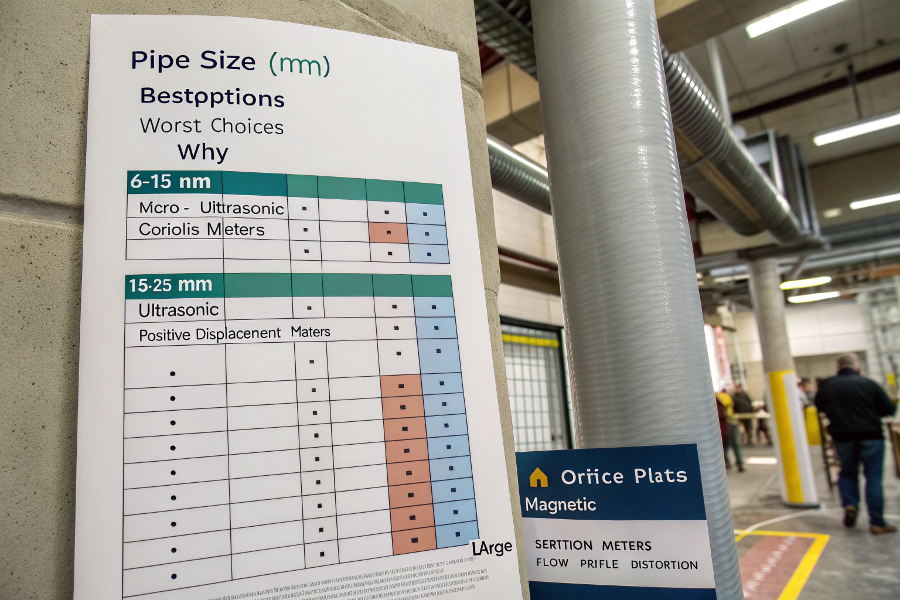

| Pipe Size (mm) | Best Options | Worst Choices | Why? |

|---|---|---|---|

| 6-15 | Micro-ultrasonic, Coriolis | Turbine, Vortex | Space constraints |

| 15-25 | Ultrasonic, Positive Displace | Orifice Plate | Accuracy needs |

| 25-50 | Ultrasonic, Magnetic | Large Insertion Meters | Flow profile distortion |

Critical Size Considerations

- Minimum bore clearance – Leave 2mm gap minimum

- Wetted part compatibility – Material resistance

- Sensor head size – Fits available pipe space

- Process connections – Matching thread/Flange

- Future pipe changes – Adjustable range

Pipe-to-Meter Matching

Proven Selection Process

- Measure exact ID (not nominal size)

- Calculate Reynolds number

- Determine minimum/max flow rates

- Verify pressure ratings

- Check access for installation

- Confirm future maintenance access

- Review industry standards (ASME/ISO)

What Are the Factors to Be Considered for Selection of Right Type of Flow Meter?

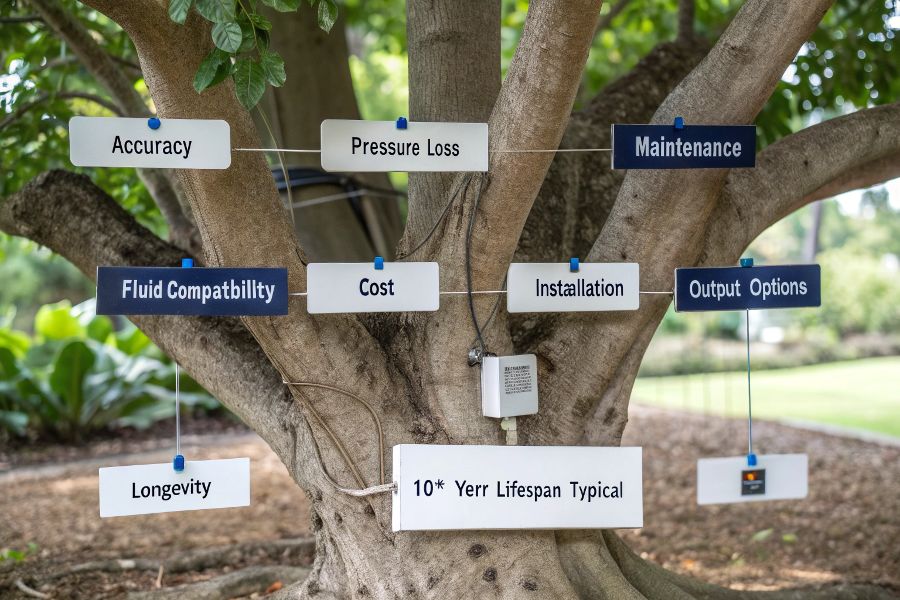

The 8 decision drivers for small pipes:

Priority Factors in Selection

| Factor | Weight (1-10) | Ultrasonic Advantage |

|---|---|---|

| Accuracy | 9 | ±0.5-1% with calibration |

| Pressure Loss | 8 | Nearly zero |

| Maintenance | 7 | No moving parts |

| Fluid Compatibility | 6 | Works with most clean liquids |

| Cost | 5 | Mid-range pricing |

| Installation | 4 | Clamp-on versions available |

| Output Options | 3 | Analog/digital/bus ready |

| Longevity | 2 | 10+ year lifespan typical |

Fluid-Specific Considerations

- Conductivity (for mag meters)

- Viscosity changes

- Particle content

- Gas bubbles

- Temperature swings

- Chemical aggressiveness

Selection Flowchart

Small-Pipe Tradeoffs

- Accuracy vs. Cost – Coriolis vs. ultrasonic

- Pressure Drop vs. Reliability – PD vs. turbine

- Installation Ease vs. Performance – Clamp-on vs. inline

- Maintenance vs. Initial Cost – Mag vs. ultrasonic

How Many Pipe Diameters for a Flow Meter?

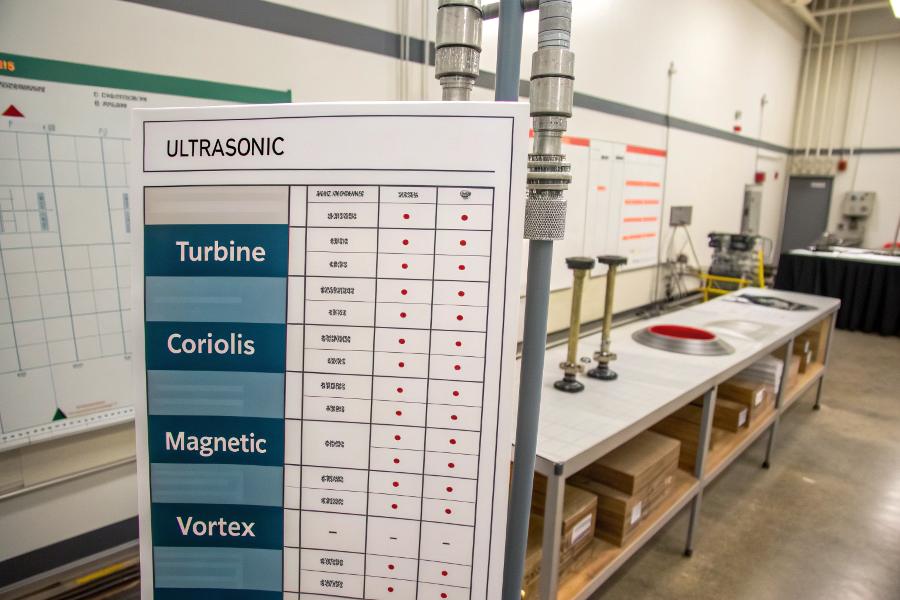

Straight-run requirements vary by technology:

Small-Pipe Installation Distances

| Meter Type | Upstream (Pipe Diameters) | Downstream (Pipe Diameters) | Notes |

|---|---|---|---|

| Ultrasonic | 10D | 5D | Better with flow conditioners |

| Turbine | 15D | 5D | Highly sensitive |

| Coriolis | 0D | 0D | Profile independent |

| Magnetic | 5D | 3D | Conductivity dependent |

| Vortex | 20D | 5D | Needs clean fluid |

Installation Space Needs

When Space is Limited

- Use flow straighteners (reduces to 5D)

- Install conditioning orifice plates

- Choose profile-independent meters

- Select multi-path ultrasonic

- Consider Coriolis despite cost

Special Small-Pipe Cases

- Booster pump discharge (turbulent)

- Heat exchanger loops (temperature)

- Dosing systems (pulsating)

- Sampling lines (low flow)

- Recirculation branches (variable)

Why Is Flow Measurement Important?

Small pipes carry big consequences:

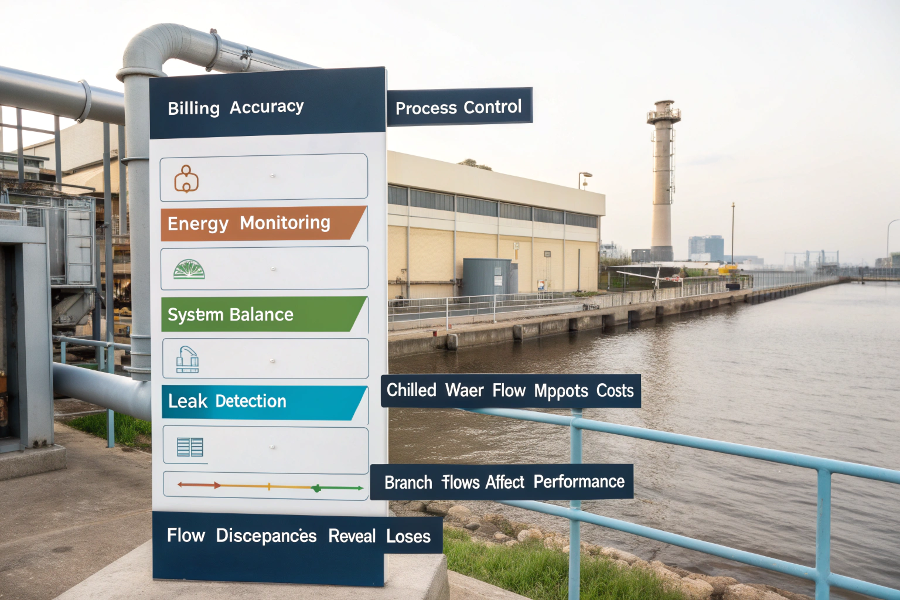

Impact Areas in Industrial Applications

- Billing Accuracy – ±1% error = $10k/year in chemicals

- Process Control – Reactor feed precision affects quality

- Energy Monitoring – Chilled water flow impacts costs

- System Balance – Branch flows affect performance

- Leak Detection – Flow discrepancies reveal losses

Measurement Significance

Small-Pipe Measurement Benefits

- Precise additive dosing

- Miniature process monitoring

- Compact system balancing

- Micro-leak identification

- Lab-scale accurate control

- Compact equipment testing

Regulatory Requirements

- ISO 9001 quality systems

- EPA reporting needs

- Safety interlock triggers

- Energy audit compliance

- Water stewardship standards

Conclusion

Choosing the right flow meter for small pipes (6-50mm) demands careful consideration of size constraints, fluid properties, and accuracy needs. Ultrasonic technology typically offers the best balance of performance and practicality for these challenging applications, provided proper installation guidelines are followed. With small pipe measurements often critical to process success, investing in the right measurement solution prevents costly errors and operational headaches.