Need precise flow measurement without pipe intrusion? Ultrasonic flow meters deliver impressive accuracy – when properly selected and installed. Their performance varies dramatically based on installation and fluid conditions.

Clamp-on ultrasonic flow meters typically achieve ±1% accuracy in ideal conditions, while inline models can reach ±0.5%. Accuracy depends on pipe material, fluid type, flow profile, and proper installation following manufacturer guidelines. Transit-time designs outperform Doppler for clean fluids.

Ultrasonic Accuracy Ranges

While ultrasonic technology offers many advantages, understanding its limitations is crucial. Let’s examine what affects performance and how it compares to alternatives.

How Accurate Is an Ultrasonic Flow Meter?

Accuracy varies by design and application factors:

| Clamp-On vs. Inline Performance | Type | Best Case Accuracy | Typical Field Accuracy |

|---|---|---|---|

| Clamp-on | ±0.5-1% | ±1-2% | |

| Insertion | ±0.5% | ±1-1.5% | |

| Inline | ±0.2-0.5% | ±0.5-1% |

Fluid Dependence

- Clean water: ±0.5%

- Dirty liquids: ±1-2%

- Gases: ±1-3%

Pipe Requirements

- Smooth interior: Better accuracy

- Lined/rough pipes: Reduced performance

- Minimum straight runs: 10D upstream, 5D downstream

Pipe Requirements

Critical factors affecting precision:

- Proper transducer alignment

- Stable flow profile

- Adequate signal strength

- Correct fluid properties input

- Absence of bubbles/particulates

What Are the Limitations of an Ultrasonic Flow Meter?

Understanding constraints prevents misapplication:

Fluid Composition Issues

- Requires minimum 2% solids for Doppler

- Gas bubbles degrade transit-time performance

- Viscosity changes affect calibration

Installation Challenges

-

Pipe material affects clamp-on accuracy: Material Signal Transmission Steel Good Plastic Excellent Lined Poor Concrete Unreliable

Environmental Factors

- Temperature extremes affect transducer performance

- Vibration can cause signal interference

- Outdoor installations need weather protection

Measurement Constraints

- Minimum velocity requirements (typically 0.3 m/s)

- Limited suitability for pulsating flows

- Reduced accuracy at pipe extremes (top/bottom)

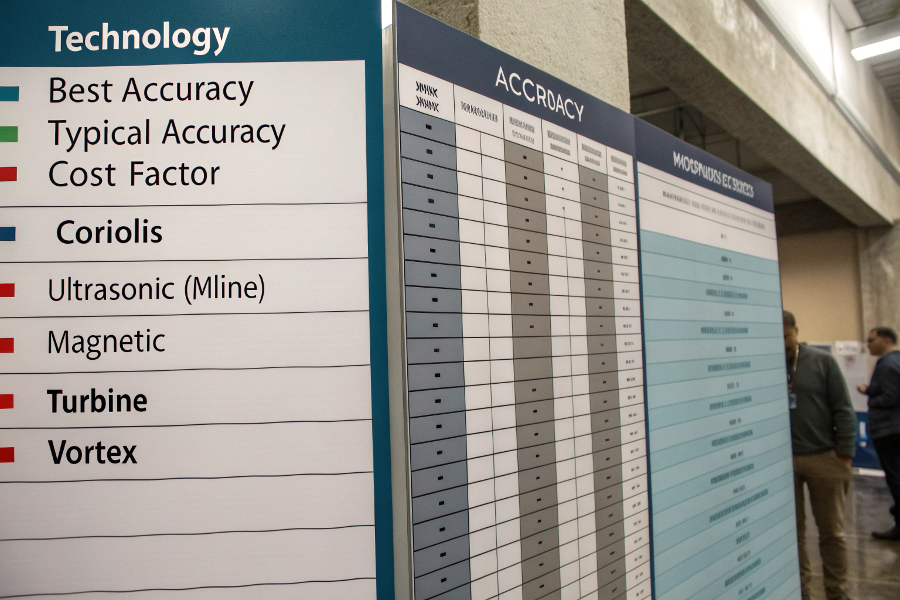

Which Flowmeter Is Most Accurate?

Comparative accuracy table:

| Technology | Best Accuracy | Typical Accuracy | Cost Factor |

|---|---|---|---|

| Coriolis | ±0.1% | ±0.2-0.5% | 5x |

| Ultrasonic (inline) | ±0.2% | ±0.5-1% | 2x |

| Magnetic | ±0.2% | ±0.5% | 3x |

| Turbine | ±0.25% | ±0.5-1% | 1.5x |

| Vortex | ±0.75% | ±1-1.5% | 1x |

Technology Accuracy Comparison

| Accuracy vs. Application Matrix: | Application | First Choice | Second Choice |

|---|---|---|---|

| Clean liquids | Coriolis | Ultrasonic | |

| Slurries | Magnetic | Doppler US | |

| Gases | Thermal | Ultrasonic | |

| Steam | Vortex | Differential | |

| High viscosity | Coriolis | Positive Disp. |

What Is the Uncertainty of the Ultrasonic Flow Meter?

Standard uncertainty components:

Measurement Variables

- Transit time measurement: ±0.1-0.5%

- Path length calculation: ±0.05%

- Angle determination: ±0.1%

- Signal processing: ±0.2%

Installation Factors

- Pipe dimension errors: ±0.5-2%

- Flow profile effects: ±0.5-3%

- Transducer misalignment: ±1-5%

Fluid Variables

- Temperature changes: ±0.2%/°C

- Composition changes: Variable

- Particulate content: ±0.5-3%

Uncertainty Contributors

| Typical Combined Uncertainty: | Condition | Uncertainty Range |

|---|---|---|

| Laboratory | ±0.25-0.5% | |

| Ideal field | ±0.5-1% | |

| Challenging field | ±1-3% | |

| Poor installation | ±5%+ |

How to Select the Right Ultrasonic Flow Meter?

Key selection criteria:

1. Application Parameters

- Fluid type (liquid/gas/steam)

- Pipe size and material

- Flow range and velocity

- Temperature/pressure range

2. Accuracy Requirements

- Process control vs. billing

- Required turndown ratio

- Calibration frequency

3. Installation Options

- Clamp-on accessibility

- Available straight runs

- Hazardous area requirements

4. Advanced Features

- Diagnostics capabilities

- Communication protocols

- Data logging needs

For best results:

- Always verify minimum/maximum velocities

- Consider redundant measurements for critical applications

- Factor in total cost of ownership

- Consult manufacturers for special cases

Selection Process Diagram

Conclusion

Ultrasonic flow meters offer excellent accuracy (typically ±0.5-1%) for clean liquids when properly installed, surpassing most mechanical meters while maintaining non-intrusive benefits. Their performance markedly decreases with dirty fluids, gas applications, or suboptimal installations. For highest accuracy applications, Coriolis remains superior, but ultrasonic provides the best balance of accuracy, versatility and cost for many industrial processes. Proper selection requires careful consideration of fluid properties, pipe conditions, and measurement requirements.