Need to measure liquid flow precisely? While electromagnetic flow meters offer excellent accuracy, they only work with certain types of fluids. Understanding these limitations helps select the right meter for your application.

Electromagnetic flow meters measure electrically conductive liquids1 including water, acids, and slurries, but cannot measure non-conductive fluids like oils or gases. These devices are widely used in water treatment, chemical processing, and food production where ±2% accuracy is becoming standard.

Fluid Measurement with Electromagnetic Flow Meter

Electromagnetic technology provides reliable flow measurement without moving parts. But what makes some fluids measurable while others aren’t? Let’s examine the specifics.

What Different Fluids Can Be Used for Flow Measurement Using Electromagnetic Flow Meter?

When selecting a flow meter, the fluid’s conductivity is the deciding factor. Not all liquids will generate the necessary electrical signal.

Electromagnetic flow meters require fluids with minimum conductivity of 5 μS/cm, making them ideal for water, wastewater, acids, bases, and slurries containing conductive particles2.

Conductivity Requirements for Flow Measurement

The relationship between fluid properties and measurement capability becomes clearer when we examine specific examples:

Suitable Fluids and Their Characteristics

| Fluid Category | Conductivity Range | Common Examples | Measurement Challenges3 |

|---|---|---|---|

| Potable Water | 50-1500 μS/cm | Tap water, filtered water | Low conductivity in pure forms |

| Industrial Wastewater | 500-10000 μS/cm | Plant discharge, mining effluent | Abrasive particles |

| Acids & Bases | >1000 μS/cm | Sulfuric acid, caustic soda | Corrosive properties |

| Food Liquids | 100-5000 μS/cm | Milk, juices, syrups | Hygiene requirements |

Recent industry trends toward ±2% accuracy demand even more precise conductivity measurements, especially in critical processes like chemical dosing or batch operations.

What Does an Electromagnetic Flow Meter Measure?

Understanding the measurement principle explains both the capabilities and limitations of these devices.

Electromagnetic flow meters measure the velocity of conductive fluids by detecting voltage changes induced when the fluid moves through a magnetic field, then calculating volumetric flow rate.

How Electromagnetic Flow Meters Work

The physics behind the measurement reveals why fluid conductivity matters so much:

Detailed Measurement Process

- Magnetic Field Generation: Coils create a controlled magnetic field perpendicular to fluid flow

- Charge Separation: Moving conductive fluid generates voltage via Faraday’s Law of Induction

- Electrode Detection: Paired electrodes measure the induced voltage proportional to flow velocity

- Flow Calculation: Microprocessor converts voltage signal to flow rate using pipe dimensions

Key formula:

Flow Rate (Q) = (Measured Voltage × Pipe Cross-Section) / (Magnetic Flux Density)

This principle explains why manufacturers are now developing enhanced signal processing to achieve the ±2% accuracy demanded by modern industries.

Which Liquid Cannot Be Measured by the Magnetic Flowmeter?

Recognizing incompatible fluids prevents costly measurement errors and equipment mismatches.

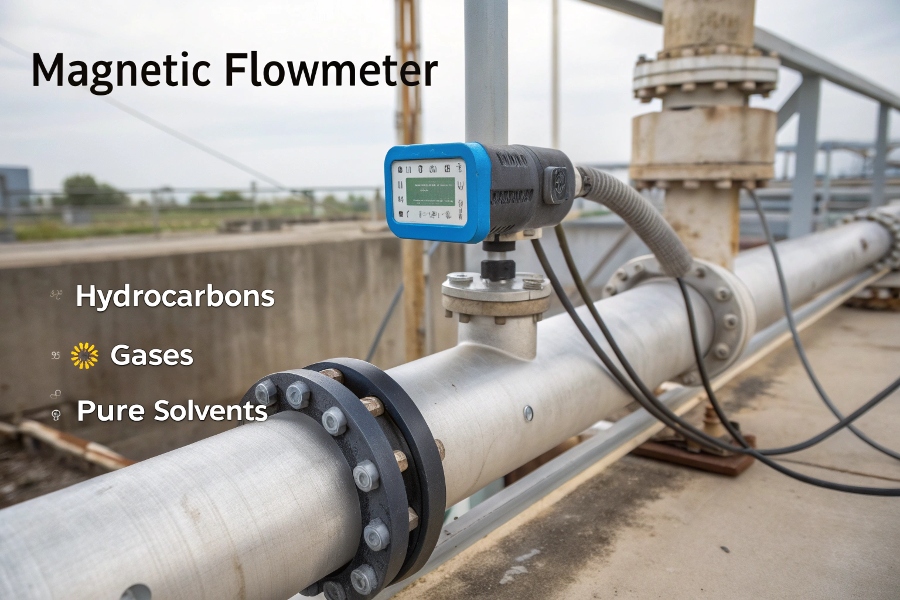

Magnetic flowmeters cannot measure non-conductive liquids4 including hydrocarbons, gases, and pure solvents, or any fluid with conductivity below 5 μS/cm such as distilled water.

Incompatible Fluids for Magnetic Flowmeters

The limitations stem from fundamental physics requirements:

Why Certain Fluids Don’t Work

Hydrocarbons & Oils

- Conductivity: <1 μS/cm

- Examples: Crude oil, diesel, kerosene

- Problem: Insufficient charge carriers for detection

Gases & Vapors

- Conductivity: None

- Examples: Natural gas, steam, compressed air

- Problem: No continuous conductive path

Ultra-Pure Liquids

- Conductivity: <5 μS/cm

- Examples: Deionized water, pharmaceutical solvents

- Problem: Missing dissolved ions to carry current

For these fluids, alternative technologies like ultrasonic or Coriolis flow meters prove more effective. The industry’s move toward higher accuracy makes proper technology selection even more critical.

What Are the Applications of Magnetic Flow Meter?

From clean water to corrosive chemicals, these meters serve diverse industries with reliable measurements.

Magnetic flow meters excel in water management, chemical processing, mining, and food production where they measure conductive, abrasive, or viscous fluids without obstruction or maintenance issues.

Industrial Uses of Magnetic Flow Meters

Examining specific applications shows why this technology remains essential:

Industry-Specific Implementations

| Sector | Primary Uses | Key Advantages | Emerging Requirements |

|---|---|---|---|

| Water Treatment5 | Inflow/outflow monitoring | Handles dirty water with solids | ±2% accuracy for dosing |

| Chemical Plants6 | Acid/base flow measurement | Resists corrosion | High-temperature capability |

| Mining | Slurry pipeline management | Withstands abrasive particles | Remote monitoring needs |

| Food & Beverage7 | Hygienic liquid transfer | Clean-in-place design | Compliance with food standards |

Future developments focus on meeting tighter accuracy requirements while adding smart features like predictive maintenance alerts and integration with industrial IoT systems.

Conclusion

Electromagnetic flow meters accurately measure conductive liquids like water and acids but exclude oils and gases. Their importance grows as industries demand ±2% precision in critical fluid management applications.

Learn about electrically conductive liquids and their significance in industries that utilize flow measurement technologies. ↩

Discover how conductive particles influence flow measurement and the types of fluids suitable for electromagnetic flow meters. ↩

Identifying measurement challenges helps in selecting the right tools and methods for accurate fluid analysis in various industries. ↩

Identifying non-conductive liquids is essential for proper equipment use and to prevent measurement errors in industrial applications. ↩

Explore advancements in water treatment technologies to understand how they enhance efficiency and safety in managing water resources. ↩

Learn about the safety measures and technologies used in chemical plants to improve operational efficiency and reduce risks. ↩

Discover best practices in the food and beverage industry to ensure compliance with safety standards and enhance product quality. ↩