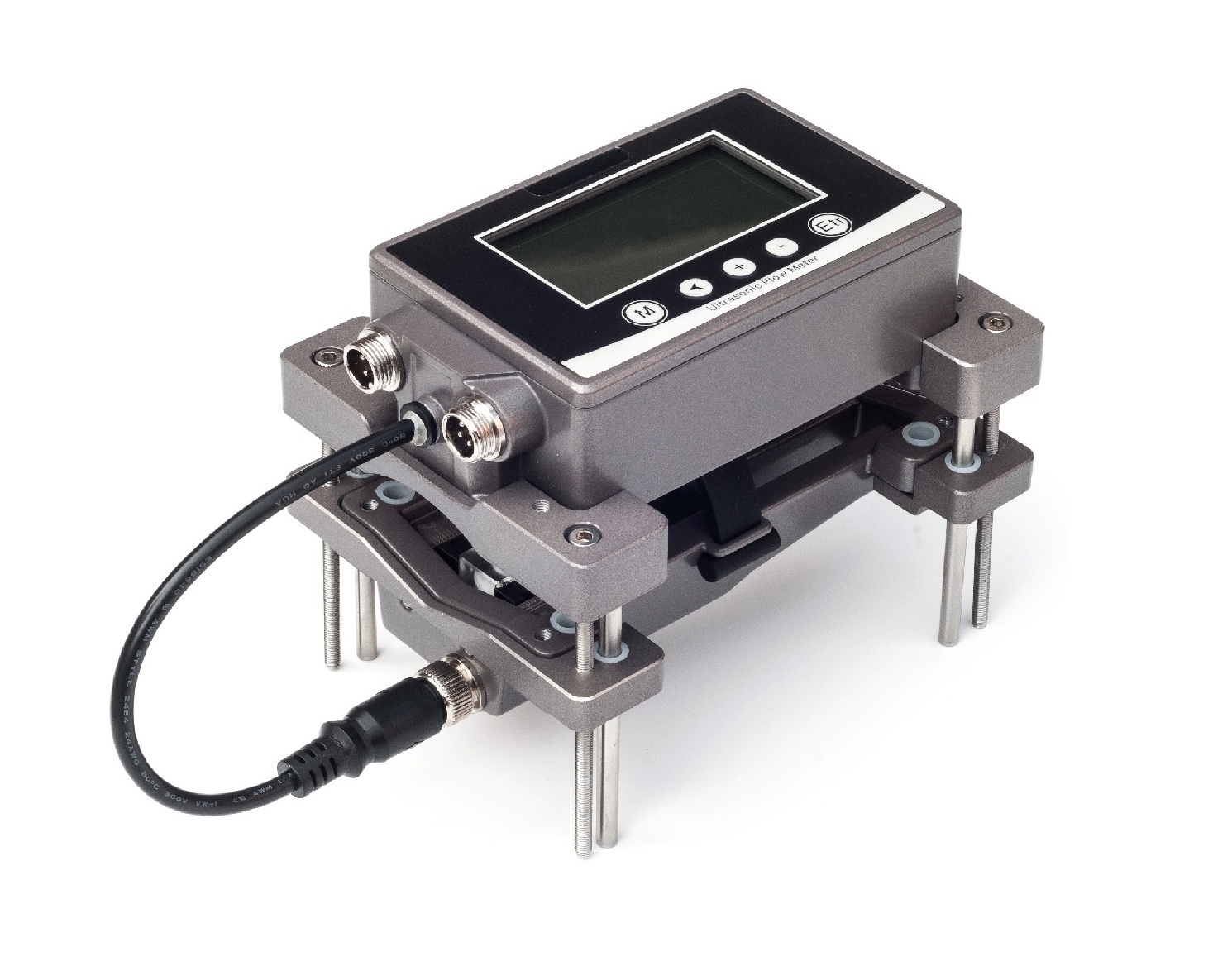

Struggling with flow measurement in pipes under 25mm diameter? Conventional flow meters often fail in small pipes, but modern ultrasonic technology delivers remarkable precision where others can’t.

Ultrasonic flow meters overcome small pipe challenges using high-frequency (1-5MHz) transducers and advanced signal processing, achieving ±0.5-1% accuracy in diameters as small as 6mm when properly installed. While sensitive to bubbles and requiring precise alignment, they outperform mechanical meters in bi-directional flow and no-pressure-drop applications. Two main types (transit-time and Doppler) serve different fluid conditions.

Ultrasonic Measurement in Tight Spaces

Understanding both capabilities and limitations ensures optimal performance in constrained piping systems. Let’s examine the critical factors.

What Are the Limitations of Ultrasonic Flowmeters in Small Diameter Systems?

Key technical constraints below DN25:

Small-Pipe Specific Challenges Comparison

| Limitation | Impact at DN25 | Impact at DN100 | Mitigation Strategy |

|---|---|---|---|

| Signal strength | Severe | Minor | Higher frequency transducers |

| Reflection noise | 3x worse | Normal | Anti-noise algorithms |

| Alignment sensitivity | 0.1° = 2% err | 1° = 1% err | Precision machined holders |

| Temperature effects | 2x impact | Standard | Integrated compensation |

Practical Workarounds

- Inline wetted transducers – Eliminate pipe wall effects

- Multi-reflection paths – Increase effective path length

- High-frequency bursts – Improve signal penetration

- Calibration adjustments – Compensate for small-pipe effects

Technical Constraints Visualized

When Alternative Meters Perform Better

- Highly aerated fluids (>5% gas)

- Slurries with heavy particulates

- Non-conductive liquids (oils)

- Pipes with thick internal linings

What Is the Uncertainty of the Ultrasonic Flow Meter in Small Pipes?

Accuracy metrics across pipe sizes:

Typical Performance Metrics

| Pipe Size | Optimal Accuracy | Typical Accuracy | Worst-Case Accuracy |

|---|---|---|---|

| DN6-DN10 | ±1.0% | ±1.5% | ±3.0% |

| DN15-DN25 | ±0.75% | ±1.25% | ±2.5% |

| DN40-DN50 | ±0.5% | ±1.0% | ±2.0% |

Factors Affecting Uncertainty

- Fluid properties – Density, viscosity, purity

- Installation quality – Straight runs, alignment

- Signal processing – Advanced algorithms reduce errors

- Temperature stability – Thermal expansion effects

Measurement Uncertainty Ranges

Improving Accuracy in Tight Spaces

- Triple-check inner diameter measurements

- Use manufacturer-specific calibration files

- Implement temperature-stable mounting

- Perform wet calibrations at operating conditions

- Select models with diagnostics capabilities

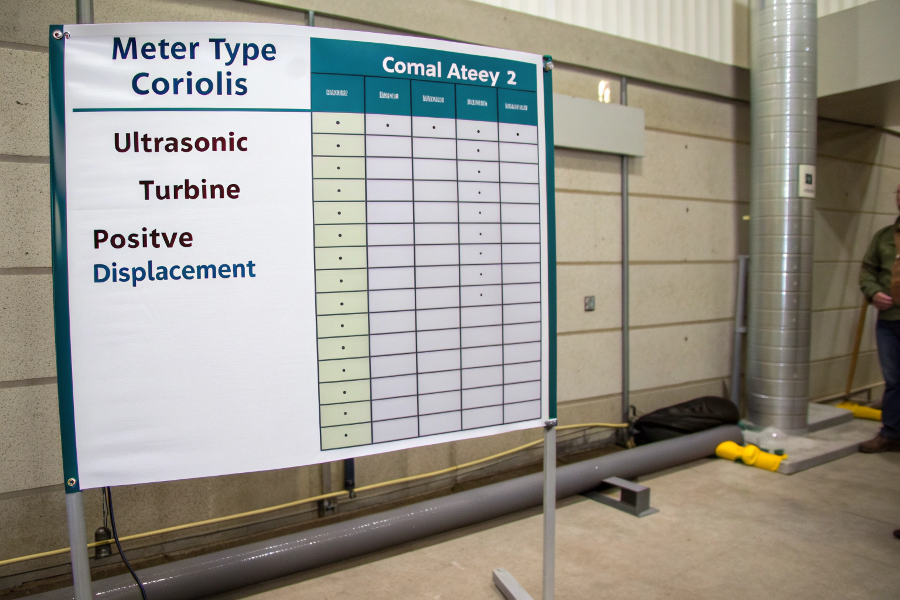

What Is the Most Accurate Flow Meter Type for Small Pipes?

Technology comparison for precision:

Small-Pipe Accuracy Comparison

| Meter Type | Best Case Accuracy | Typical Accuracy | Small-Pipe Suitability |

|---|---|---|---|

| Coriolis | ±0.1% | ±0.2% | Excellent (down to DN4) |

| Ultrasonic (transit) | ±0.5% | ±1.0% | Good (down to DN8) |

| Turbine | ±0.25% | ±0.5% | Fair (down to DN15) |

| Positive displacement | ±0.2% | ±0.5% | Poor (min DN20) |

When to Choose Ultrasonic Anyway

- Bi-directional flow needs – Zero additional error

- Pressure drop concerns – No obstruction

- Maintenance access issues – Non-invasive options

- Multi-variable measurements – Flow + temperature

Precision Benchmarking

Emerging Ultrasonic Advantages

- Self-diagnosing algorithms

- Wireless verification tools

- Integrated process validation

- Predictive maintenance features

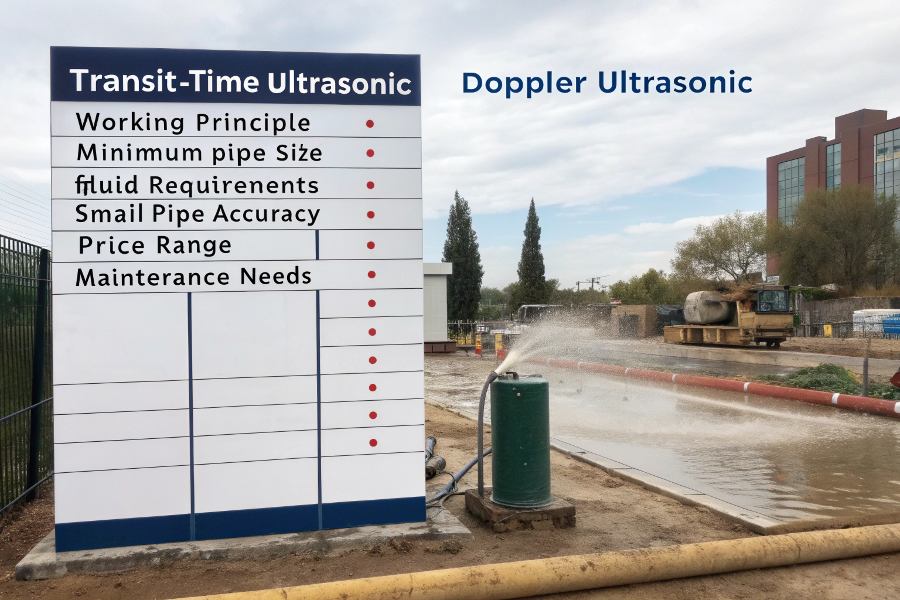

Which Two Types of Ultrasonic Flow Meters Are Commonly in Use?

Operational comparison:

Transit-Time vs. Doppler Characteristics

| Parameter | Transit-Time Ultrasonic | Doppler Ultrasonic |

|---|---|---|

| Working Principle | Measures time difference | Detects frequency shift |

| Minimum Pipe Size | DN8 (specialized) | DN50 (effective) |

| Fluid Requirements | Clean, homogeneous liquids | Contains reflectors |

| Small-Pipe Accuracy | ±0.5-1.5% | Not recommended below DN50 |

| Price Range | $$$$ | $$$ |

| Maintenance Needs | Low | Moderate |

Technology Differences

Specialized Ultrasonic Variants

- Hybrid meters – Combined transit-time/Doppler

- Multi-path designs – Improved profile compensation

- Clamp-on portable – Temporary verification

- Sanitary models – Pharmaceutical grade

Selection Criteria for Small Pipes

- Fluid conductivity/cleanliness

- Available straight pipe runs

- Temperature/pressure range

- Required accuracy level

- Maintenance capabilities

Optimizing Small-Pipe Ultrasonic Performance

Installation Best Practices

- Proper coupling – Use specialized gels for small pipes

- Precise spacing – Millimeter matters in DN15 pipes

- Pipe preparation – Remove coatings/oxidation

- Signal verification – Use diagnostic outputs

- Flow conditioning – When straight runs are limited

Advanced Techniques

- Adaptive signal processing

- Multiple reflection paths

- Temperature-compensated calculations

- Machine learning error correction

- Self-calibration routines

Conclusion

Ultrasonic flow meters overcome small diameter challenges through advanced engineering, achieving remarkable ±0.5-1% accuracy in pipes as small as DN8 when properly applied. While transit-time technology excels in clean fluids and Doppler handles particulates, proper selection and installation prove critical for optimal performance. For ultra-precise small-pipe applications below DN15, high-end ultrasonic meters often provide the ideal balance of accuracy, reliability, and maintenance-free operation compared to alternative technologies. Always verify manufacturer specifications for your exact pipe size and fluid properties.