At a recent chemical plant installation, we faced significant measurement errors. After investigation, I discovered the root cause wasn’t equipment failure – it was a fundamental misunderstanding of how transit-time technology works.

A transit-time ultrasonic flow meter measures flow by calculating the difference in time it takes for ultrasonic signals to travel upstream versus downstream in a pipe. This time difference directly correlates to flow velocity.

Transit-Time Measurement Basic Principle

Let me share what I’ve learned from 15 years of working with ultrasonic technology, starting with a recent success story at a water treatment facility.

What’s the Core Working Principle Behind Transit-Time Technology?

Last month, while training a team at a beverage plant, they couldn’t understand why their readings varied with temperature. The answer lies in understanding the fundamental physics of ultrasonic measurement.

Transit-time ultrasonic flow meters work by comparing upstream and downstream signal travel times. When liquid flows faster, the difference between these times increases. The meter uses this difference to calculate flow rate using the equation: V = K(1/t₁ – 1/t₂).

Understanding Signal Propagation

Wave Physics in Flowing Media

Parameter Description Impact on Measurement Typical Values Sound Speed1 Velocity in medium Affects transit time 1,400-1,600 m/s Flow Velocity2 Liquid speed Changes time difference 0-10 m/s Path Angle Signal trajectory Affects sensitivity 45-60 degrees Path Length Total distance Determines resolution Pipe diameter dependent

What Components Make Up a Transit-Time Flow Meter?

During a recent petrochemical plant upgrade, we had to replace several components. This experience perfectly illustrates the critical role of each part.

Transit-time flow meters consist of paired transducers, a signal processor, mounting hardware, and display unit. Each component plays a vital role in converting sound wave travel times into accurate flow measurements.

Component Analysis

Transducer Technology

Component Function Critical Features Maintenance Needs Piezo Crystal3 Generate signals Frequency response Annual inspection Housing Protection Environmental rating Cleaning Coupling Signal transfer Acoustic matching Regular check Electronics Signal processing4 Data conversion Calibration Signal Processing System

- Analog-to-digital conversion

- Time difference calculation

- Flow rate computation

- Data filtering and averaging

How Are Different Installation Configurations Implemented?

I recently solved a difficult installation challenge at a confined space in a food processing plant by switching from V-path to W-path configuration.

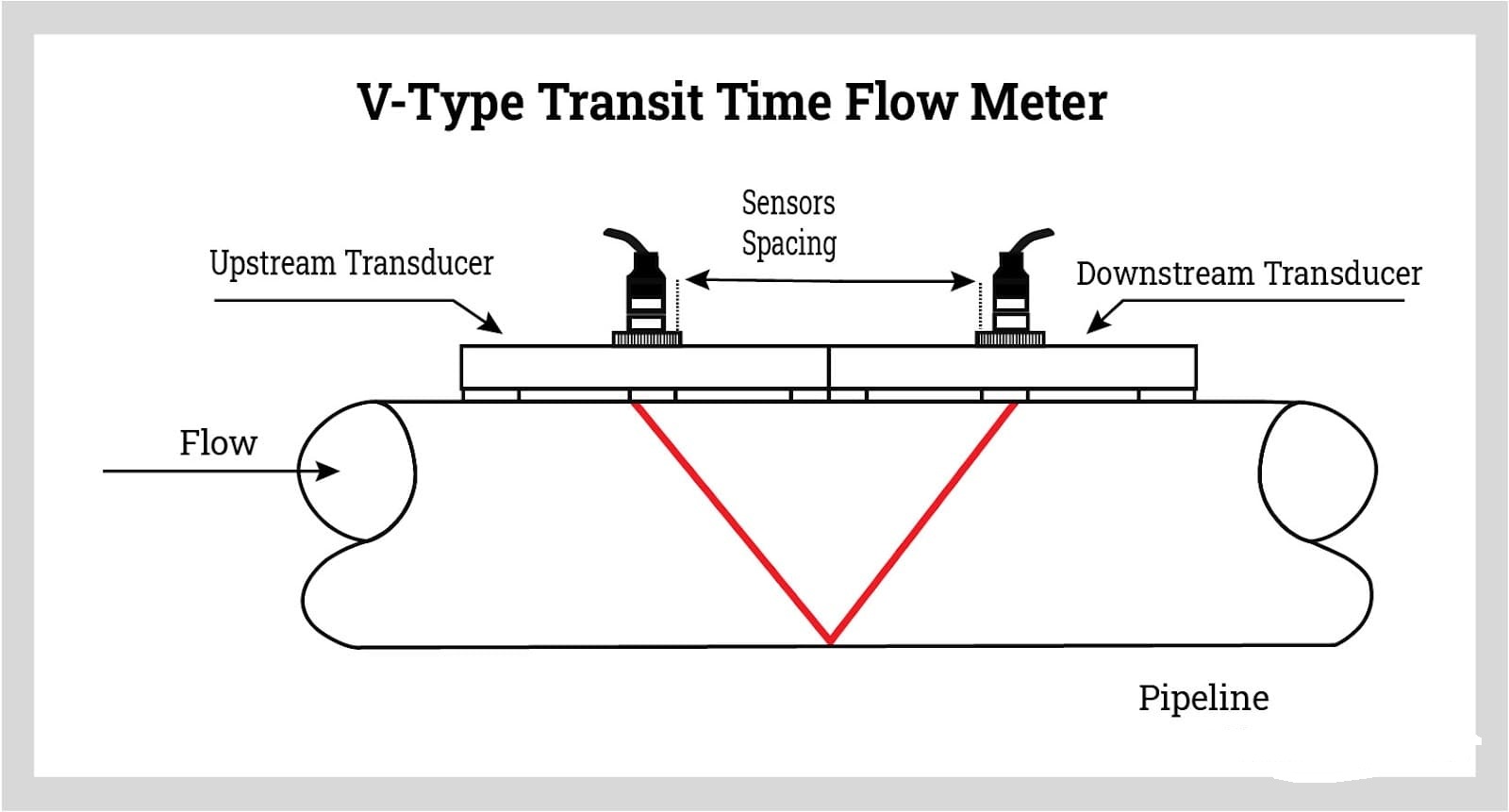

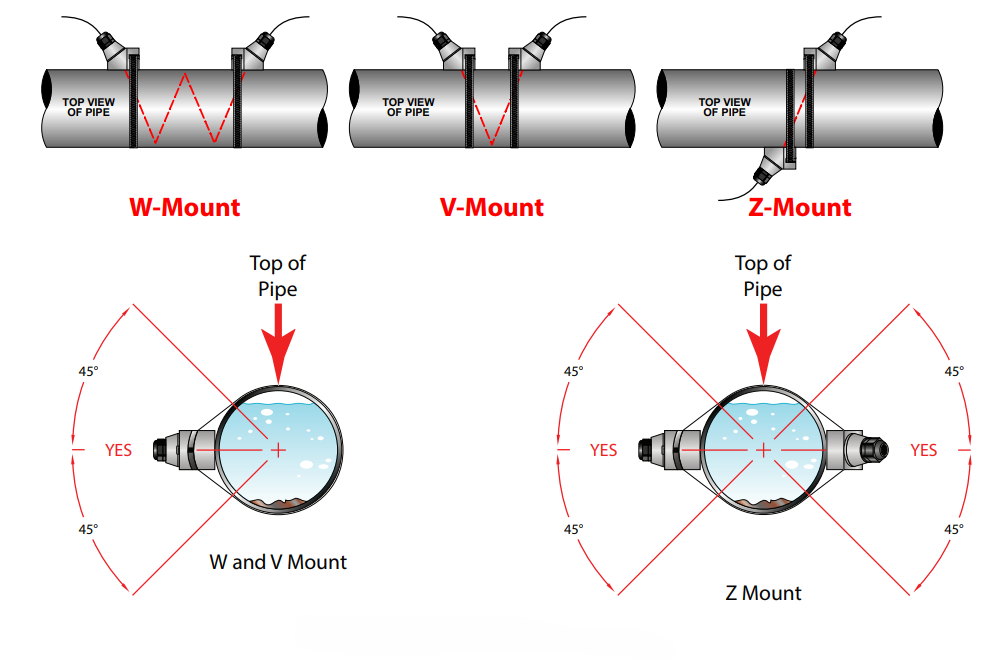

Transit-time meters can be installed in various configurations: V-path, W-path, and Z-path. Each configuration offers different benefits for accuracy and installation flexibility based on pipe size and access limitations.

Installation Configuration Options

Installation Methods Comparison

| Configuration | Advantages | Limitations | Best Applications |

|---|---|---|---|

| V-Path | Easy installation | Limited resolution | Standard pipes |

| W-Path | Higher accuracy | Complex setup | Small pipes |

| Z-Path | Direct measurement | Access both sides | Large pipes |

How Is Flow Data Calculated and Processed?

A pharmaceutical client recently questioned their flow accuracy. By explaining the calculation process, we identified and corrected a parameter setting error.

Flow calculation involves measuring upstream and downstream transit times, applying temperature compensation, and using calibration factors. The processor converts time differences into velocity using sophisticated algorithms.

Data Processing Steps

Signal Analysis

Step Process Quality Checks Error Handling Time Measurement Nanosecond precision Signal strength Auto-retry Velocity Calculation Algorithm processing Profile factor Averaging Temperature Comp Real-time adjustment Sensor check Alerts Output Generation Signal conversion Range verification Error codes

Conclusion

Understanding transit-time ultrasonic flow meter operation is crucial for proper implementation and troubleshooting. From basic principles to advanced configurations, each aspect contributes to measurement accuracy.

Looking for specific guidance on your application? Contact our technical team for personalized support and solutions.

Understanding sound speed is crucial for accurate measurements in wave physics, affecting transit time significantly. ↩

Exploring flow velocity helps in grasping its effect on time differences, essential for precise wave measurement. ↩

Understanding the role of Piezo Crystals can enhance your knowledge of signal generation in various applications. ↩

Exploring signal processing systems will provide insights into how data is transformed and utilized in technology. ↩