Pressure measurement

A pressure transmitter is an industrial instrument used to measure the pressure of gases, liquids, or other media in a system and convert it into an electrical signal (typically 4-20 mA, 0-10 V, or digital signals like HART, Foundation Fieldbus, or Profibus) that can be transmitted to a control system, display, or other devices for monitoring and control purposes.

Differential Pressure Transmitter

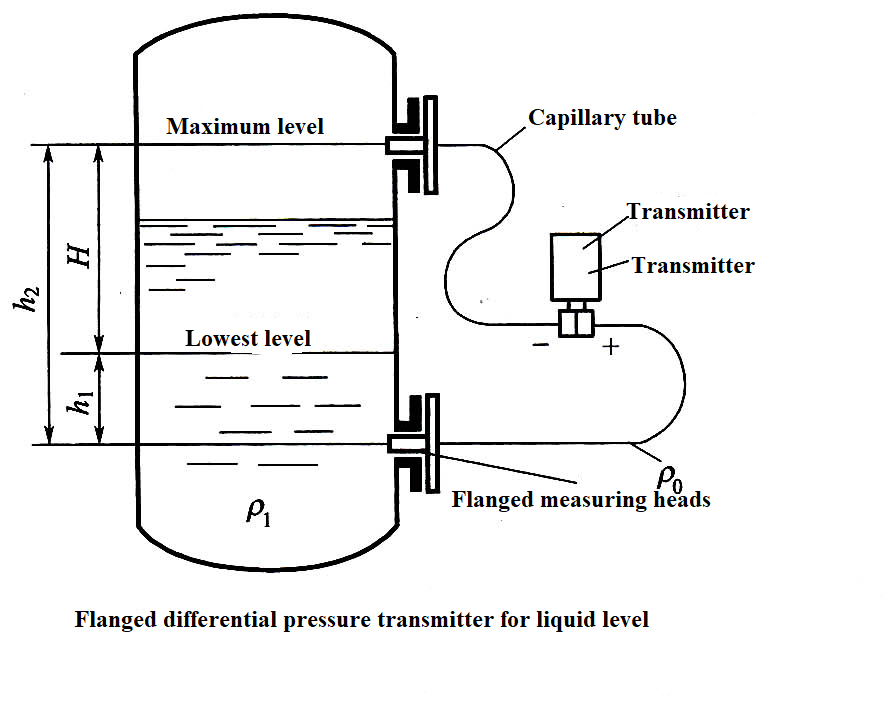

Remote Single Flange Differential Pressure Transmitter

Remote Double Flange Differential Pressure Transmitter

Intelligent Display Pressure Transmitter

Pressure Transmitter

pressure transmitter

Aviation Pressure Transmitter

Intelligent Pressure Controller

All You Need to know About pressure transmitter

Differential Pressure transmitter Principle

The DP transmitter measures pressure by comparing the forces exerted by two pressure inputs (P1 and P2) on a sensing element. The difference between these pressures (ΔP = P1 – P2) is the differential pressure, which is then converted into an electrical signal proportional to this difference.

- Pressure Application:

- The two process pressures (P1 and P2) are applied to the high and low-pressure ports.

- Force Comparison:

- The diaphragm deflects due to the difference in pressure (ΔP = P1 – P2).

- Diaphragm Deflection:

- The amount of deflection is proportional to the differential pressure.

- Signal Conversion:

- The deflection is detected by the transducer and converted into an electrical signal.

- Output Signal:

- The transmitter outputs a signal (e.g., 4-20 mA) proportional to the differential pressure.

- Transmission to Control System:

- The signal is sent to a control system, display, or recorder for further processing.

pressure Transmitter

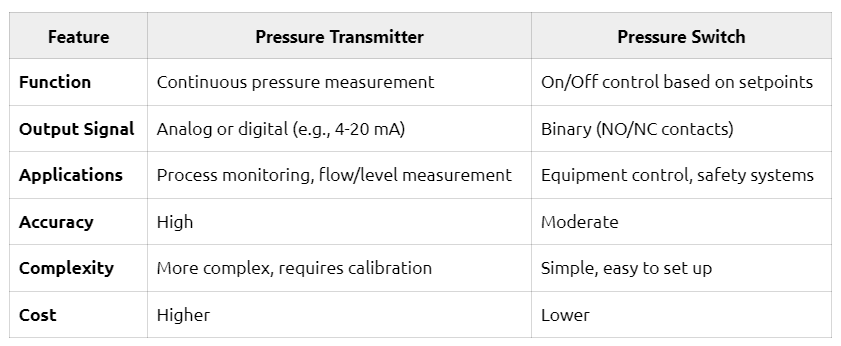

vS

pressure switch

A Pressure Transmitter is a device that continuously measures pressure and converts it into an analog (e.g., 4-20 mA) or digital signal for real-time monitoring and control. It is ideal for applications requiring precise, continuous data, such as process industries, flow/level measurement, and data logging. In contrast, a Pressure Switch is a simple binary device that activates or deactivates an electrical circuit when pressure reaches a predefined setpoint. It is commonly used for on/off control in equipment like pumps, compressors, and safety systems. While transmitters offer high accuracy and integration with control systems, switches are cost-effective, easy to install, and ideal for basic threshold-based operations.

pressure transmitter application

- Industrial Process Control: Monitors fluid/gas pressure in pipelines, ensuring optimal operation in chemical, oil & gas, and manufacturing plants.

- HVAC Systems: Measures pressure in heating, ventilation, and air conditioning systems for efficiency.

- Water Treatment: Tracks water pressure in filtration, pumping, and distribution systems.

- Hydraulics & Pneumatics: Ensures accurate pressure control in machinery and equipment.

- Aerospace: Monitors cabin and fuel pressure in aircraft systems.

- Automotive: Measures tire pressure, engine oil pressure, and brake systems.

- Energy & Power: Tracks steam, gas, and coolant pressure in power plants.

Production Process