Need to measure flow in extreme temperature conditions? Ultrasonic flow meters handle surprisingly wide temperature ranges, but performance varies significantly by design and model. Understanding these boundaries prevents sensor failure and measurement errors.

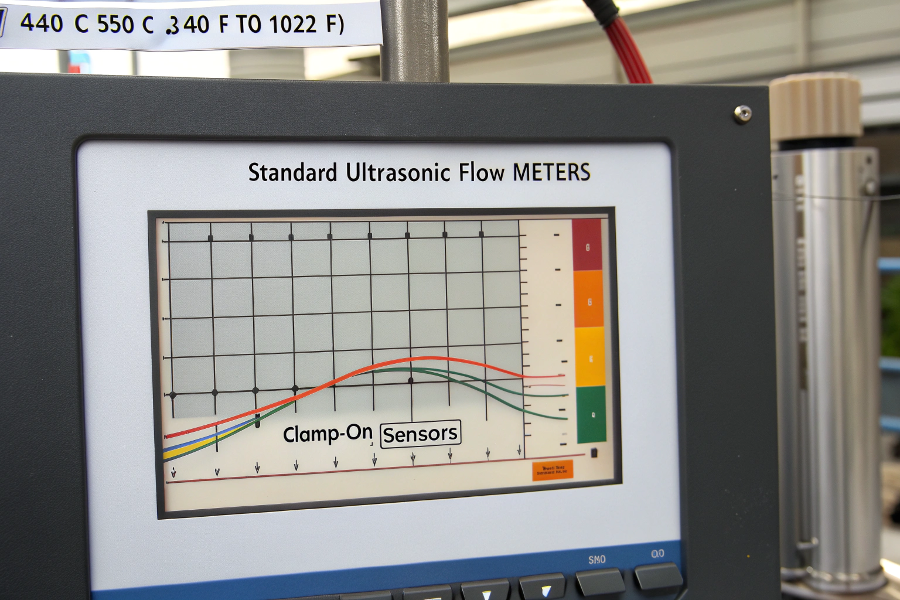

Standard ultrasonic flow meters operate from -40°C to +200°C (-40°F to 392°F), with specialized high-temperature models reaching 550°C (1022°F). Clamp-on sensors typically handle -30°C to 130°C (-22°F to 266°F), while inline wetted sensors withstand higher temperatures. Actual operating ranges depend on transducer materials, pipe conditions, and electronics design.

Operating Temperature Ranges

Temperature impacts every component of ultrasonic measurement systems. Let’s examine how different models and configurations perform across temperature extremes.

What Is the Temperature Range of Ultrasonic Flow Meters?

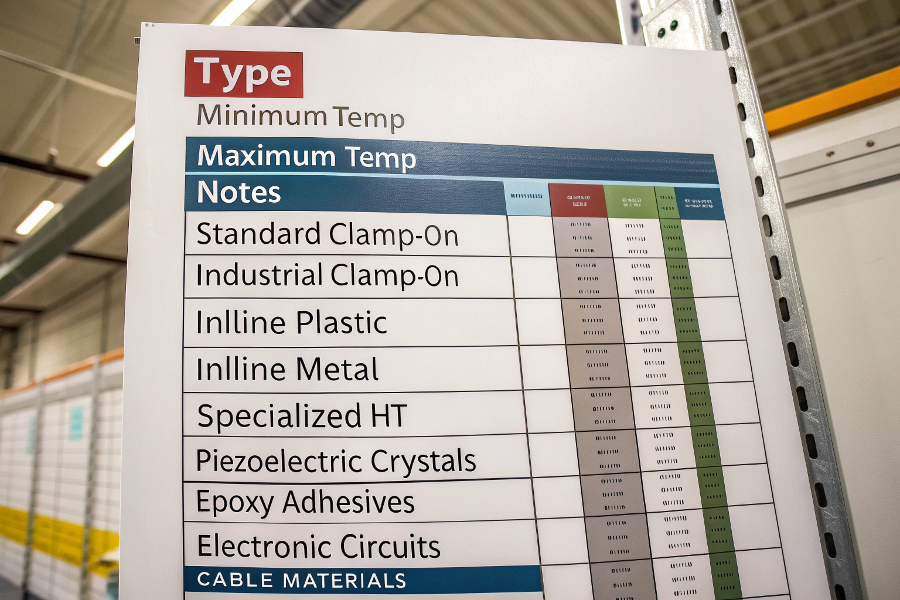

Performance varies dramatically by meter type:

| By Meter Design | Type | Minimum Temp | Maximum Temp | Notes |

|---|---|---|---|---|

| Standard clamp-on | -30°C | 130°C | Electronics limited | |

| Industrial clamp-on | -40°C | 200°C | High-temp transducers | |

| Inline plastic | -20°C | 80°C | PVDF/PTFE materials | |

| Inline metal | -40°C | 200°C | Standard wetted sensors | |

| Specialized HT | -196°C | 550°C | Cryogenic applications |

By Components

- Piezoelectric crystals: Fail above Curie temperature (~350°C)

- Epoxy adhesives: Degrade above 180°C

- Electronic circuits: Standard -20°C to 60°C

- Cable materials: PVC fails above 105°C

Component Temperature Limits

Critical Considerations

- Thermal cycling causes mounting stress

- Temperature gradients create measurement errors

- Medium changes affect sound velocity

- Pipe expansion alters acoustic path

What Is the Temperature Range for Ultrasonic Testing?

NDT testing temperatures differ from flow measurement:

| Testing Method Ranges | Technique | Temperature Range | Applications |

|---|---|---|---|

| Standard UT | -20°C to 50°C | Lab environments | |

| High-Temp UT | Up to 1200°C | Furnace inspections | |

| Cryogenic UT | Down to -269°C | LNG tank inspections | |

| Phased Array | -50°C to 175°C | Pipeline corrosion |

Special Requirements

- High-temp couplants (to 600°C)

- Water-cooled transducers

- Extended delay lines

- Thermal barrier coatings

Accuracy Impacts

- Sound velocity changes: ~1%/10°C

- Probe sensitivity variations

- Signal-to-noise ratio reduction

- Couplant thickness changes

What Is the Temperature Range of the Ultrasonic Sensor?

Sensor specifications depend on design:

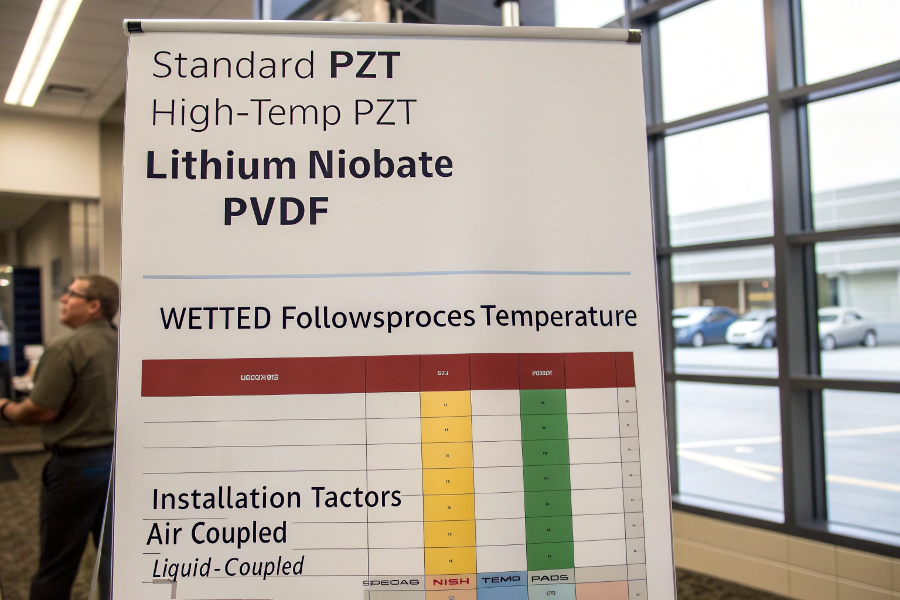

| Transducer Types | Sensor Type | Temp Range | Characteristics |

|---|---|---|---|

| Standard PZT | -30°C~85°C | Low cost, general purpose | |

| High-temp PZT | -40°C~200°C | Modified ceramics | |

| Lithium Niobate | -196°C~550°C | Extreme applications | |

| PVDF polymer | -40°C~100°C | Flexible arrays |

Installation Factors

- Air-coupled: Limited to 50°C

- Liquid-coupled: Depends on couplant

- Dry-coupled: Special high-temp pads

- Wetted: Follows process temp

Ultrasonic Sensor Types

Failure Mechanisms

- Depolarization of crystals

- Bonding adhesive failure

- Thermal expansion mismatches

- Cable insulation breakdown

What Is the Range of Ultrasonic Flow Meters?

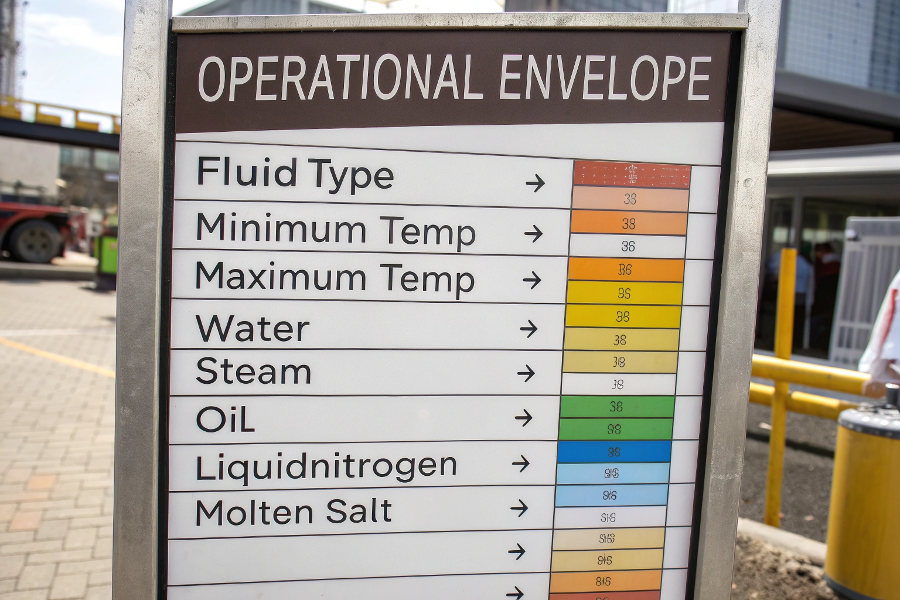

Beyond temperature, consider full operational ranges:

| Parameter | Standard Range | Extended Options |

|---|---|---|

| Pipe Size | DN15-DN5000 | DN8-DN10000+ |

| Velocity | 0.03-25 m/s | 0.01-40 m/s |

| Pressure | 0-16 bar | Vacuum to 400 bar |

| Accuracy | ±1% reading | ±0.5% with calibration |

| Fluid Conductivity | >0.05 μS/cm | Pure water possible |

| Temperature-Specific Ranges | Fluid Type | Minimum Temp | Maximum Temp |

|---|---|---|---|

| Water | 0°C | 180°C | |

| Steam | 100°C | 400°C | |

| Oil | -40°C | 200°C | |

| Liquid Nitrogen | -196°C | -150°C | |

| Molten Salt | 200°C | 550°C |

Complete Operating Ranges

Selection Guidelines for Temperature Applications

Choose using this decision matrix:

Step 1: Classify Your Application

- Cryogenic (<-50°C)

- Low temp (-50°C to 0°C)

- Ambient (0°C to 50°C)

- High temp (50°C to 200°C)

- Extreme (>200°C)

Step 2: Select Appropriate Components

- Sensors: Match to process extremes

- Cables: High-temp Teflon/Kapton

- Mounting: Thermal expansion joints

- Electronics: Remote or cooled

Step 3: Address Installation Challenges

- Thermal insulation

- Gradient management

- Cold/hot spot avoidance

- Vibration considerations

Step 4: Verify Performance

- Factory acceptance testing at temperature

- Field validation checks

- Periodic thermal recalibration

Special Solutions for Extreme Cases

- Dual-path meters for thermal gradients

- Active cooling systems

- Thermal buffer assemblies

- Transmitter relocation

Conclusion

Ultrasonic flow meters accommodate temperatures from cryogenic -196°C to extreme 550°C through specialized designs, though standard models typically operate between -40°C and 200°C. Successful high-temperature applications require careful sensor selection, proper installation techniques, and consideration of thermal effects on measurement accuracy. For ultra-high or cryogenic temperatures, consult manufacturers for custom solutions incorporating specialized materials and compensation algorithms. Always verify complete system performance at expected operating temperatures before final commissioning.