Is your flow meter giving inconsistent readings? You’re not alone – over 70% of industrial plants report annual flow measurement issues costing thousands in downtime and lost product.

The top 6 flow meter problems are: clogging (35% of cases), calibration drift (25%), improper installation (15%), sensor fouling (12%), mechanical wear (8%), and fluid property changes (5%). Applying proper selection, installation and maintenance protocols can prevent over 80% of failures.

Flow Meter Issues Infographic

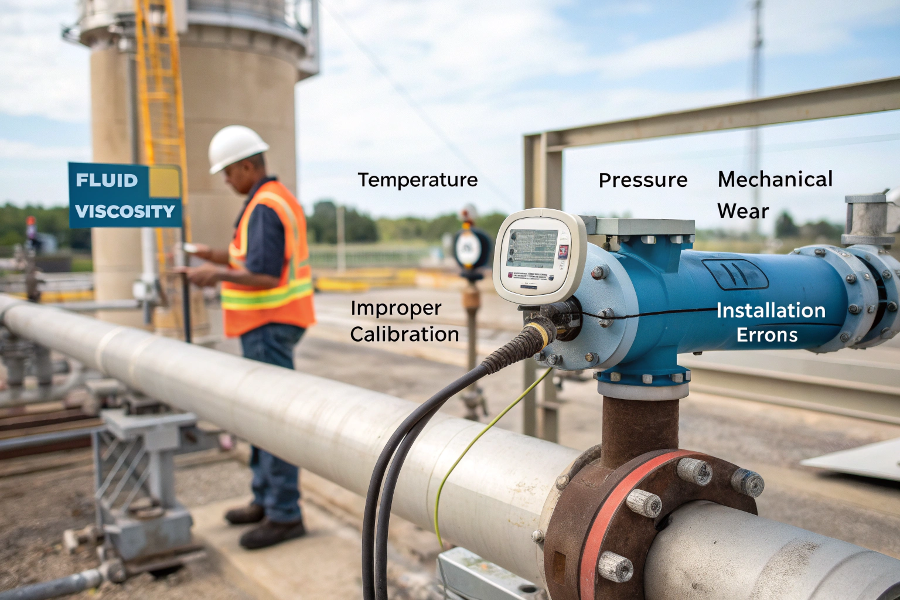

What are the four main factors affecting flow meter operation?

Flow meters often fail due to simple, preventable causes. The four primary culprits are:

1. Process conditions (fluid viscosity, temperature, pressure)

2. Mechanical wear

3. Improper calibration

4. Installation errors

Each factor impacts measurement accuracy differently, requiring specific solutions.

Flow Meter Factors

Understanding Process Condition Impacts

Every fluid behaves differently. Consider these key parameters:

| Fluid Property | Impact | Solution |

|---|---|---|

| Viscosity | Affects turndown ratio | Select Coriolis for varying viscosity |

| Temperature | Changes fluid density | Use temperature compensation |

| Pressure | Impacts gas measurements | Install pressure transmitters |

| Conductivity | Critical for magmeters | Ensure minimum 5μS/cm |

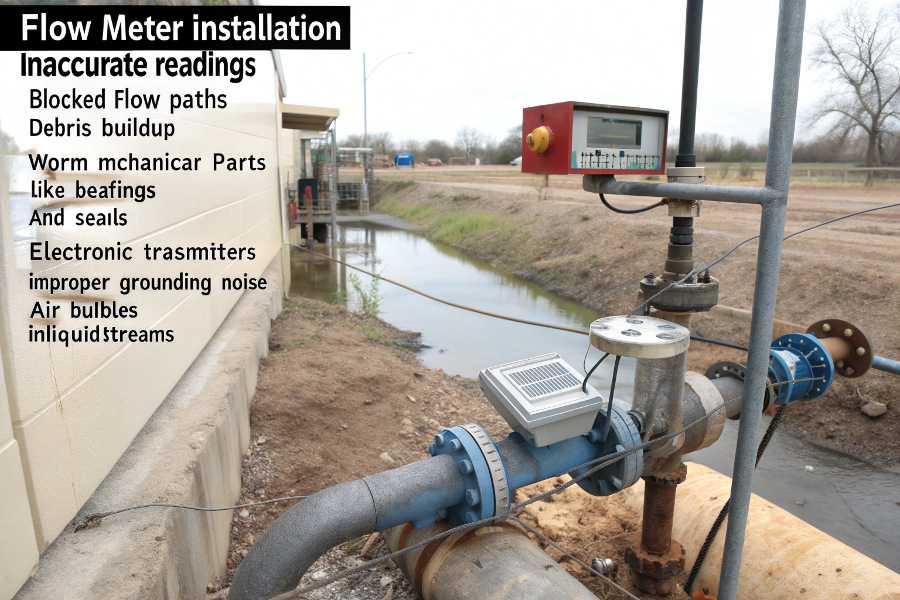

What causes inaccurate flow measurements?

Inaccurate readings typically stem from one of these sources:

- Blocked flow paths from debris buildup

- Worn mechanical parts (bearings, seals)

- Electronic drift in transmitters

- Improper grounding causing noise

- Air bubbles in liquid streams

Accuracy Factors

Case Study: Chemical Plant

A specialty chemical plant saw ±12% flow variations. Diagnosing revealed:

- Improper grounding (50% of error)

- Temperature fluctuations (30%)

- Minor clogging (20%)

Solution: Added isolated ground, temperature compensation, and monthly cleaning. Accuracy improved to ±0.5%.

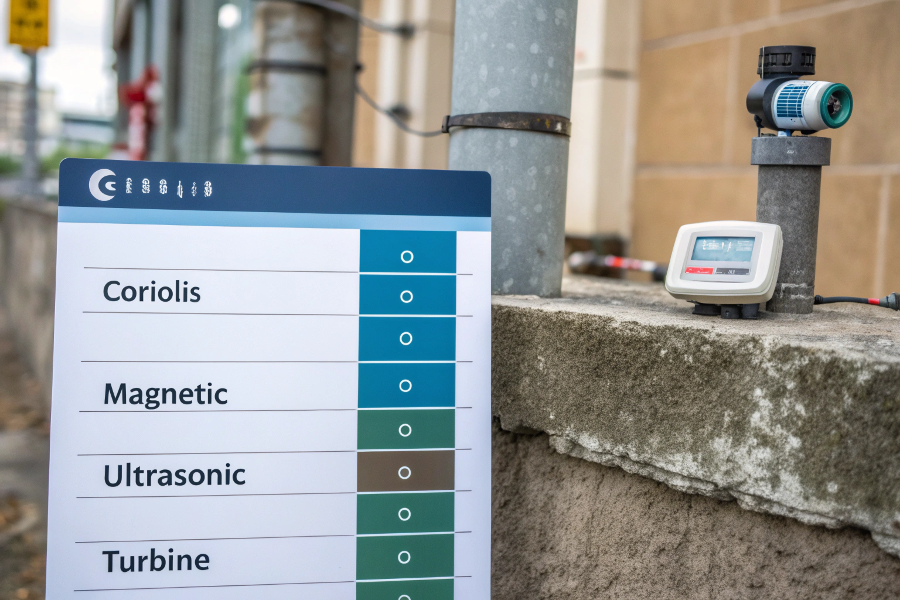

Which flow meter type works best for industrial applications?

The optimal meter depends on your application:

| Meter Type | Best For | Accuracy | Maintenance |

|---|---|---|---|

| Coriolis | High viscosity, slurries | ±0.1% | Low |

| Magnetic | Conductive liquids | ±0.5% | Medium |

| Ultrasonic | Clean liquids/gases | ±1% | Very Low |

| Turbine | Low-viscosity fluids | ±0.25% | High |

Meter Types Comparison

Selecting the Right Technology

Consider these key factors:

- Fluid type (liquid/gas, purity)

- Flow range (minimum/maximum rates)

- Pipe size and material

- Process conditions (temp, pressure)

- Accuracy requirements

How can you minimize flow meter errors?

Proactive maintenance reduces errors by over 90%:

Monthly:

- Visual inspection for leaks/damage

- Check grounding connections

- Verify zero readings

Quarterly:

- Full sensor cleaning

- Calibration checks

- Performance validation

Annually:

- Complete recalibration

- Component replacement

- Full diagnostic test

Maintenance Guide

Maintenance Cost-Benefit

Investment in proper maintenance yields impressive ROI:

| Activity | Cost | Savings | Payback Period |

|---|---|---|---|

| Calibration | $500 | $15,000 | <1 month |

| Cleaning | $200 | $8,000 | 1 week |

| Training | $1,000 | $50,000 | 3 months |

Conclusion

Flow meter failures stem mainly from preventable issues – most can be avoided through proper selection, installation and maintenance. Implement these best practices to maximize uptime and accuracy.