Corrosive liquids can quickly destroy standard flow meters, leading to costly replacements and dangerous leaks.

For corrosive liquids, magnetic flowmeters with corrosion-resistant liners, non-intrusive ultrasonic meters, or specially-coated Coriolis meters are the most reliable options.

Flow Meters for Corrosive Liquids

"

Let me share my expertise in handling corrosive fluid measurements.

Which Flow Meters Are Best for Measuring Corrosive Liquids?

Many facilities face challenges with premature meter failure in corrosive applications.

Magnetic flowmeters with PTFE or PFA liners, clamp-on ultrasonic meters, and Coriolis meters with Hastelloy or tantalum wetted parts excel in corrosive environments.

Corrosive Fluid Measurement Solutions

From my experience with corrosive applications:

Material Compatibility

Liner Materials

Material Resistance Applications PTFE Excellent Strong acids PFA Superior Chlorine PEEK Good Mild corrosives Ceramic Excellent Abrasives Body Materials

- Hastelloy options

- Tantalum construction

- Special alloys

- Composite materials

Selection Criteria

Application Factors

- Chemical composition

- Temperature range

- Pressure conditions

- Flow requirements

Operational Aspects

- Maintenance needs

- Replacement costs

- Safety considerations

- Performance monitoring

What Type of Flow Meter Works Best with High Viscous Fluid?

Viscous fluids challenge many traditional flow measurement technologies.

Positive displacement meters, Coriolis meters, and specially designed ultrasonic meters are most suitable for high-viscosity fluid measurement.

High Viscosity Flow Measurement

Based on my viscous fluid expertise:

Viscous Flow Solutions

Technology Comparison

Meter Type Viscosity Range Benefits PD Meters Up to 1M cP Direct volume Coriolis No limit Mass flow Ultrasonic Up to 300 cP Non-intrusive Oval Gear Up to 1M cP High accuracy Application Considerations

- Temperature effects

- Pressure drops

- Maintenance access

- Cleaning requirements

Implementation Strategy

Design Phase

- Viscosity analysis

- Temperature impact

- Pressure calculations

- Size optimization

Installation Planning

- Heating requirements

- Support structures

- Maintenance access

- Cleaning systems

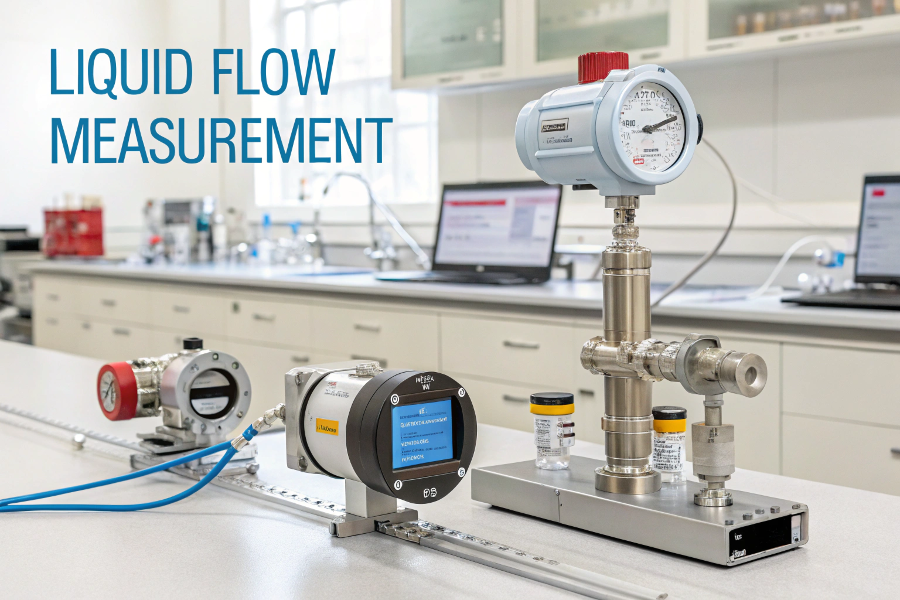

How Do You Measure the Flow of a Liquid?

Different liquids require specific measurement approaches.

Liquid flow measurement involves selecting appropriate technology based on fluid properties, required accuracy, and process conditions.

Liquid Flow Measurement Methods

Drawing from my measurement experience:

Measurement Methods

Technology Selection

Method Application Limitations Magnetic Conductive Non-conductive Ultrasonic Clean liquids High solids Coriolis Universal Cost Vortex Clean liquids Low flows Implementation Factors

- Installation requirements

- Accuracy needs

- Maintenance access

- Cost considerations

Best Practices

System Design

- Flow analysis

- Material selection

- Size optimization

- Installation planning

Operational Planning

- Startup procedures

- Maintenance schedules

- Calibration plans

- Training requirements

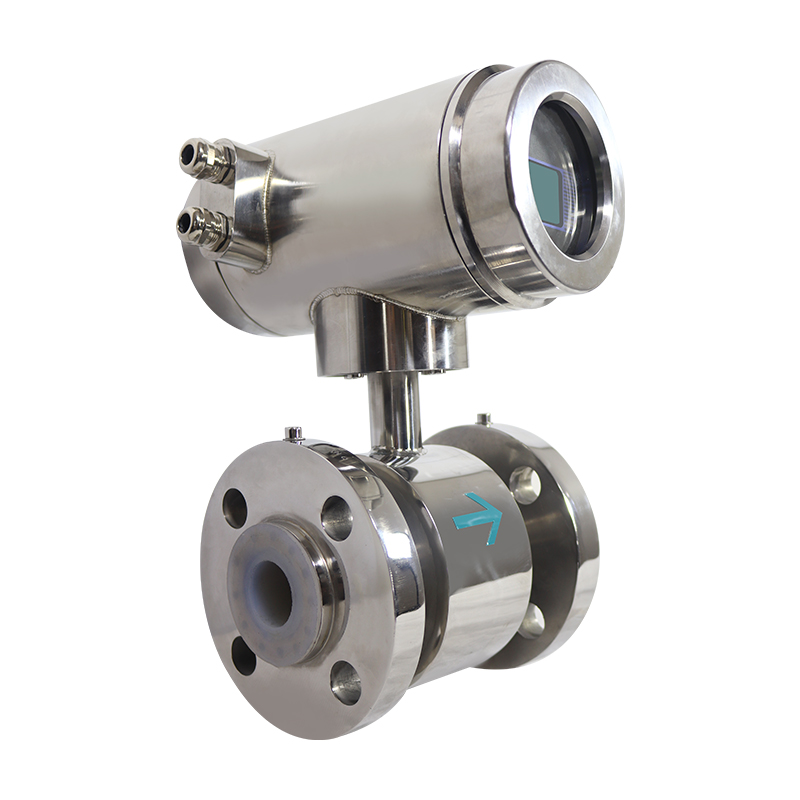

What Type of Fluids Can Magnetic Flow Meters Measure?

Understanding magnetic flowmeter capabilities prevents application mistakes.

Magnetic flowmeters can measure any conductive liquid with conductivity above 5 µS/cm, including water, chemicals, slurries, and pulp.

Magnetic Flow Meter Applications

Based on my magnetic flow expertise:

Application Guide

Fluid Requirements

Property Requirement Examples Conductivity >5 µS/cm Water Solids Up to 70% Slurries Viscosity No limit Pastes Temperature -40 to 180°C Hot fluids Application Limits

- Non-conductive liquids

- Air entrainment

- Coating potential

- Installation effects

Implementation Tips

Installation Planning

- Grounding requirements

- Pipe configuration

- Electrode selection

- Liner choice

Operational Aspects

- Regular verification

- Electrode cleaning

- Zero adjustment

- Performance monitoring

Conclusion

Successful corrosive liquid flow measurement requires careful consideration of material compatibility, fluid properties, and appropriate technology selection based on specific application requirements.