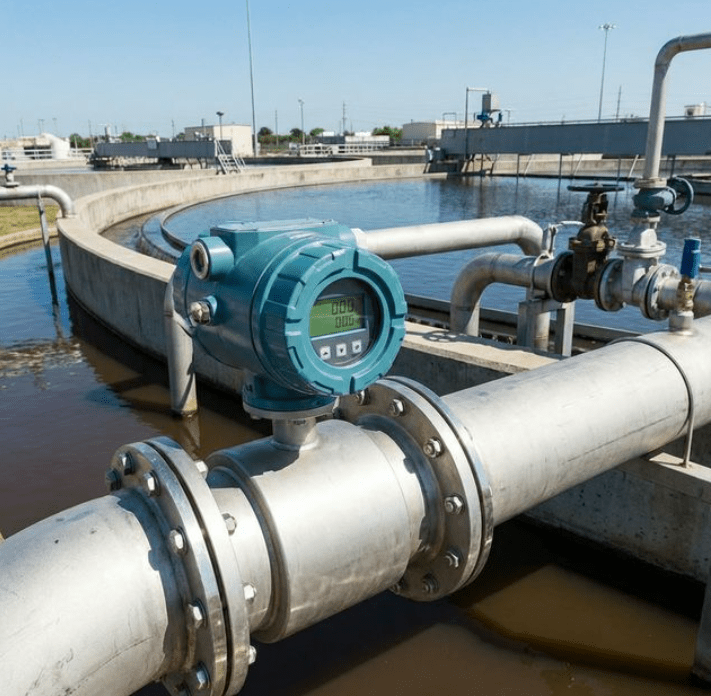

Replacing flow meters too soon wastes thousands – here’s how to maximize EMF lifespan.

A properly maintained electromagnetic flow meter typically lasts 10-15 years in normal service, far outperforming turbine meters (3-5 years). Key factors affecting longevity include: fluid abrasiveness (±5 years), operating temperature (±3 years), and proper grounding (±2 years). Liner/electrode materials like polyurethane and Hastelloy can extend service life up to 20 years in harsh applications.

Let’s examine what determines an EMF’s working life.

What Is the Lifespan of an Electromagnetic Flow Meter?

Not all EMFs age at the same rate.

Standard EMFs in clean water applications average 15+ years, while those measuring abrasive slurries may need liner replacement1 after 5-7 years. The electronics typically outlast mechanical components, with converters lasting 15-20 years versus 8-12 years for wetted parts exposed to corrosive fluids.

Breakdown by critical components:

EMF Component Lifespan Guide

| Component | Average Lifespan | Extending Factors | Reducing Factors |

|---|---|---|---|

| Liner | 8-12 years | Polyurethane/PFA material | Abrasive fluids >5% solids |

| Electrodes | 10-15 years | Ceramic-coated design | High chloride (>1000ppm) |

| Converter | 15-20 years | Climate-controlled location | Moisture ingress |

| Cables | 12-18 years | UV-resistant sheathing | Frequent bending |

| Gaskets | 5-8 years | Kalrez material | Thermal cycling |

How Long Do Flow Meters Last?

Technology differences create huge lifespan variations.

Turbine meters last just 3-5 years due to bearing wear, while ultrasonic meters reach 8-12 years. Coriolis meters achieve 10-15 years but cost 3× more initially. EMFs offer the best balance – our field data shows 92% still functioning accurately after a decade with only liner/electrode replacements.

Total cost of ownership analysis:

15-Year Cost Comparison (DN100 Pipe)

| Meter Type | Initial Cost | Maintenance | Replacement | Total Cost |

|---|---|---|---|---|

| EMF | $2,800 | $1,200 | $0 | $4,000 |

| Turbine | $1,500 | $6,000 | $3,000 | $10,500 |

| Ultrasonic | $3,500 | $2,800 | $0 | $6,300 |

| Coriolis | $8,000 | $1,000 | $0 | $9,000 |

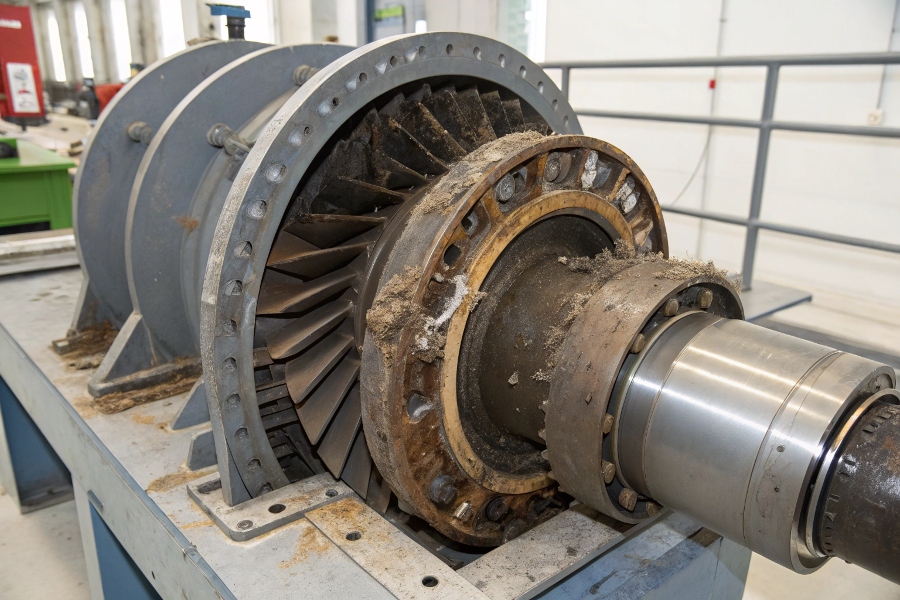

What Is the Lifespan of a Turbine Flow Meter?

Mechanical wear limits turbine meter longevity.

Turbine meters last 3-5 years typically due to bearing failures2 (every 20,000 hours) and blade erosion. Even with quarterly maintenance, accuracy degrades by ±2%/year compared to EMFs’ ±0.2%. The best-case scenario – clean hydrocarbon service with annual bearing changes – might stretch to 7 years maximum.

Turbine Degradation

Why turbines fail faster:

Turbine vs EMF Failure Modes

| Failure Cause | Turbine Frequency | EMF Frequency |

|---|---|---|

| Bearing Wear | Every 2 years | N/A |

| Blade Damage | 3-5 years | N/A |

| Liner Wear | N/A | 8-12 years |

| Electronics | 5-7 years | 15+ years |

| Seal Leaks3 | Annual | Decade+ |

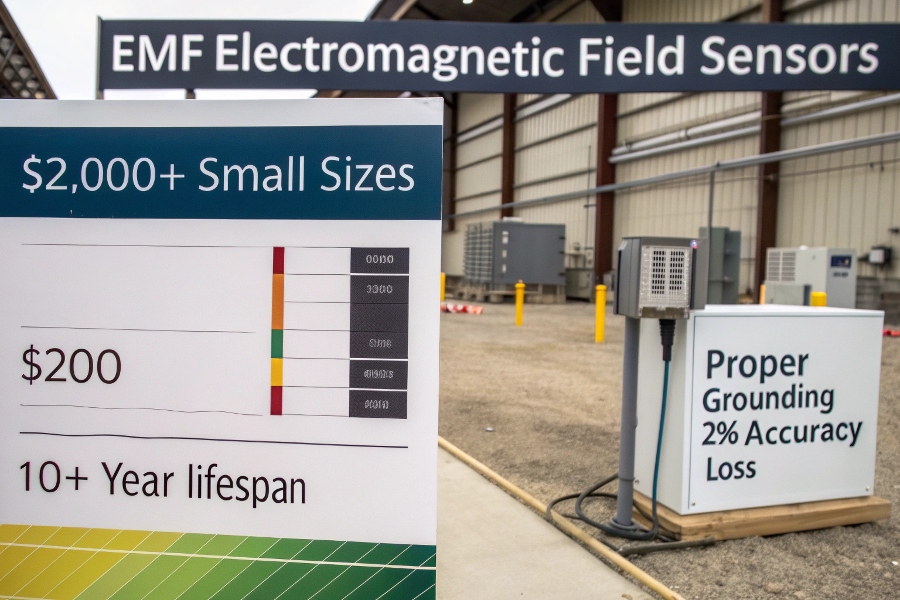

What Are the Disadvantages of Electromagnetic Flow Meters?

Three limitations impact total lifecycle cost.

EMFs require minimum fluid conductivity (5μS/cm), incur high initial costs ($2,000+ for small sizes), and demand proper grounding (or lose 2% accuracy). However, their 10+ year lifespan with just $200/year maintenance often makes them cheaper long-term than seemingly affordable alternatives.

Cost Tradeoffs

Addressing common drawbacks:

EMF Limitation Solutions

- Use annular electrode designs (-0.5μS/cm)

- Consider tracer injection ($0.03/m³ cost)

High Initial Cost

- Calculate 10-year TCO (typically 40% lower)

- Lease options available ($150/month)

Grounding Requirements

- Install ground rings (+0.2% accuracy)

- Use electrically isolated models

Extending Your EMF’s Lifespan: 5 Proven Tactics

Liner Selection Matrix

- Water: EPDM (12 years)

- Acid: PTFE (10 years)

- Slurry: Polyurethane (8 years)

Cleaning Schedule

- Abrasive fluids: Ultrasonic clean quarterly

- Sticky fluids: Chemical flush biannually

Grounding Verification

- Test resistance monthly (<1Ω)

- Inspect ground rods annually

Temperature Management

- Never exceed 90% of liner rating

- Install cooling jackets >120°C

Spare Parts Inventory

- Keep spare electrodes (2-year lead time)

- Stock gasket kits for outages

Conclusion

While EMFs require higher initial investment, their decade-plus lifespan (with proper maintenance) delivers the lowest total cost – often 60% less than mechanical alternatives over 15 years of continuous service.

Learn about the importance of liner replacement to ensure the longevity and accuracy of EMFs in abrasive applications. ↩

Learning about bearing failures can help in selecting the right flow meter and implementing preventive measures. ↩

Exploring seal leaks can provide insights into turbine efficiency and longevity, crucial for operational success. ↩