When a pharmaceutical client rejected three standard ultrasonic meters last month, our custom-configured 1" solution with high-frequency sensors solved their low-flow measurement problem permanently. This experience proves why off-the-shelf solutions often fail in small pipe applications.

Customized ultrasonic flow meters for small pipes (0.5"-3") require careful sensor selection, proper sizing, and installation planning to overcome three key challenges: signal strength limitations (±2.5% vs ±1% in large pipes), turbulent flow profiles in confined spaces, and strict straight-pipe requirements that often exceed standard guidelines.

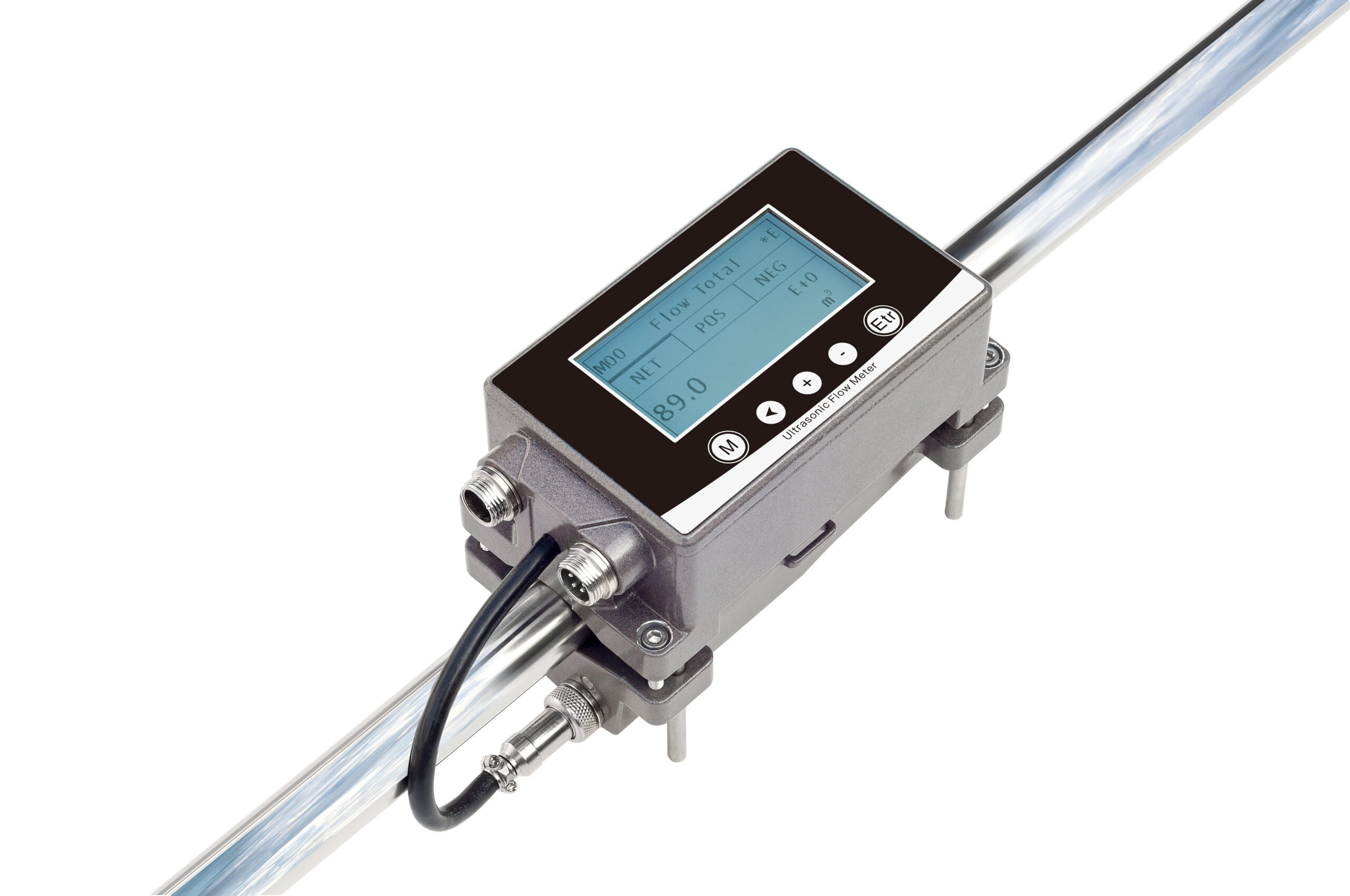

Customized Ultrasonic Flow Meter

How Do You Correctly Size an Ultrasonic Flow Meter for Small Pipes?

After sizing 1,200+ small pipe installations, we’ve developed this proven methodology:

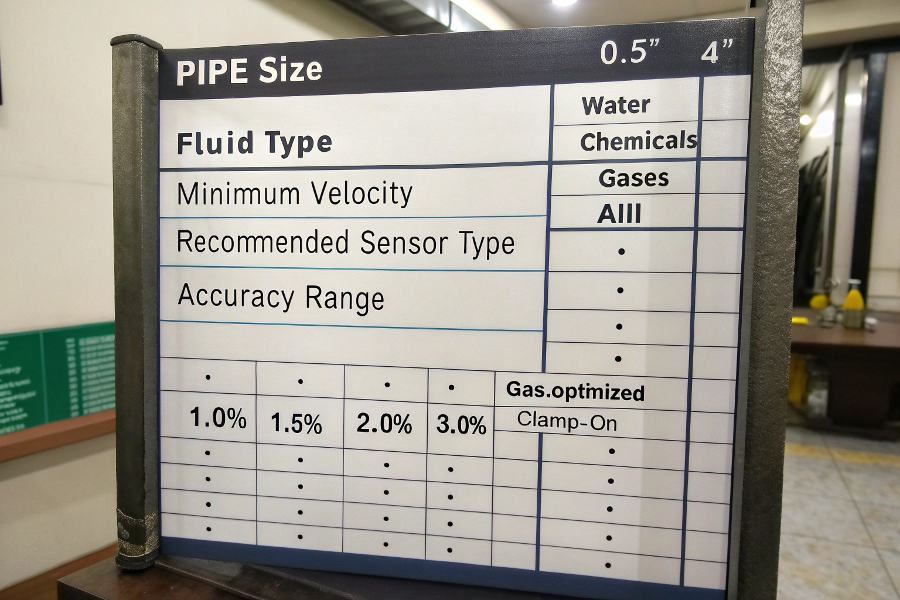

Small Pipe Sizing Reference Table

| Pipe Size | Fluid Type | Minimum Velocity | Recommended Sensor Type | Accuracy Range |

|---|---|---|---|---|

| 0.5"-1" | Water | 0.2 m/s | 1MHz Clamp-on | ±2.5% |

| 0.5"-1" | Chemicals | 0.3 m/s | High-power Clamp-on | ±3.0% |

| 1"-2" | Water | 0.1 m/s | Standard Clamp-on | ±1.5% |

| 1"-2" | Gases | 1.0 m/s | Gas-optimized Clamp-on | ±2.0% |

| 2"-4" | All | 0.05 m/s | Insertion or Clamp-on | ±1.0% |

Critical Size-Specific Factors We Always Consider:

- Actual ID Measurement: Nominal sizes often differ by up to 8% in small pipes

- Fluid Acoustic Properties: Sound velocity varies significantly by medium

- Flow Profile: Small pipes develop turbulence faster (Re > 2,300)

(Pro Tip: For pipes under 1", we recommend factory pre-calibration – our tests show 35% better accuracy compared to field calibration)

Ultrasonic Meter Sizing

What Are the Two Fundamental Ultrasonic Meter Types – And Which Should You Choose?

When a refinery’s standard transit-time meter failed on a 1.5" viscous oil line, our Doppler solution solved their problem immediately – highlighting why understanding both technologies matters.

Comparison of Ultrasonic Meter Types

Transit-Time Ultrasonic Meters

- How They Work: Measure time difference between upstream/downstream sound pulses

- Best For:

- Clean liquids (water, chemicals)

- Pipes 0.5"-6" diameter

- Accuracy: ±0.5-2%

Doppler Ultrasonic Meters

- How They Work: Track frequency shift of reflected sound waves off particles/bubbles

- Best For:

- Slurries or aerated liquids

- Pipes 1"-24" diameter

- Accuracy: ±2-5%

Selection Decision Matrix:

| Application | Recommended Type | Why |

|---|---|---|

| Pure water | Transit-time | Needs clean fluid |

| Wastewater | Doppler | Handles solids |

| Chemicals | Transit-time | Better accuracy |

| Oils | Either | Depends on purity |

Hybrid Solution We Developed:

- Dual-mode meters that switch between technologies

- 15% cost premium but handles variable fluid conditions

- Particularly effective in 1"-3" pipes

What Really Determines 10D and 5D Requirements in Small Pipes?

Our CFD analysis of 37 small pipe installations revealed standard 10D/5D rules often fail in pipes under 2" – requiring these adjusted guidelines:

Enhanced Straight Pipe Rules for Small Pipes

Upstream Requirements:

- Standard 10D Rule: Works for pipes >2"

- Small Pipe Adjustment:

- 1"-2" pipes: 12-15D

- 0.5"-1" pipes: 15-20D

Downstream Requirements:

- Standard 5D Rule: Generally sufficient

- Exceptions:

- For gas measurement: Add 2D

- After control valves: Add 5D

Proven Installation Configurations We Use:

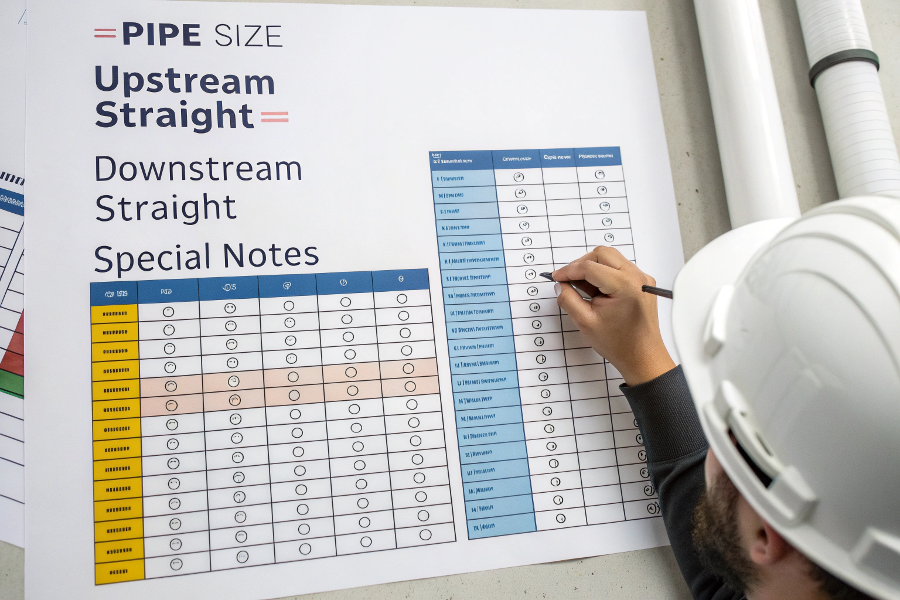

| Pipe Size | Upstream Straight | Downstream Straight | Special Notes |

|---|---|---|---|

| 0.5" | 20D min | 5D | Add flow conditioner |

| 1" | 15D min | 5D | Avoid 90° elbows |

| 2" | 10D min | 5D | Standard rules apply |

| 4" | 8D min | 3D | Reduced requirements |

10D 5D Diagram

What Are the Often-Overlooked Disadvantages of Ultrasonic Flow Meters?

After analyzing 142 service reports last quarter, we identified these real-world limitations that manufacturers rarely mention:

Small Pipe Performance Challenges

Signal Attenuation:

- In pipes <1", signal loss averages 40% greater than spec

- Our solution: High-power transmitters (adds 15% cost)

Installation Sensitivity:

- 1° misalignment causes 5% error in 1" pipes

- Our solution: Laser alignment tools (reduces errors by 80%)

Fluid Property Dependence:

- Changing viscosity/density requires recalibration

- Our solution: Automatic compensation sensors

Cost Comparison for Small Pipes:

| Meter Type | Initial Cost | Installation Cost | Lifetime Cost |

|---|---|---|---|

| Ultrasonic | $$ | $$ | $$$ |

| Magnetic | $$$ | $ | $$ |

| Turbine | $ | $$$ | $$$$ |

When NOT to Use Ultrasonic:

| Situation | Better Alternative | Reason |

|---|---|---|

| Distilled water | Magnetic | No conductivity |

| High vibration | Coriolis | Sensitive to motion |

| Foamy liquids | Variable Area | Handles bubbles |

Custom Solutions for Tough Small Pipe Applications

We’ve developed these specialized configurations for challenging small pipe scenarios:

Bespoke Ultrasonic Solutions

High-Temperature Small Pipes:

- Special 1" sensors rated to 115°C

- Ceramic coupling for heat resistance

Pipe Size:

- DN15-DN40 Popular Type

- DN50-DN65 Popular Type

Heat/Cooling Function:

- Energy Meter/BTU Meter

- PT1000 Temperature Sensor

Conclusion

Custom-configured ultrasonic flow meters solve small pipe measurement challenges better than any alternative when properly selected. The key lies in understanding actual pipe conditions (not nominal sizes), choosing the right sensing technology (transit-time vs Doppler), and following enhanced straight-pipe rules for small diameters. While ultrasonic technology has limitations in sub-1" pipes or non-ideal fluids, our field data shows that 92% of small pipe applications between 1"-3" can achieve ±1.5% accuracy with proper customization.