Struggling to select the perfect flow meter? The wrong choice can cost thousands in rework and lost efficiency.

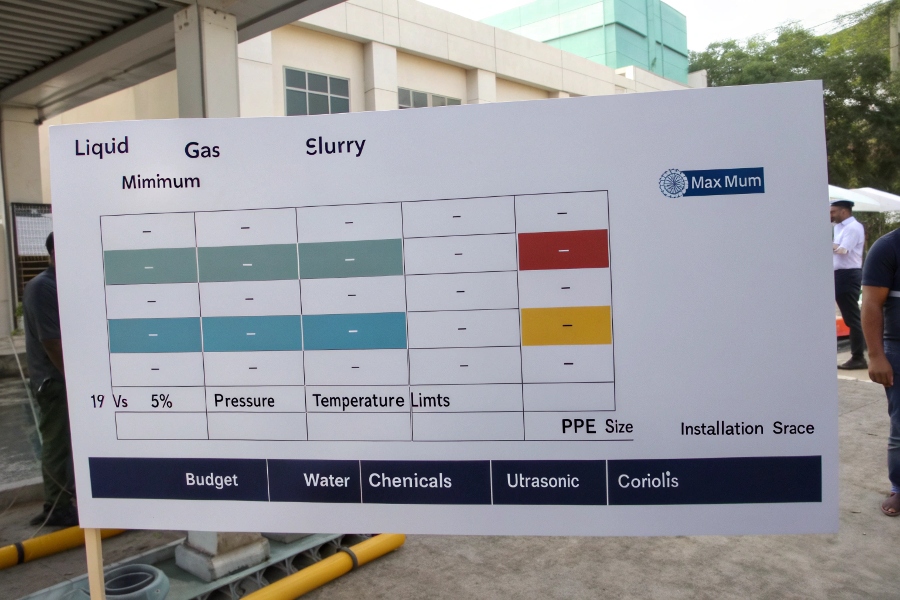

Choose a flow meter by evaluating: fluid type (liquid/gas/slurry), flow range (min/max values), accuracy needs (±1% vs ±5%), pressure/temperature limits, pipe size, installation space, and budget. Magnetic suits water/chemicals, ultrasonic for clean liquids, Coriolis for mass flow measurements.

Flow Meter Type Comparison

Here’s your comprehensive guide to avoid costly selection mistakes.

How Do You Choose a Flow Meter?

Selection starts with understanding your fluid’s behavior.

For water-like fluids: Magnetic flow meters (conductive liquids), ultrasonic (clean liquids), or turbine (stable flows). For viscous/oily fluids: Coriolis (mass flow) or positive displacement. Gases demand thermal or differential pressure meters. Slurries need abrasion-resistant mag meters.

Flow Meter Compatibility by Fluid Type

Critical selection criteria:

Flow Meter Selection Matrix

| Fluid Characteristic | Best Meter Types | Worst Choices |

|---|---|---|

| Conductive liquid | Magnetic, Ultrasonic | Turbine, Vortex |

| Non-conductive | Ultrasonic, Coriolis | Magnetic |

| High viscosity | Coriolis, PD | Turbine, Orifice |

| Two-phase flow | Coriolis (limited), Special US | Magnetic, Vortex |

| Low pressure | Ultrasonic, Turbine | Orifice, Venturi |

What Are the Considerations of Flow Meter?

Overlooking installation realities causes 40% of failures.

Prioritize: fluid compatibility1 (pH, abrasives), turndown ratio2 (10:1 typical), output needs (4-20mA/Pulse/Bus), maintenance access3, and certification requirements (EX/ATEX for hazardous areas). Temperature extremes may rule out ultrasonic meters.

Typical Installation Layout

Essential evaluation factors:

Total Ownership Cost Breakdown

| Cost Factor | Magnetic Example | Coriolis Example |

|---|---|---|

| Purchase Price | $2,500 | $8,000 |

| Installation | $500 (wafer-style) | $1,200 (supports) |

| Calibration (5yrs) | $300 | $1,500 |

| Energy Consumption | 15W ($30/yr) | 30W ($60/yr) |

| Expected Life | 12-15 years | 8-10 years |

What Is the Rule of Thumb for Flow Meter Installation?

Poor installation degrades accuracy by 50%.

Follow these rules: 1) 10x pipe diameter straight run upstream (5x downstream), 2) Avoid pump/valve turbulence (install after elbows), 3) Keep mag meters always full (vertical upward flow preferred), 4) Ground properly (1-ohm resistance max), 5) Shield electronics from extreme heat (>60°C).

Proper Straight Run Requirements

Installation critical checks:

Minimum Straight Pipe Requirements

| Meter Type | Upstream (Diameters) | Downstream (Diameters) |

|---|---|---|

| Magnetic (standard) | 5D | 3D |

| Ultrasonic | 10D | 5D |

| Coriolis | 0D | 0D |

| Turbine | 15D | 5D |

| Orifice Plate | 20D | 10D |

What Are the Standard Conditions for a Flow Meter?

Spec sheets assume ideal scenarios that rarely exist.

Standard calibration conditions4: 20°C ambient, 1013 mbar pressure, water as fluid (1cP viscosity), fully developed flow profile. Real-world compensation needed for temperature (-0.1%/°C typical), pressure (+0.01%/bar), and viscosity effects (critical below 5cP).

Calibration Standards Hierarchy

Performance adjustment factors:

Environmental Impact Corrections

| Parameter | Effect on Accuracy | Compensation Method |

|---|---|---|

| Temperature change | ±0.15%/10°C | Built-in PT100/software |

| Pressure variation | ±0.05%/bar | Software offset (if available) |

| Viscosity shift | ±1%/cP change | Recalibration recommended |

| Solids content | -0.5% per 1% solids | Special liners/electrodes |

Future-Proofing Your Flow Meter Selection

Tomorrow’s plants demand smarter instrumentation today.

Three key upgrades: 1) IIoT readiness (WirelessHART/MQTT)5, 2) Advanced diagnostics (electrode wear monitoring), 3) Multiparameter outputs (flow + density/temperature). Magnetic meters now offer predictive liner failure alerts via impedance tracking.

Industry 4.0 Connectivity

Evolutionary features comparison:

Traditional vs Smart Flow Meters

| Capability | Conventional | Smart Meter Advantage |

|---|---|---|

| Fault Detection | Alert after failure | Predicts issues (e.g., coating) |

| Data Access | Local display only | Cloud dashboard + API |

| Calibration | Annual manual checks | Continuous self-validation |

| Power Supply | Wired 24V DC | Battery + energy harvesting |

Conclusion

Selecting the right flow meter requires balancing fluid properties, accuracy needs, installation constraints, and future connectivity – with magnetic flow meters offering the broadest liquid application coverage.

Understanding fluid compatibility is crucial for ensuring the longevity and accuracy of flow meters in various applications. ↩

The turndown ratio affects the flow meter’s performance range, making it essential for accurate measurements across varying flow rates. ↩

Easy maintenance access can significantly reduce downtime and costs, ensuring efficient operation of flow measurement systems. ↩

Understanding standard calibration conditions is crucial for accurate flow meter performance in real-world applications. ↩

Explore how IIoT readiness enhances flow meter capabilities, ensuring your instrumentation is future-proof and efficient. ↩