Industrial processes often involve challenging fluids. Many engineers wonder if electromagnetic flow meters can withstand corrosive and abrasive media while maintaining accuracy.

Properly configured electromagnetic flow meters can handle most corrosive and abrasive fluids when equipped with specialized liners (PTFE, PFA, rubber) and electrode materials (Hastelloy, titanium, platinum), making them suitable for chemical processing, mining, and wastewater applications.

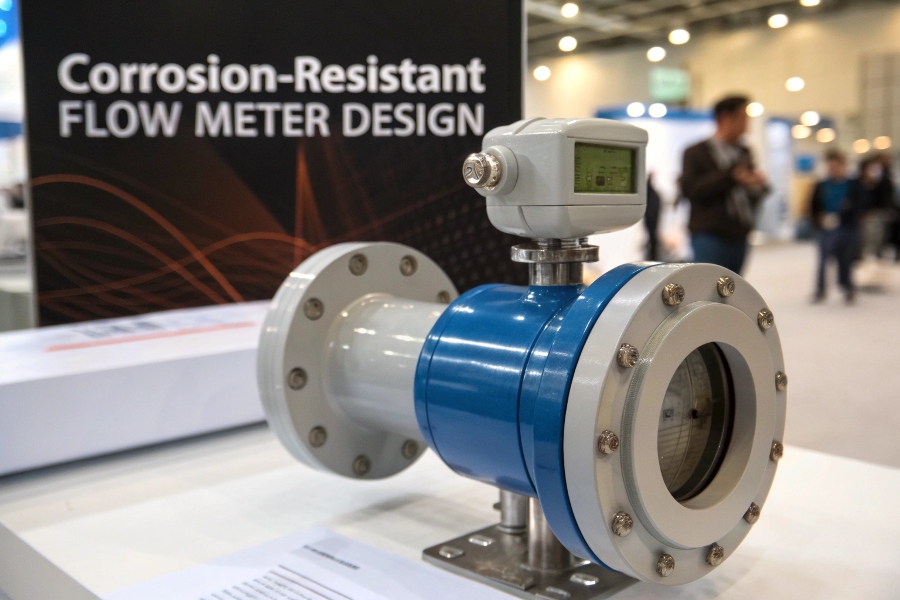

Corrosion-Resistant Flow Meter Design

Let me share insights from our extensive field experience with challenging fluid measurements.

What Are the Limitations of Electromagnetic Flow Meter?

Every technology has boundaries to consider.

Electromagnetic flow meters cannot measure non-conductive fluids (conductivity <5 μS/cm), require full pipe conditions, and face limitations with extremely high-temperature (typically <180°C) or high-pressure (>PN40) applications without special designs.

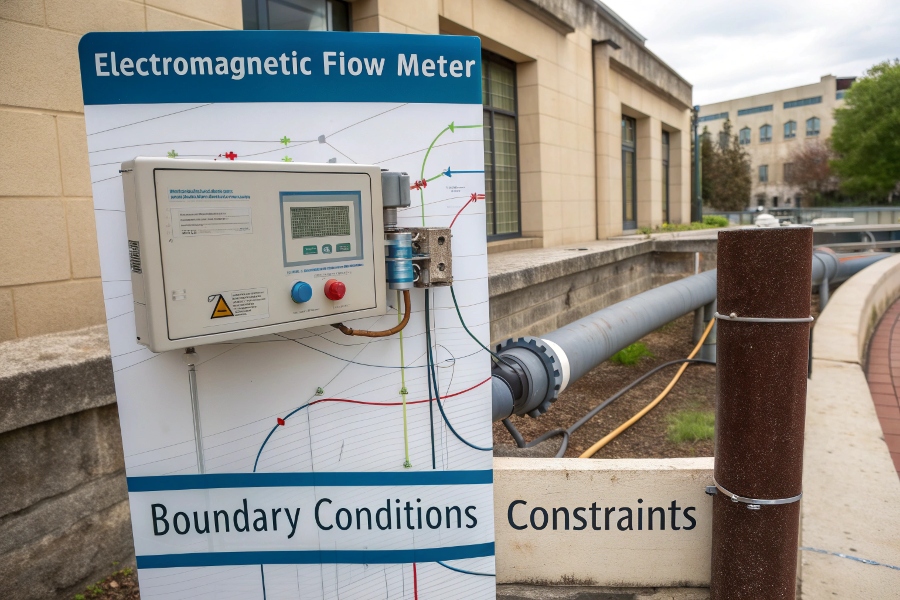

Electromagnetic Flow Meter Boundary Conditions

Understanding these constraints helps proper selection:

Common Application Boundaries

| Limitation Factor | Standard Range | Specialized Solutions |

|---|---|---|

| Fluid Conductivity | >5 μS/cm | Not applicable for oils/gases |

| Temperature Range | -20°C to +180°C | High-temp versions to 250°C |

| Pressure Rating | PN16 to PN40 | High-pressure to PN160 |

| Pipe Size | DN3 to DN3000 | Custom sizes available |

| Flow Velocity | 0.3-10 m/s | Extended range options |

These limitations often determine when alternative technologies become necessary.

What Flow Meter for Corrosive Liquids?

Material selection becomes critical.

For corrosive liquids, electromagnetic flow meters with PTFE/PFA liners and Hastelloy/titanium electrodes provide excellent resistance, while alternative technologies like ceramic-body Coriolis meters or lined ultrasonic meters may suit extreme cases.

Flow Meter for Corrosive Applications

Our material selection guidelines:

Material Compatibility Guide

| Fluid Type | Recommended Liner | Electrode Material |

|---|---|---|

| Strong acids (HCl, H2SO4) | PFA | Hastelloy C276 |

| Caustics (NaOH, KOH) | PTFE | 316L stainless |

| Salt solutions | PTFE/PFA | Titanium |

| Slurries (<25% solids) | Hard rubber | Platinum-iridium |

| Organic solvents | PFA | Tantalum |

Proper material pairing1 prevents premature failure in corrosive services.

Which Liquid Cannot Be Measured by the Magnetic Flowmeter?

Conductivity defines applicability.

Electromagnetic flow meters cannot measure hydrocarbons (oil, diesel), gases (air, steam), pure water (DI water <5 μS/cm), or non-conductive solvents – requiring alternative technologies like Coriolis or ultrasonic flow meters.

Flow Measurement Alternatives

Key measurement exclusions:

Incompatible Fluid Types

Hydrocarbons

- Crude oil

- Diesel fuel

- Liquid propane

Gases & Steam

- Compressed air

- Natural gas

- Process steam

Ultra-Pure Liquids

- DI water

- Semiconductor chemicals

- Some pharmaceuticals

Non-Polar Solvents

- Toluene

- Hexane

- Silicone oils

When conductivity drops below 5 μS/cm, alternative technologies become necessary.

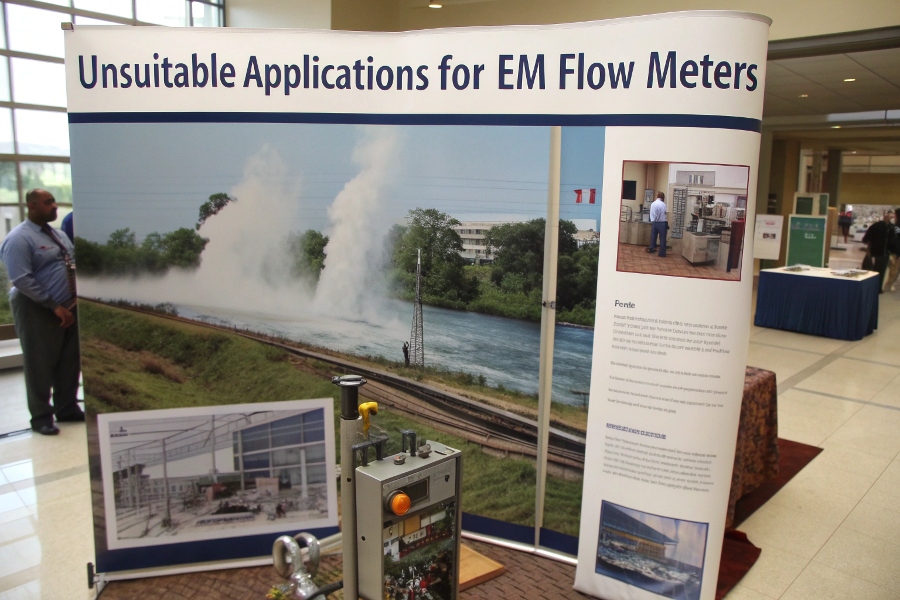

Which of the Following Are Not Suitable With Electromagnetic Flow Meter?

Application matching prevents failures.

Oil pipelines, steam systems, gas distribution, and ultrapure water systems are fundamentally incompatible with electromagnetic flow meters due to conductivity requirements2, while slurry services require special abrasion-resistant designs.

Unsuitable Applications for EM Flow Meters

Real-world exclusion examples:

Common Unsuitable Applications

| Industry | Typical Fluid | Reason for Incompatibility |

|---|---|---|

| Oil & Gas Production | Crude oil | Non-conductive |

| Power Generation | Steam | Gas phase |

| Semiconductor | Ultra-pure water | Low conductivity |

| LPG Handling | Liquid propane | Non-conductive |

| Compressed Air | Plant air | Gas phase |

Understanding these boundaries ensures proper technology selection.

Conclusion

Electromagnetic flow meters excel with corrosive/abrasive conductive liquids when properly configured, but cannot measure non-conductive fluids – requiring careful application analysis before selection.