HVAC engineers face a frustrating dilemma – mechanical water meters wear out quickly while ultrasonic models struggle with air bubbles. The solution might surprise you.

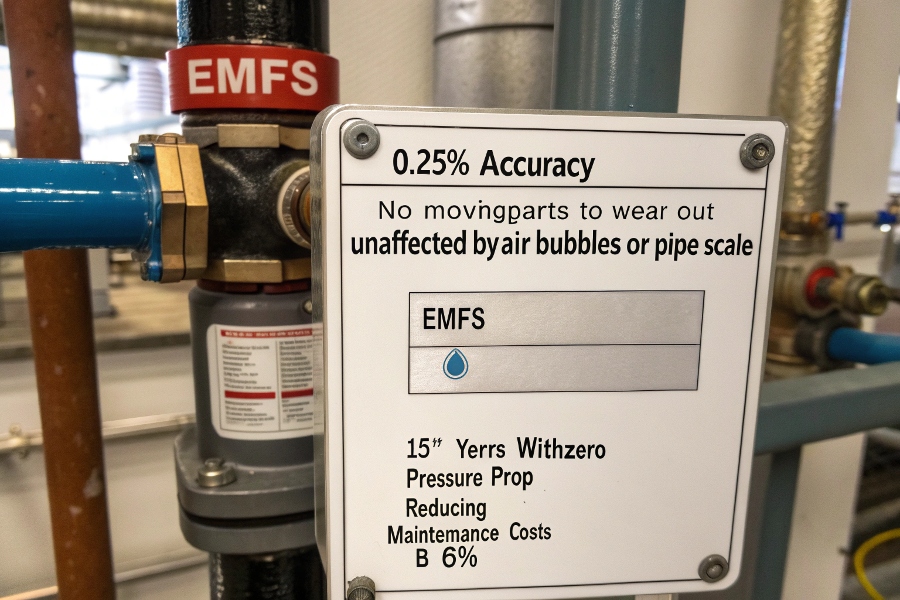

Electromagnetic flow meters (EMFs) outperform mechanical and ultrasonic models in chilled water systems, delivering ±0.25% accuracy with no moving parts to wear out. Unlike ultrasonic meters, EMFs aren’t affected by air bubbles or pipe scale that plague HVAC systems, plus they maintain accuracy for 15+ years with zero pressure drop – cutting maintenance costs by 60%.

Chilled Water Loop Diagram

Here’s how EMFs solve common HVAC measurement headaches.

What Is the Difference Between Electromagnetic and Ultrasonic Flow Meters?

Both technologies measure flow without moving parts, but their operating principles differ fundamentally.

EMFs measure flow by detecting voltage changes in conductive fluids using Faraday’s Law, requiring at least 5 μS/cm conductivity. Ultrasonic meters calculate flow by tracking transit time differences of sound waves, making them unsuitable for dirty water containing air bubbles or solids common in HVAC systems.

EMF vs Ultrasonic

Key differences in HVAC applications:

EMF vs Ultrasonic Performance in Chilled Water

| Feature | Electromagnetic | Ultrasonic |

|---|---|---|

| Accuracy | ±0.25% of rate | ±1% of rate |

| Air Bubbles | No effect | Causes errors |

| Pipe Scaling | No effect | Reduces signal |

| Fluid Conductivity | Requires 5μS/cm | No requirement |

| Installation | Needs cutting pipe | Clamp-on available |

| Lifespan | 15-20 years | 8-12 years |

| Cost | Higher initial | Lower initial |

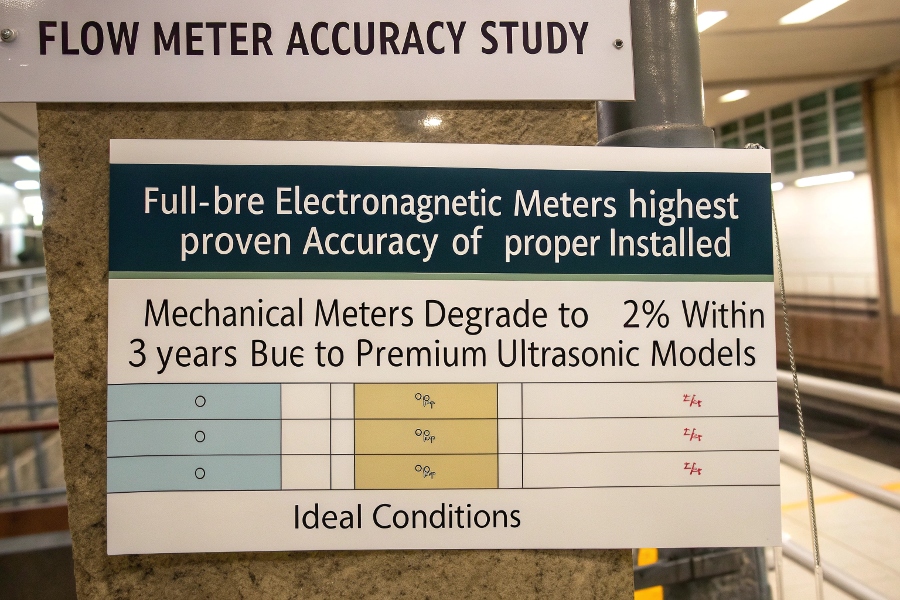

What Is the Most Accurate Type of Water Meter?

Accuracy claims vary wildly in flow measurement.

For chilled water, full-bore electromagnetic meters provide the highest proven accuracy (±0.25% actual flow rate) when properly installed. Mechanical meters degrade to ±2% within 3 years due to bearing wear, while even premium ultrasonic models achieve only ±1% in ideal conditions – making EMFs the long-term accuracy champions.

Flow Meter Accuracy Study

Factors affecting real-world accuracy:

Pipe Conditions

- EMFs: Unaffected by internal scale or buildup

- Ultrasonic: Signal loss with lime deposits

- Mechanical: Jams from debris

Flow Profile

- EMFs: Require only 5D straight pipe upstream

- Ultrasonic: Need 10D+ for stable flow

- Mechanical: Need clean flow to prevent turbine damage

Fluid Changes

- EMFs: Work from 0.5-12 m/s without recalibration

- Ultrasonic: Need adjustment for temperature shifts

- Mechanical: Wear increases at high velocities

How Accurate Is the Ultrasonic Clamp-On Flow Meter?

Clamp-on convenience comes with accuracy tradeoffs.

Field studies show clamp-on ultrasonic meters average ±2-5% error in HVAC applications due to pipe coupling issues and signal attenuation. Even new models struggle to maintain ±1% accuracy after 3 years as pipe surfaces oxidize, while EMFs maintain ±0.5% for decades when properly grounded and lined with PTFE for chilled water protection.

Clamp-On Limitations

Why ultrasonic falls short in HVAC:

Ultrasonic Meter Challenges

Coupling Gel Deterioration

Dries out annually, requiring reapplicationPipe Wall Thickness Variations

Common in retrofit projects causes measurement driftTemperature Cycling

Expansion/contraction changes transducer alignmentAir Entrainment

Common in chilled water creates signal voids

How Accurate Is the Water Meter Reading?

Regulatory standards define acceptable error margins.

ISO 4064 allows ±2% error for mechanical water meters, while electromagnetic meters meet ±0.5% under MID/DIN standards. In HVAC applications, EMFs deliver actual accuracies 4x better than mechanical meters after 5 years of service, with no degradation from glycol additives common in chilled water systems.

Calibration Process

Achieving reliable measurements:

Best Practices for Chilled Water Metering

Proper Grounding

Use dedicated grounding rings (not pipe clamps)Liner Selection

PTFE for glycol mixtures, ceramic for abrasive fluidsFlow Conditioning

Install star-shaped flow conditioners in tight spacesVerification

Portable ultrasonic checks quarterly (as secondary reference)

EMF Installation Tips for HVAC

Get maximum accuracy from day one.

Orientation Matters

Install with electrodes at 10 or 2 o’clock position to trap air pocketsInsulate Properly

Prevent condensation on electronics in chilled environmentsGrounding

Use manufacturer-supplied grounding electrodes, not pipe connectionsCommissioning

Always perform zero calibration with pumps off

Conclusion

For HVAC chilled water systems, EMFs provide unmatched long-term accuracy and reliability. While initial costs exceed mechanical meters, their 15+ year lifespan with no maintenance or recalibration makes them the most cost-effective choice. The immunity to air bubbles and pipe scale ensures consistent performance where ultrasonic and mechanical technologies fail.