Magnetic flow meters revolutionized industrial flow measurement since their introduction in the 1950s. Understanding their working principle is essential for proper selection and operation.

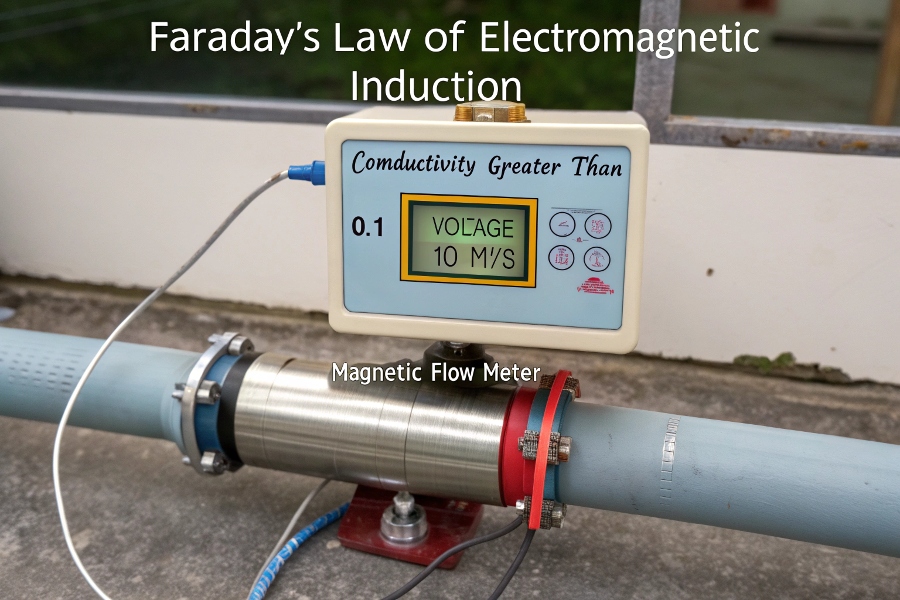

Magnetic flow meters operate on Faraday’s Law of Electromagnetic Induction – when a conductive fluid flows through a magnetic field, it generates a voltage proportional to flow velocity (typically 0.1-10 m/s range). This induced voltage (measured between electrodes) directly indicates flow rate, requiring fluid conductivity >5μS/cm for reliable operation.

Faraday’s Law of Electromagnetic Induction

Having supplied these meters globally, I’ll explain these concepts clearly.

What Is the Working Principle of Magnetic Flow Meter?

The physics behind these meters is both elegant and practical.

The core principle involves: 1) Generators creating a controlled magnetic field1 perpendicular to flow, 2) Electrodes measuring voltage induced across moving conductive liquid, 3) Electronics converting this mV signal to flow rate using the known pipe diameter, with accuracy ±0.5% of reading being typical for modern meters.

Magnetic Flow Meter Working Principle

These elements work together precisely:

Key Components and Their Functions

| Component | Function | Typical Specifications | Critical Factors |

|---|---|---|---|

| Excitation Coils2 | Generate magnetic field | 50/60Hz AC or pulsed DC | Field strength uniformity |

| Electrodes | Detect induced voltage | 316SS, Hastelloy, titanium | Material compatibility |

| Liner | Protect from fluid contact | PTFE, rubber, PFA | Temperature resistance |

| Converter | Process electrode signals | 4-20mA, pulse, digital outputs | Signal-to-noise ratio |

| Ground Ring | Ensure proper electrical path | Mateirals match electrodes | Essential for conductivity |

What Is Flow Meter Principle of Operation?

Different flow technologies use distinct physical principles.

Compared to other flow meters: 1) Turbine/K-factor meters measure mechanical rotation, 2) Ultrasonic use transit-time differences, 3) Coriolis detect mass flow via vibration, while magnetic meters uniquely require no moving parts and measure only conductive fluids (water, acids, slurries being ideal applications).

Flow Meter Technology Comparison

Here’s how they differ fundamentally:

Operating Principle Comparison Table

| Meter Type | Physical Principle | Best For | Limitations |

|---|---|---|---|

| Magnetic | Faraday’s Law (voltage induction) | Conductive liquids | Needs minimum conductivity |

| Ultrasonic | Time-of-flight difference | Clean liquids/gases | Affected by bubbles |

| Coriolis | Mass flow via tube oscillation | High accuracy needed | High cost, pressure drop |

| Turbine | Blade rotation counting | Mid-range clean liquids | Wear with particulates |

| Differential Pressure3 | Bernoulli’s principle | Gas/steam applications | Permanent pressure loss |

What Are the Requirements for a Magnetic Flow Meter Straight Run?

Proper installation ensures measurement accuracy.

Minimum straight pipe requirements are: 1) 10 pipe diameters upstream (5 downstream) for most applications, 2) Extend to 20D upstream for slurry/special flows, 3) Never install immediately after elbows/valves/pumps which distort flow profile, with exceptional cases requiring flow conditioners when space is limited.

Magnetic Flow Meter Installation

These distances prevent measurement errors:

Straight Run Requirements Guide

| Disturbance Type | Minimum Upstream | Minimum Downstream | Flow Conditioner Solution |

|---|---|---|---|

| Single 90° elbow | 10D | 5D | Reduces to 5D if needed |

| Pump discharge | 20D | 10D | Special flow straightener |

| Control valve | 15D | 7D | Must be fully open |

| T-junction | 20D | 10D | Install flow conditioner |

| Pipe expansion | 15D | 10D | conical transition helps |

Conclusion

Magnetic flow meters provide reliable, obstruction-free measurement for conductive fluids by applying electromagnetic induction principles from Faraday’s Law. Proper understanding of both their working principle and installation requirements (especially straight pipe needs) ensures optimal performance in industrial applications.

This resource will provide insights into the significance of controlled magnetic fields in flow measurement technology, crucial for accurate readings. ↩

Understanding the role of Excitation Coils can enhance your knowledge of flow meter technology and its applications. ↩

Learning about Differential Pressure flow meters will provide insights into their applications and the challenges they present in measurement accuracy. ↩